Multi-axis hydrostatic test device of porous material

A technology of porous materials and test devices, applied in the direction of applying stable tension/pressure to test the strength of materials, to achieve the effect of eliminating pressure effect errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

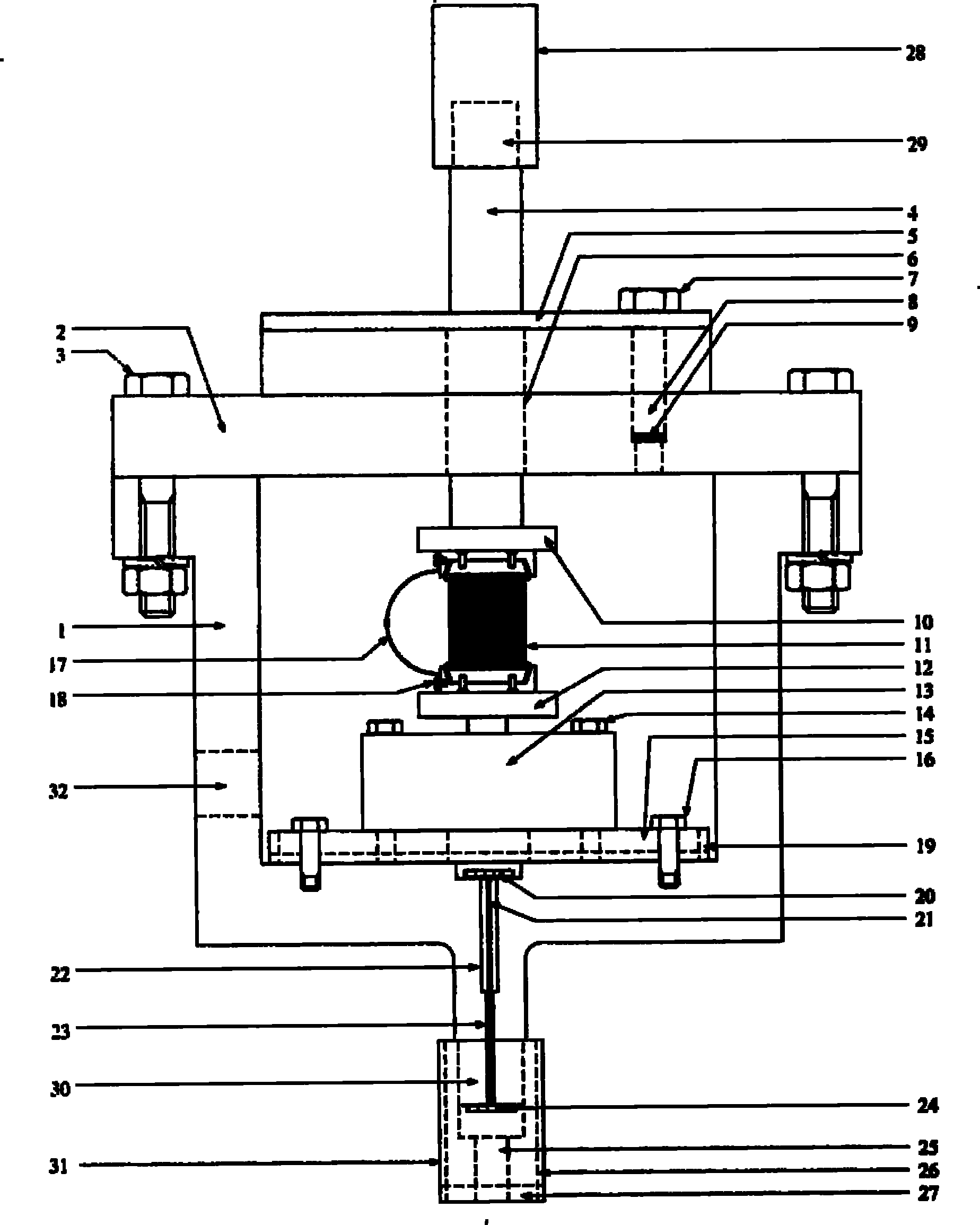

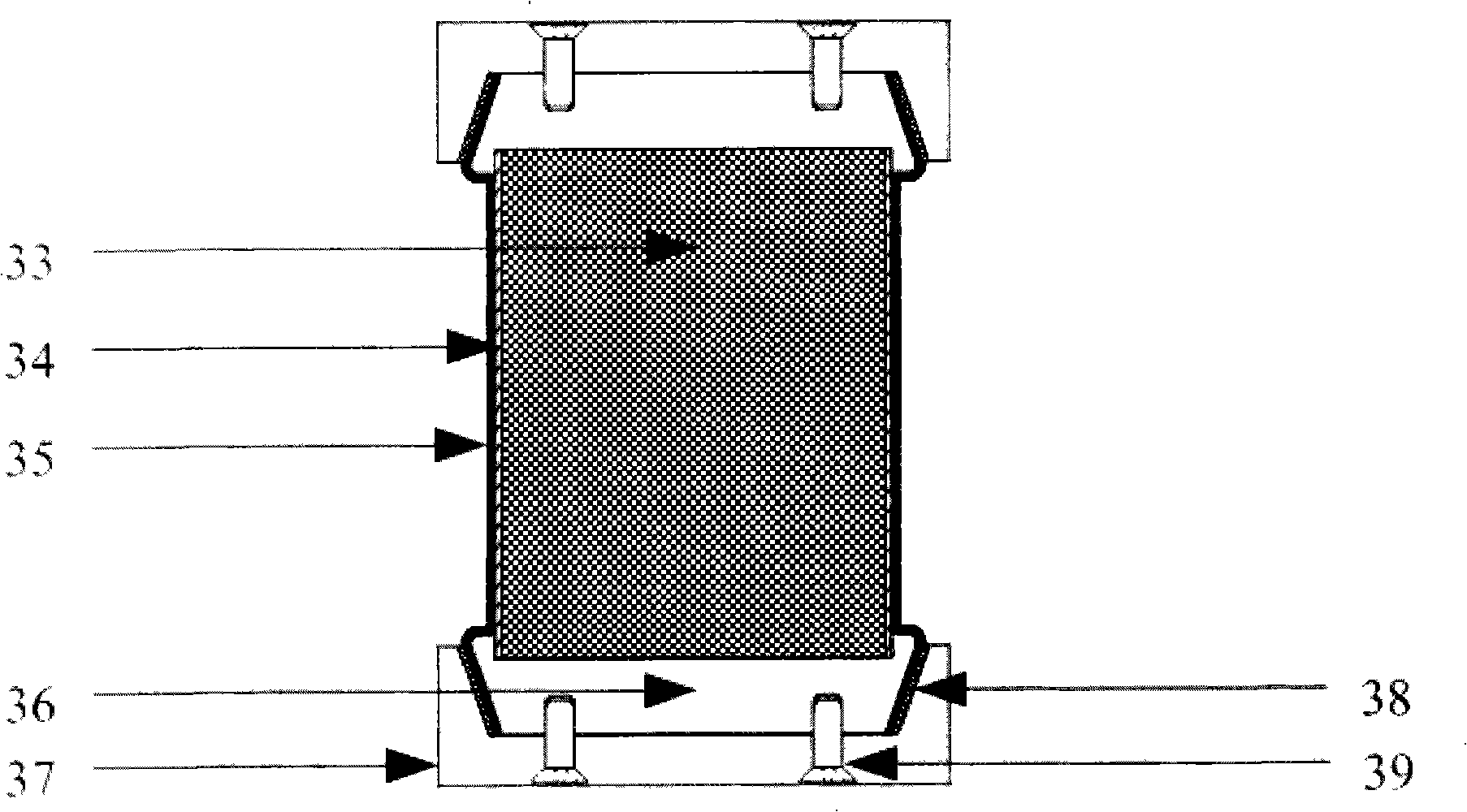

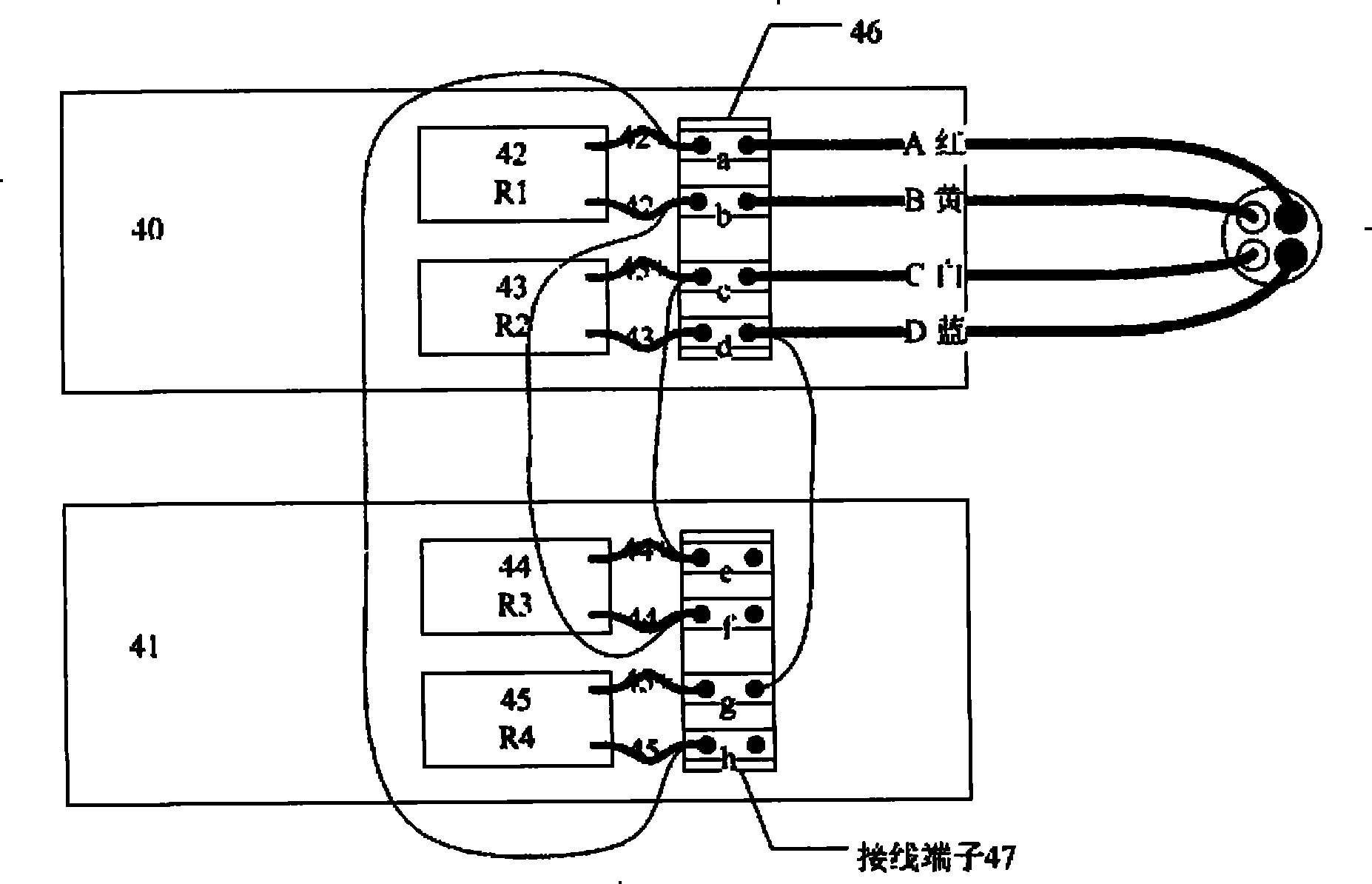

[0012] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0013] refer to figure 1 , the present invention includes a hydraulic chamber 1, an upper cover 2, the hydraulic chamber 1 and the upper cover 2 are connected by bolts 3, the upper part of the upper cover 2 is equipped with a dust cover 5, and the upper cover 2 and the dust cover 5 are provided with an exhaust hole 8 , the exhaust hole 8 is sealed by the bolt 7 and the washer 9, the gap between the axial load piston rod 4 and the upper cover 2 is sealed by the standard assembly 6, and the porous material test piece sealing device 11 is placed on the load cell carrying platform 12 and added Between the force pistons 10, the load sensor 13 is installed on the lower bottom plate 15 with bolts 14, the lower bottom plate 15 is installed at the bottom of the inner wall of the hydraulic chamber 1 with bolts 16, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com