Piston type double-acting multi-cylinder gas pumping apparatus of air compressor

A double-acting, multi-cylinder pump technology, applied in the field of machinery, can solve the problems of complex crankshaft manufacturing process, heavy weight, high cost ratio, etc., and achieve the effects of improved work efficiency and energy utilization, long service life and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

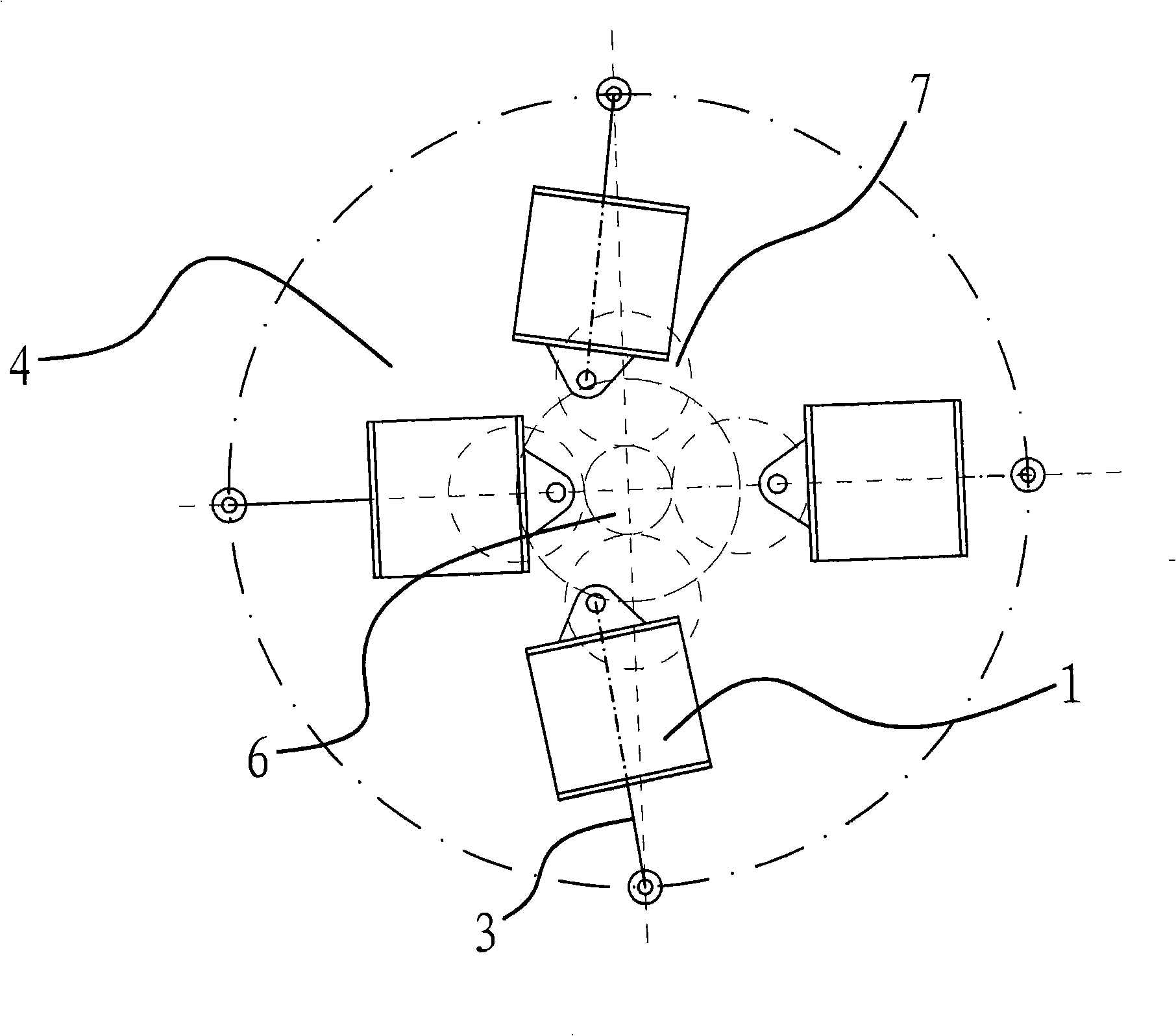

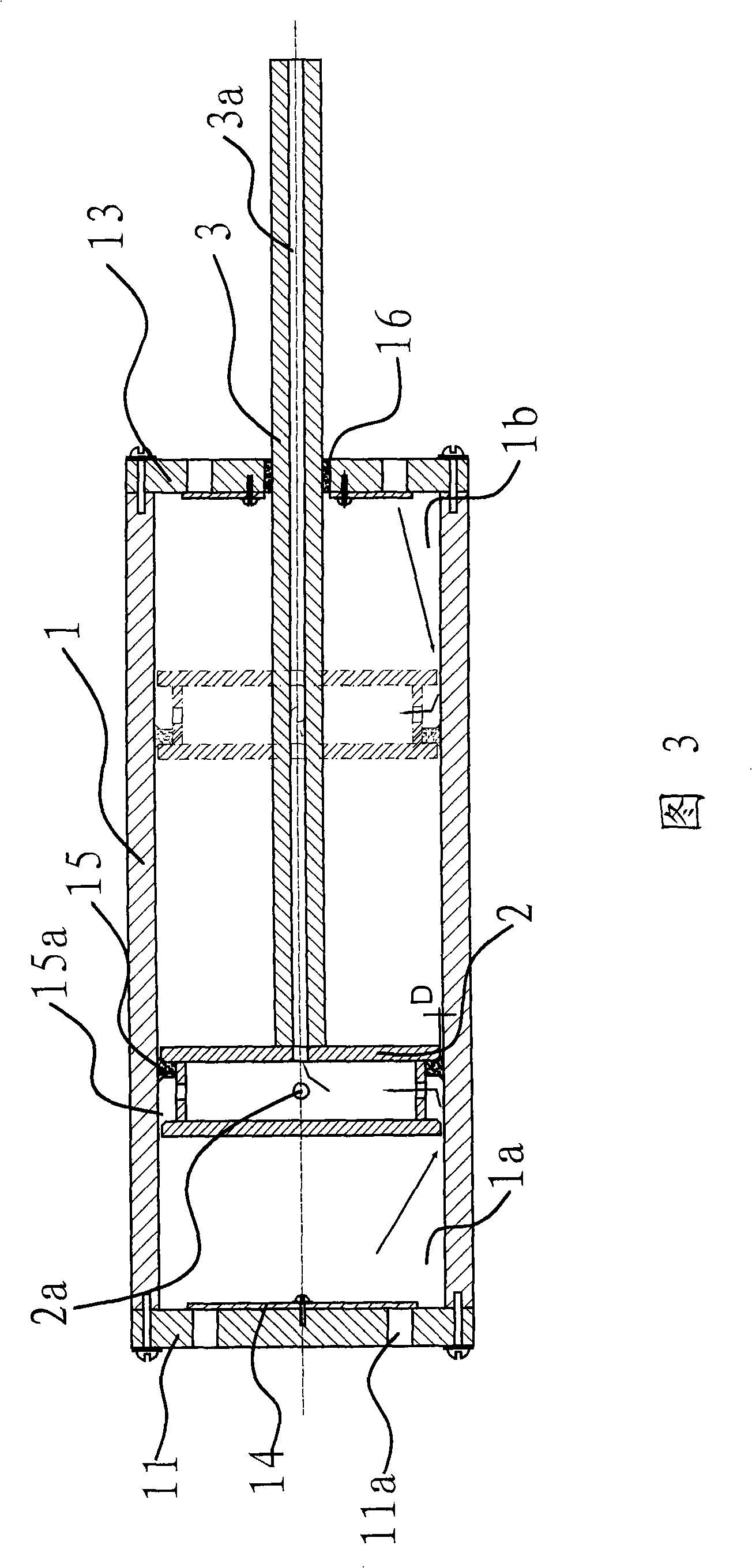

[0027] Such as figure 2 , Figure 3 and Figure 4 As shown, the piston-type double-acting multi-cylinder pumping device includes 4 cylinder blocks all composed of a piston 2, a piston rod 3 and a cylinder body 1. The piston 2 is located in the cylinder body 1 and is connected with one end of the piston rod 3. In one piece, the other end of the piston rod 3 extends out of the cylinder body 1 . The pumping device mainly drives the movement of the cylinder body 1, so that the piston 2 and the cylinder body 1 make a relative reciprocating linear motion and simultaneously reciprocate and swing.

[0028] The cylinder block used in this device has double functions. Specifically, the two ends of the cylinder block 1 are respectively connected with the left end cover 11 and the right end cover 13 by screws, and the left end cover 11 and the right end cover 13 have screw holes and are evenly distributed 16 air intake holes 11a. In order to reduce the negative impact of the dust in the...

