Recycling method for recycled metal can and industrial production line device

A metal can, high-pressure water technology, applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of insufficient utilization, low added value of metal beverage cans, etc. Good demonstration and promotion significance, significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The method of the present invention mainly adopts the following steps to implement: a. Select the reclaimed metal can with no hard damage on the appearance. b. Dig a flat circular opening on the upper part of the metal tank; the position of the opening has two forms, one is to keep the curling mouth of the metal tank cover and the tank wall, and chisel all the tank cover Go, form a flat circular opening on the top of the tank; the second is to cut off the upper tank wall together with the tank cover, and form a flat circular opening on the tank wall, c. Clean the inner wall of the metal tank and then sterilize Dried and canned products; d. Put a new can lid on the circular opening of the can body, and seal it with a can seamer. finished metal cans.

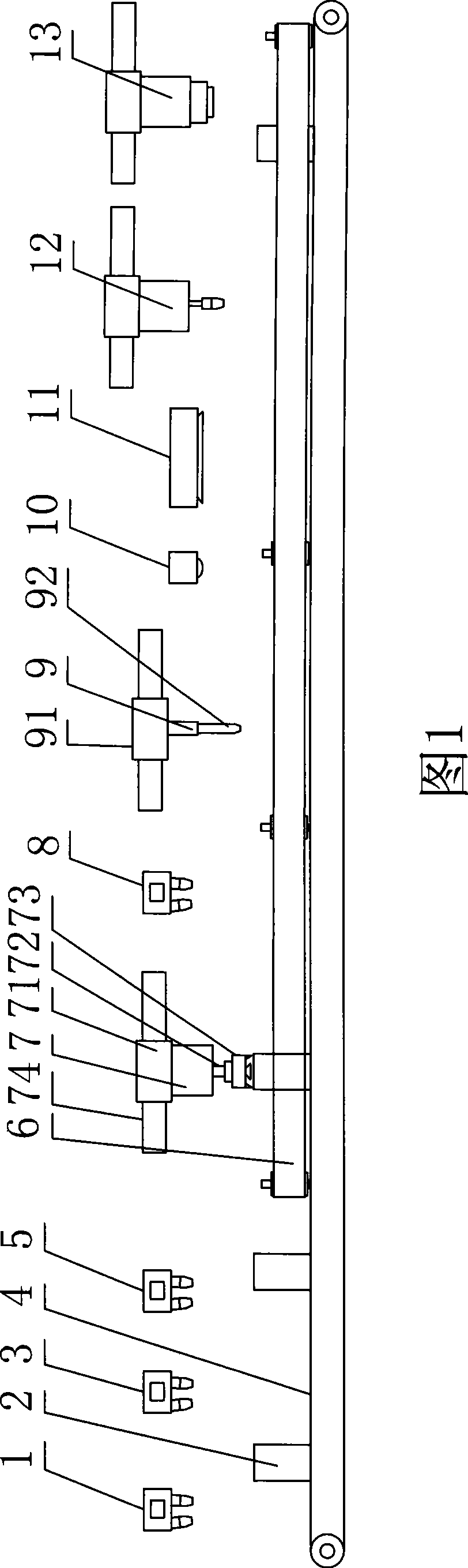

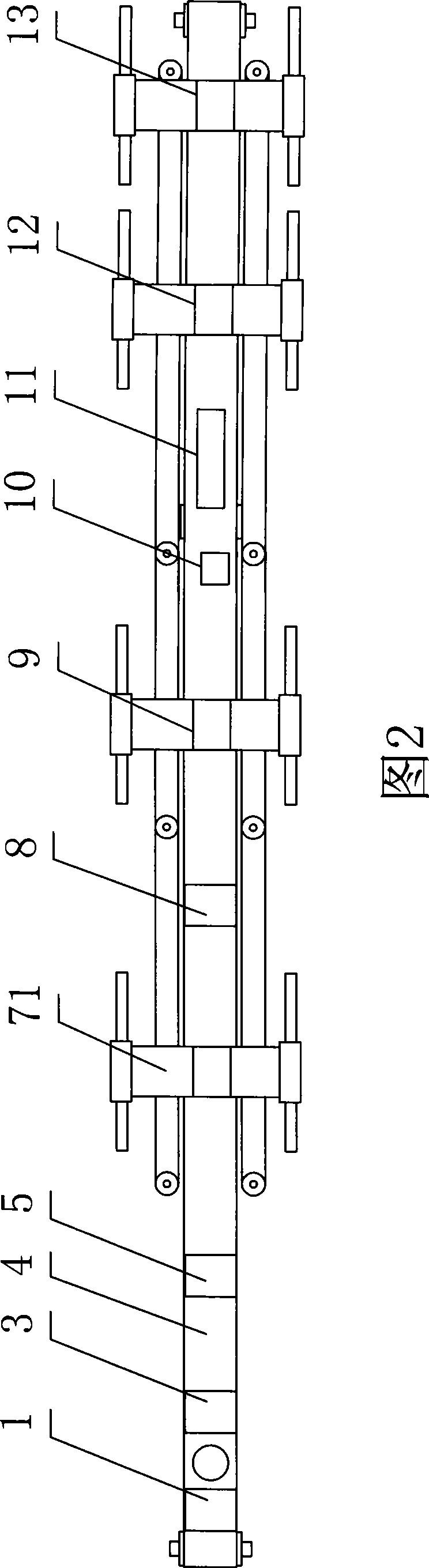

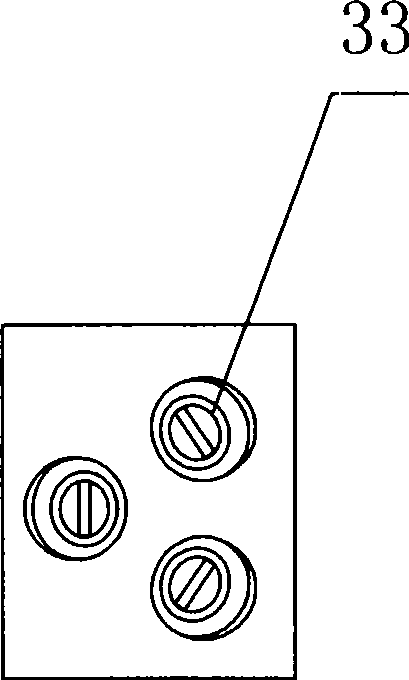

[0022] In order to realize the above method, it is necessary to specially design a kind of industrial assembly line equipment. Fig. 1 is a structural schematic diagram of a preferred embodiment of the industrial assembly l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com