Testing machine for mattress durability

A technology of durability test and mattress, applied in the field of experiment and commodity inspection, can solve the problems of time-consuming and laborious operation, poor reliability, complex system, etc., and achieve the effect of improving measurement accuracy, high work efficiency and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

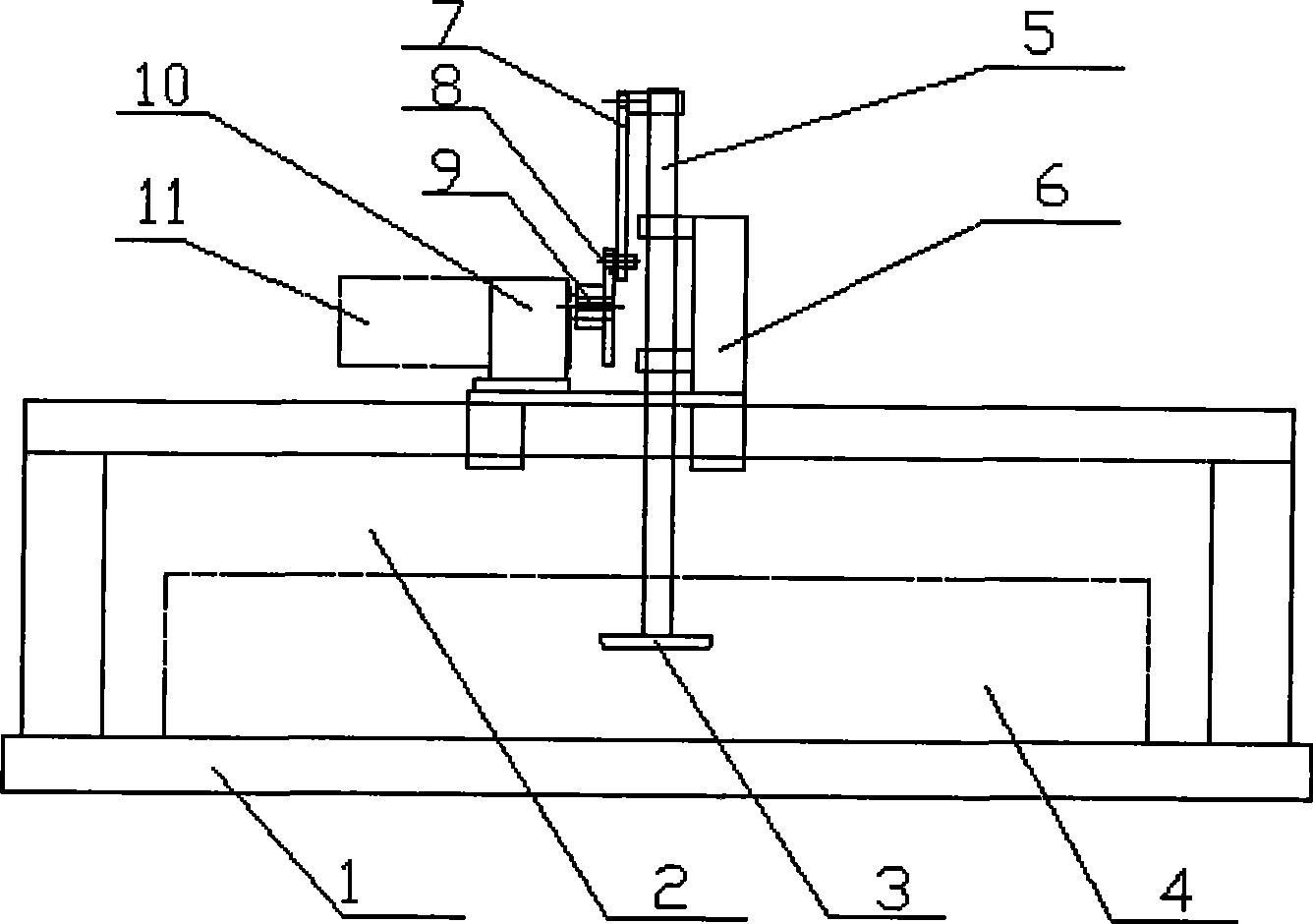

[0008] refer to figure 1 , a mattress durability testing machine, a steel structure beam 2 is erected on the detection platform 1, and a loading device is fixed on the beam. In the loading device, an impact guide rod 5 is connected to the beam 2 by a guide rod support sleeve 6. The guide rod 5 is connected to the connecting rod 7, and the connecting rod 7 is connected to the motor 11 through the eccentric wheel 8, the coupling 9, and the reduction box 10. The loading frequency of the loading head 3 is controlled by adjusting the working speed of the motor 11. After starting the motor 11 , the eccentric wheel 8 runs, drives the impact guide rod 5, and then drives the loading head 3 to reciprocate up and down. After reaching the specified loading times, turn off the motor and perform subsequent detection work. The height of the loading head's up and down movement is determined by the radius of the eccentric wheel.

[0009] Before the test, adjust the impact guide rod to the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com