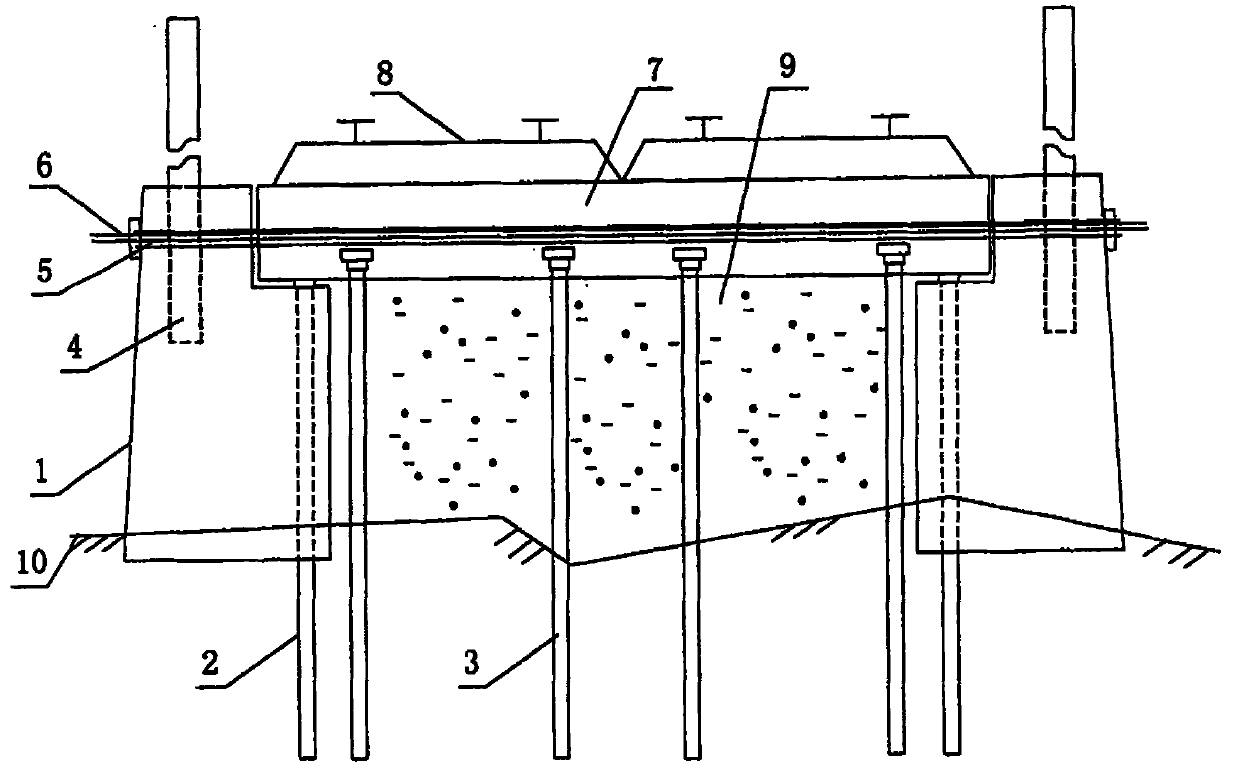

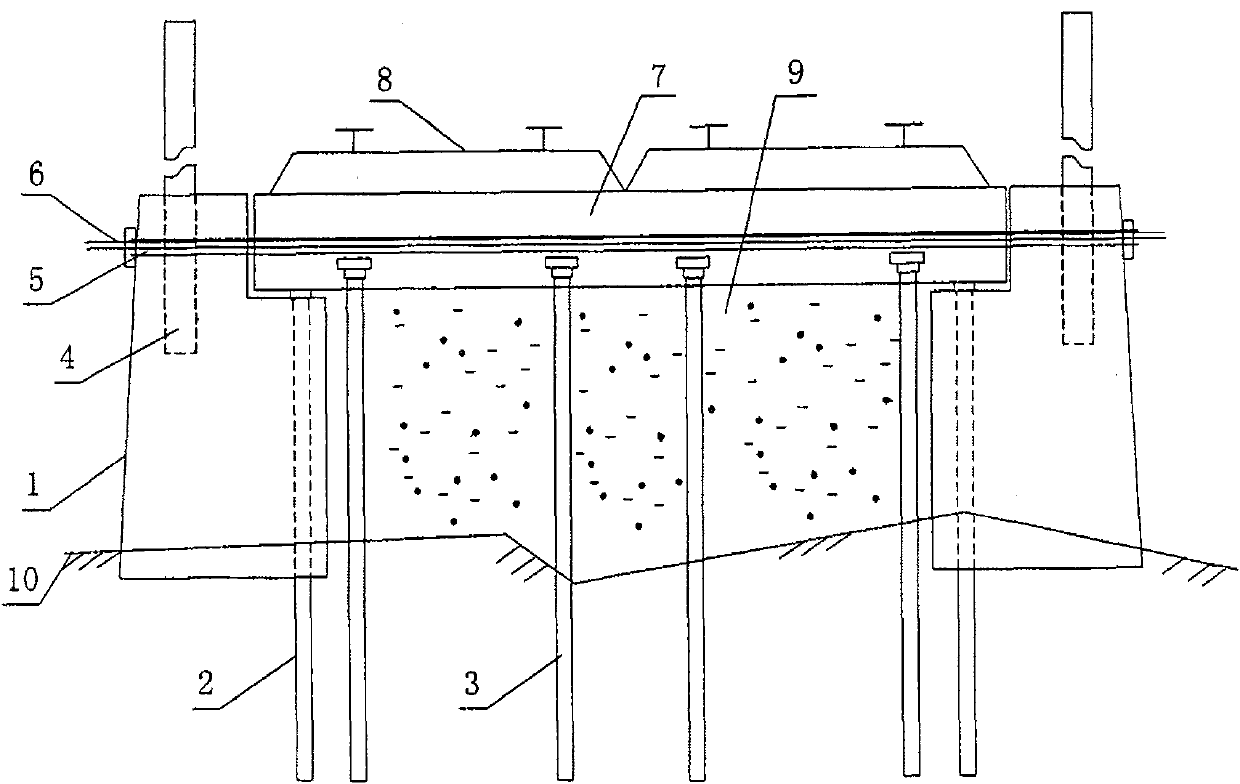

CFG pile, pipe pile embankment reinforcement system and construction method thereof

A construction method and pipe pile technology, which can be applied to roads, sheet pile walls, and foundation structure engineering, etc., can solve the problems of difficult degradation of concrete pile heads, high requirements for embankment filling specifications, and long construction period, so as to achieve filling and compaction The effect of low requirements, small scope of base reinforcement, and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Construction method embodiment 1 of CFG pile, pipe pile embankment reinforcement system: in the following order

[0029] 1. Carry out the construction of bottom pipe piles or one row of pipe piles or CFG piles on both sides of the support structure;

[0030] 2. Arrange steel bars, formwork, pour concrete for the retaining structure, and reserve the cup mouth of the electrochemical support and the prestressed anchor cable channel in the concrete for the retaining structure;

[0031] 3. The soil is compacted and filled to the bottom of the prestressed raft to build a pile foundation construction platform;

[0032] 4. Construction of 4 rows of pipe piles or CFG piles in the middle of the embankment;

[0033] 5. Clean up the prestressed raft foundation, and clean out the prestressed raft foundation groove on the pile foundation construction platform above the middle pipe pile or the middle CFG pile;

[0034] 6. Thread the prestressed anchor cable of the raft slab, lay out...

Embodiment 2

[0044] Construction method embodiment 2 of CFG pile, pipe pile embankment reinforcement system: in the following order

[0045] 1. Carry out the construction of bottom pipe piles or two rows of pipe piles or CFG piles on both sides of the support structure;