Embodiment 2

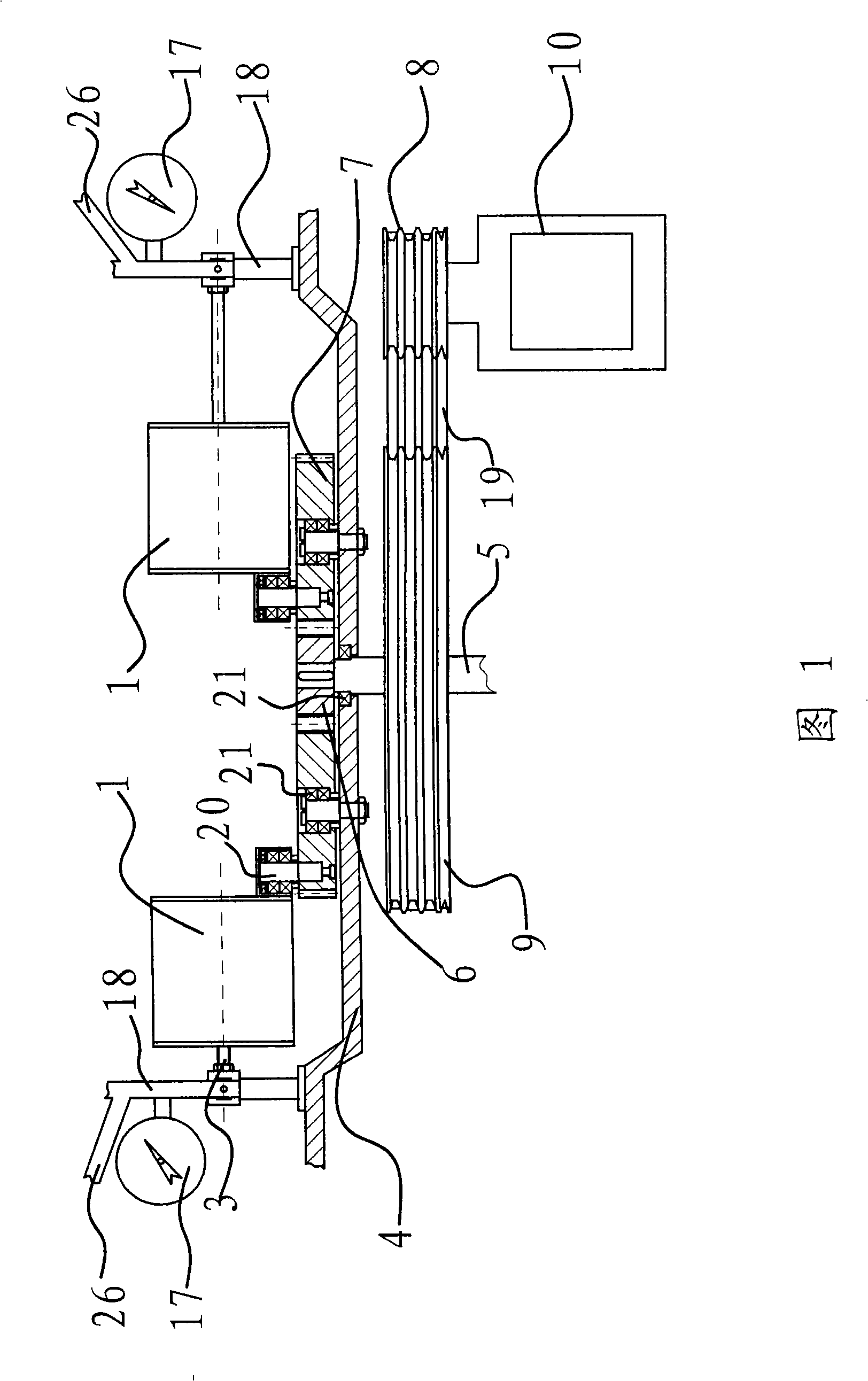

[0034] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: Figure 6 As shown, the piston-type double-acting multi-cylinder pumping device here is assembled by using multiple layers, and in this embodiment, it is assembled by using three layers. When assembling, the common main shaft 5 passes through multiple bases 4 at the same time, and in the corresponding Cylinder block, driving gear 6 and driven gear 7 etc. are installed on the base 4, wherein the cylinder block is arranged horizontally, and coupling joint 25 is set on the common main shaft 5 between adjacent layers here, convenient to assemble, and multilayer The pumping device of the pumping device shares a motor 10 or a hydraulic motor, a driving pulley 8 and a large-diameter driven pulley 9, and relies on the output power of the motor 10 to drive the main shaft 5 to rotate through the driving pulley 8 and the driven pulley 9, so that each layer pumps ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com