Method and strand-guiding device for guiding a cast strand

A guide device, continuous casting billet technology, applied in workpiece surface treatment equipment, metal rolling, manufacturing tools, etc., can solve problems such as dependence on cross-sectional form, improve casting speed and operating reliability, controllable, Small effect of abrasion and/or flame loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in detail below with reference to the above-mentioned drawings in the form of embodiments. The same technical features are indicated by the same reference numerals in all the drawings.

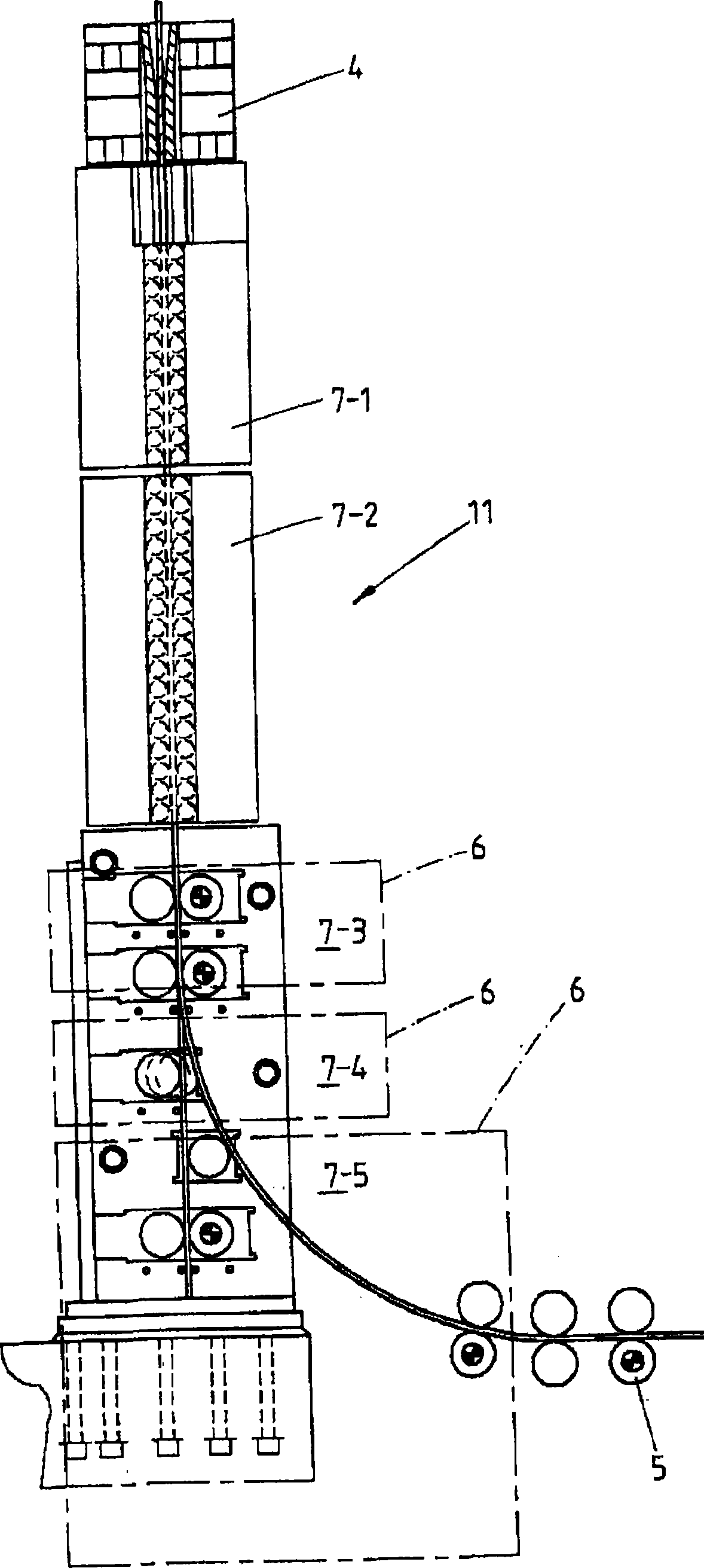

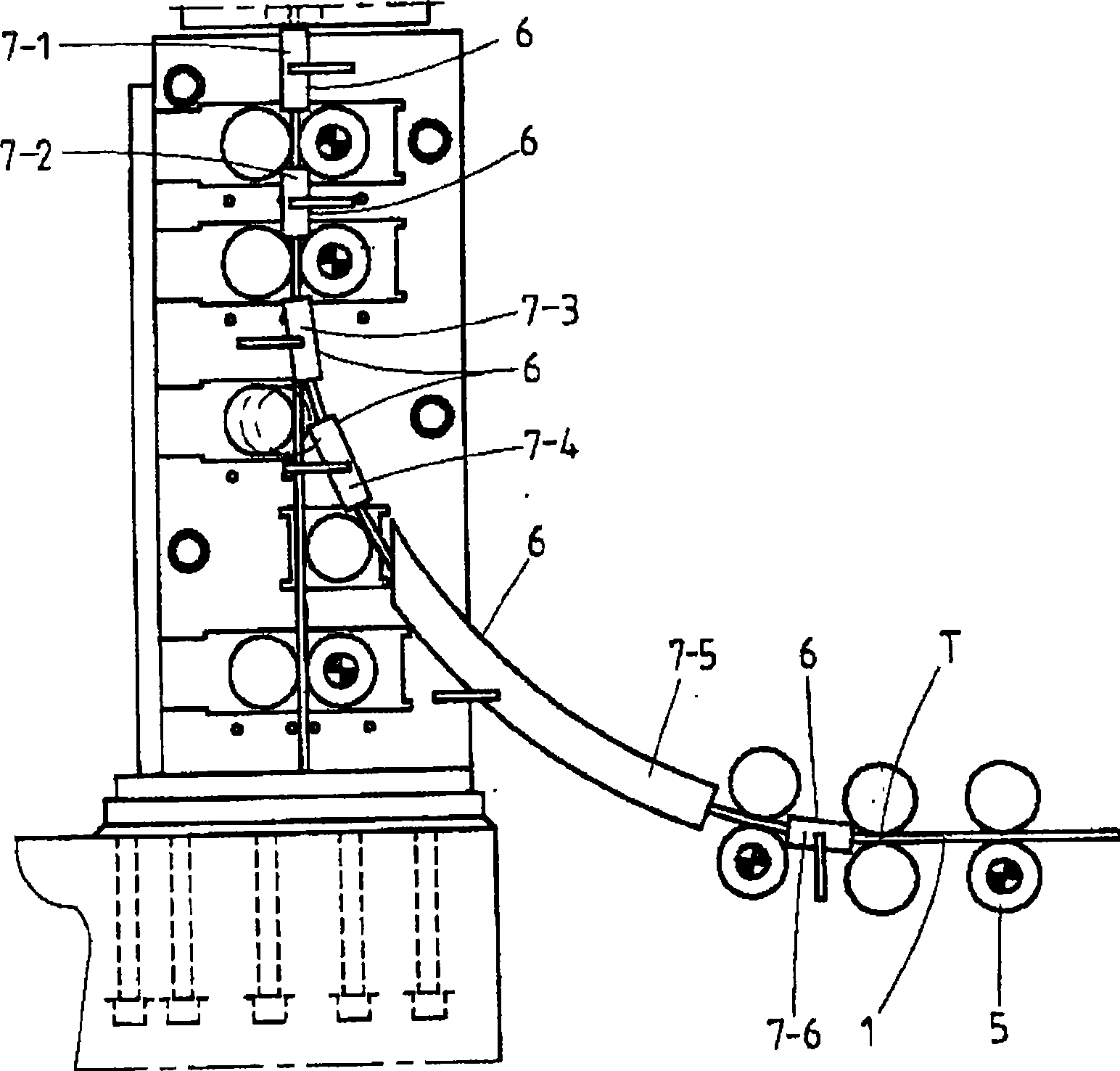

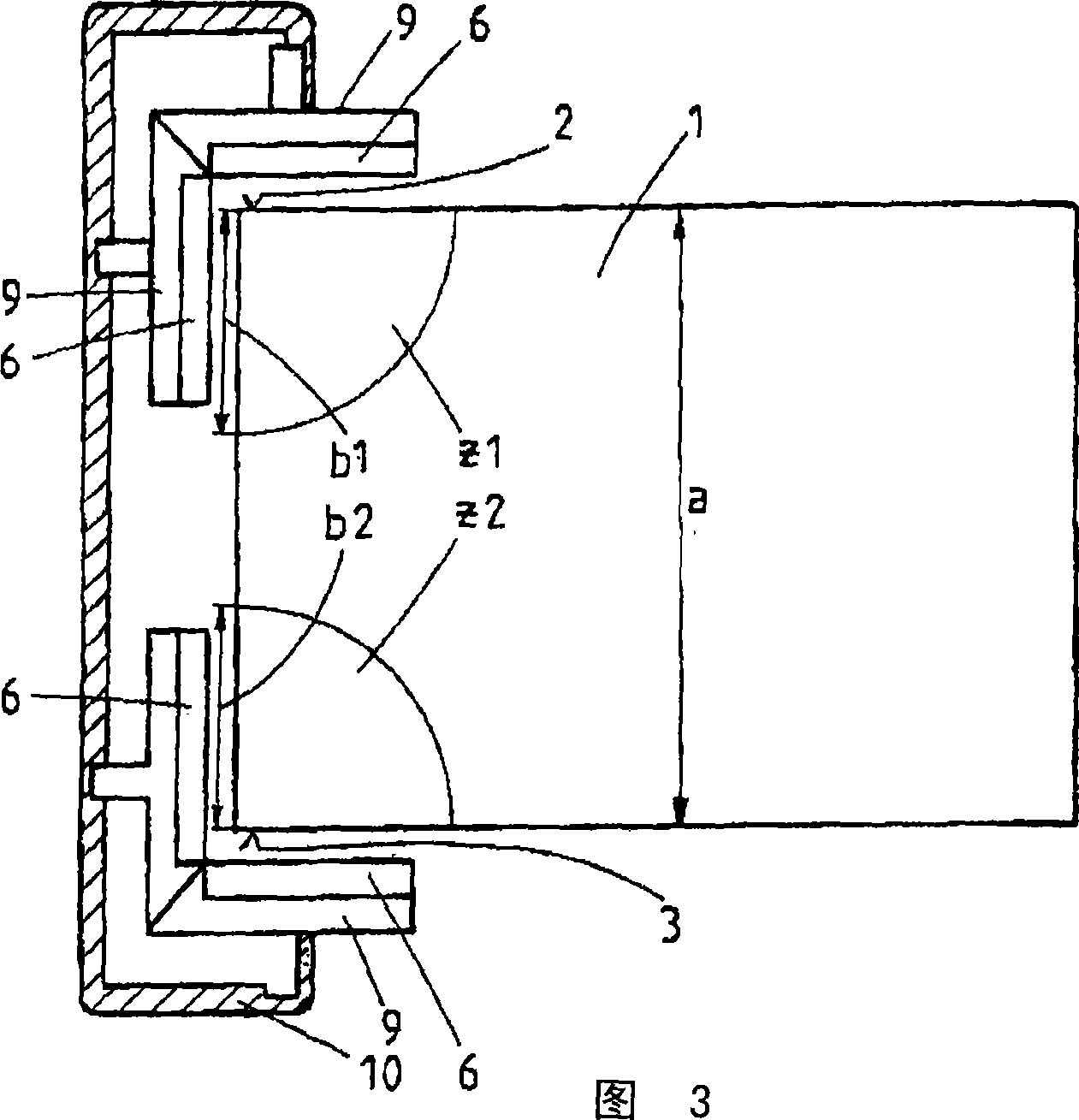

[0029] figure 1 Shown is a continuous casting machine with a mold 4 and a continuous casting slab guide 11 for supporting, guiding and annealing the continuous casting material, especially cast steel, also referred to below as the continuous casting slab 1. The continuous casting slab 1 according to the present invention is cast into a cross-sectional shape having at least edges 2, 3; see Figures 3 and Figure 4 .

[0030] according to figure 1 The edges 2, 3 on the narrow side of the continuous casting slab 1 in the area of the continuous casting slab guide between the exit of the mold 4 and the correction point of the straightening drive 5 are protected by the use of a large-area porous burner area 6 Heating, especially see figure 1 with figure 2 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com