[0046] 2. Arrange steel bars, formwork, pour concrete for the retaining structure, and reserve the cup mouth of the electrochemical support and the prestressed anchor cable channel in the concrete for the retaining structure;

[0047] 3. The soil is compacted and filled to the bottom of the prestressed raft to build a pile foundation construction platform;

[0048] 4. Construction of 12 rows of pipe piles or CFG piles in the middle of the embankment;

[0049] 5. Clean up the prestressed raft foundation, and clean out the prestressed raft foundation groove on the pile foundation construction platform above the middle pipe pile or the middle CFG pile;

[0050] 6. Thread and pull the raft prestressed anchor cable, and lay ...

Embodiment 3

[0060] Construction method embodiment 3 of CFG pile, pipe pile embankment reinforcement system: in the following order

[0061] 1. Carry out the construction of bottom pipe piles or 3 rows of pipe piles or CFG piles on both sides of the support structure;

[0062] 2. Arrange steel bars, formwork, pour concrete for the retaining structure, and reserve the cup mouth of the electrochemical support and the prestressed anchor cable channel in the concrete for the retaining structure;

[0063] 3. The soil is compacted and filled to the bottom of the prestressed raft to build a pile foundation construction platform;

[0064] 4. Construction of 20 rows of pipe piles or CFG piles in the middle of the embankment;

[0065] 5. Clean up the prestressed raft foundation, and clean out the prestressed raft foundation groove on the pile foundation construction platform above the middle pipe pile or the middle CFG pile;

[0066] 6. Thread and pull the raft prestressed anchor cable, and lay ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com