Modified asphalt applying lake asphalt and preparation method thereof

A technology of modified asphalt and production method, which is applied in the direction of building components, building insulation materials, buildings, etc., which can solve problems affecting the stability of pavement and low-temperature cracking resistance, aging, environmental pollution, etc., to improve cracking resistance, anti-corrosion Enhanced oxidation resistance and improved durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

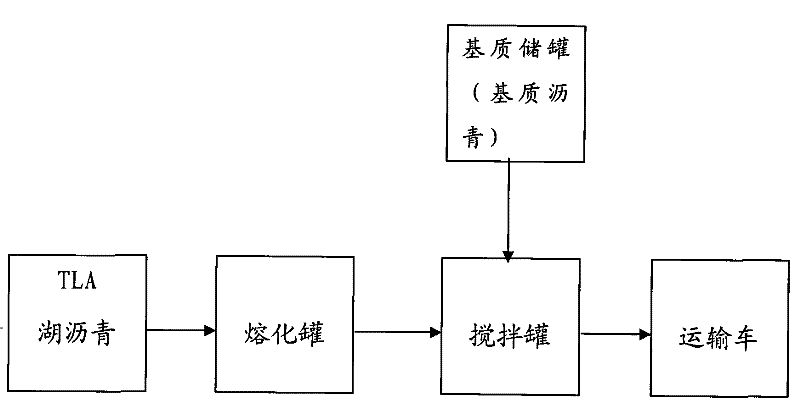

[0014] Embodiment 1: as figure 1 As shown, 1. Heat 7 tons (t) of AH-70 matrix asphalt in the matrix storage tank to 120°C.

[0015] 2. Put 3 tons of lake bitumen into the melting tank for complete melting at 165°C.

[0016] 3. Pump the base bitumen to the mixing tank; pump the TLA lake bitumen from the melting tank to the mixing tank.

[0017] 4. Turn on the agitator of the mixing tank to stir the mixture of matrix asphalt and TLA lake asphalt for 30 minutes, while the temperature in the mixing tank is kept at 170°C.

[0018] 5. After the mixing is completed, TLA lake asphalt and base asphalt are uniformly mixed, which is qualified modified asphalt for this application of lake asphalt.

Embodiment 2

[0019] Example 2: 1. Heat 9.5t of AH-70 base asphalt in the base storage tank to 130°C.

[0020] 2. Put 0.5t of lake bitumen into the melting tank for complete melting at 175°C.

[0021] 3. Pump the base bitumen to the mixing tank; pump the TLA lake bitumen from the melting tank to the mixing tank.

[0022] 4. Turn on the agitator of the mixing tank to stir the mixture of matrix asphalt and TLA lake asphalt for 20 minutes, while the temperature in the mixing tank is kept at 170°C.

[0023] 5. After the mixing is completed, TLA lake asphalt and base asphalt are uniformly mixed, which is qualified modified asphalt for this application of lake asphalt.

Embodiment 3

[0024] Example 3: 1. Heat 2t, AH-110 base asphalt in the base storage tank to 140°C.

[0025] 2. Put 8 tons of lake bitumen into the melting tank for complete melting at 195°C.

[0026] 3. Pump the base bitumen to the mixing tank; pump the TLA lake bitumen from the melting tank to the mixing tank.

[0027] 4. Turn on the agitator of the mixing tank to stir the mixture of matrix asphalt and TLA lake asphalt for 50 minutes, while the temperature in the mixing tank is kept at 170°C.

[0028] 5. After the mixing is completed, TLA lake asphalt and base asphalt are uniformly mixed, which is qualified modified asphalt for this application of lake asphalt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com