Control method of automatic obstacle-avoiding of robot cleaner

A robot vacuum cleaner and automatic obstacle avoidance technology, applied in two-dimensional position/channel control, installation of electrical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

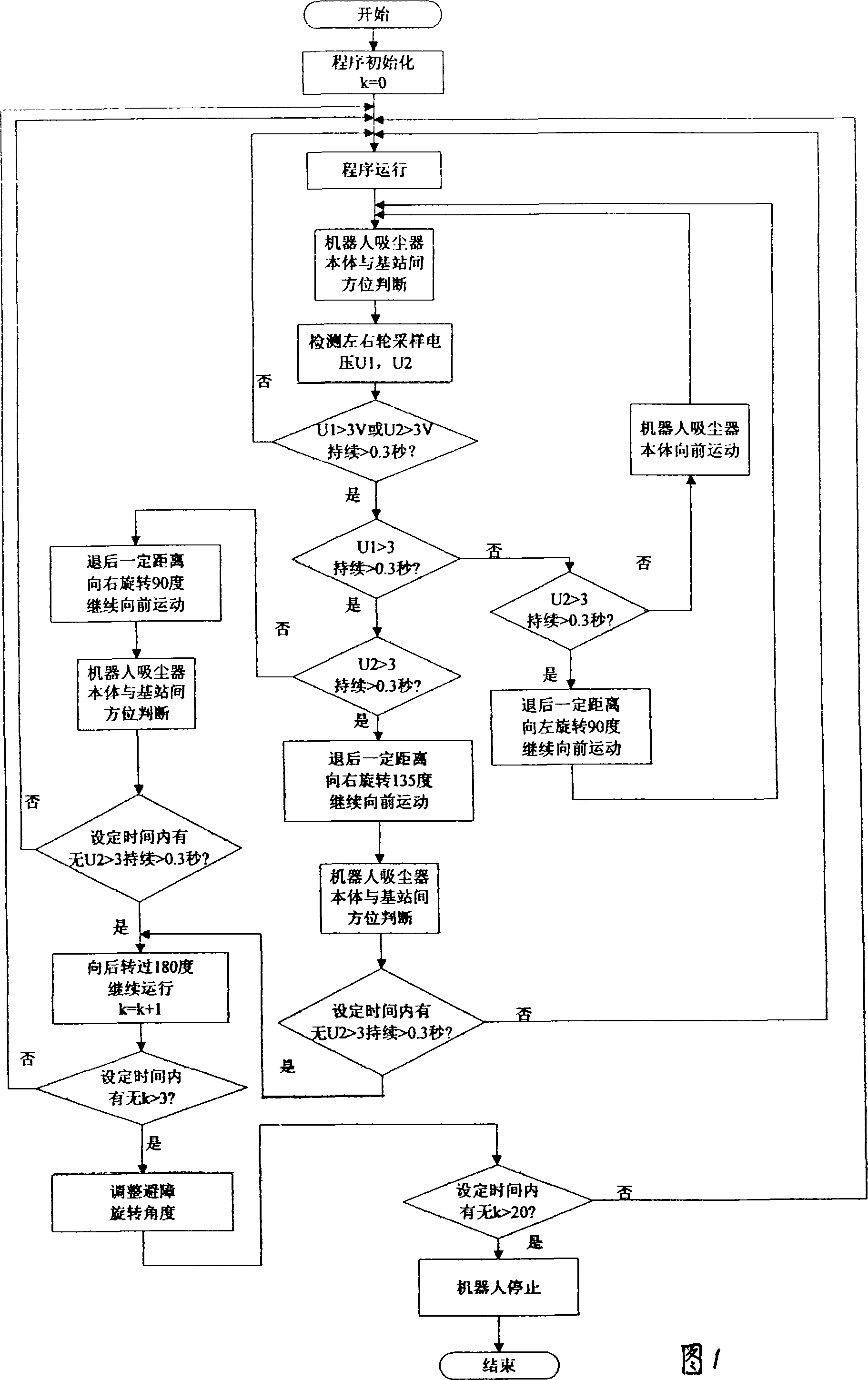

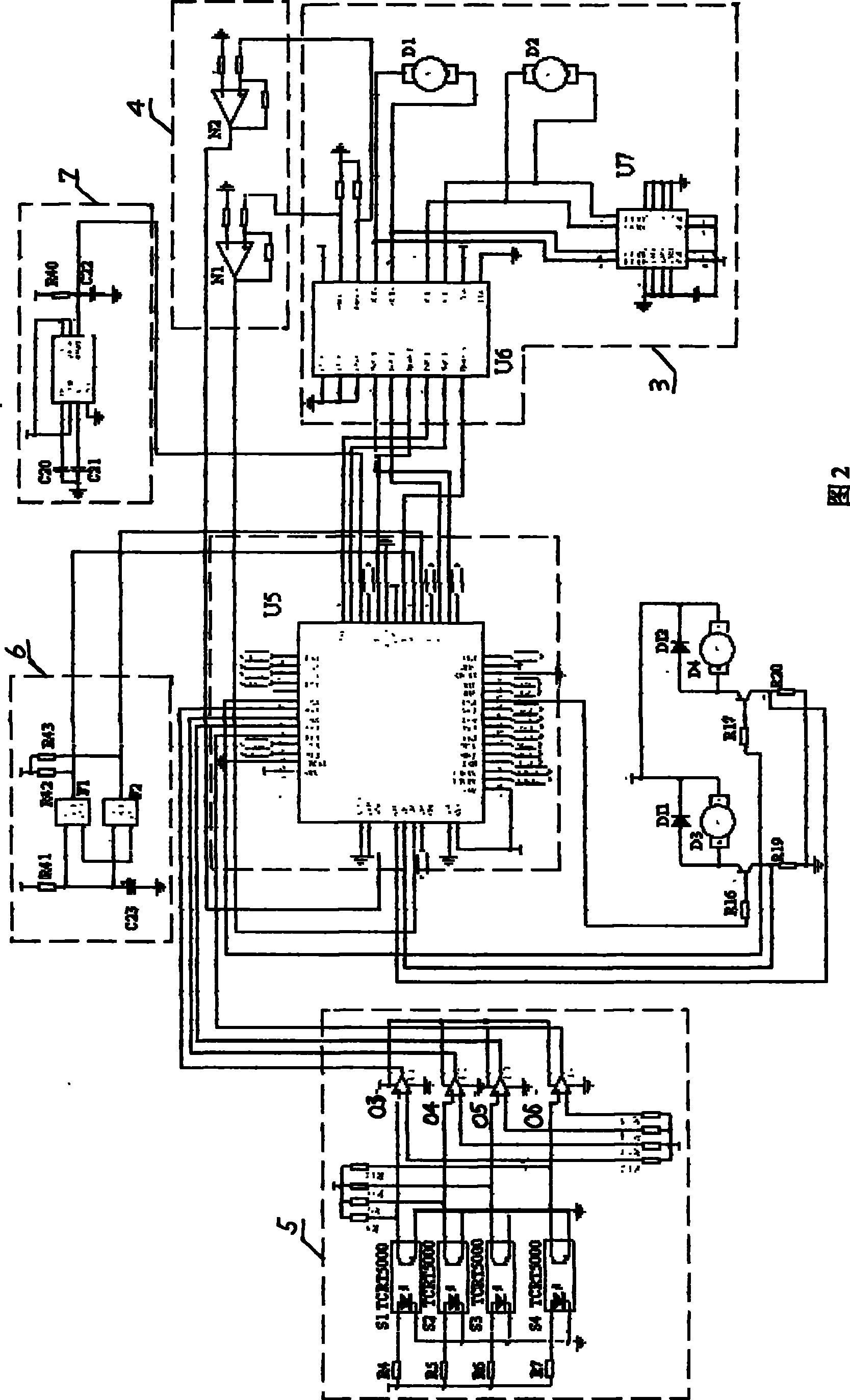

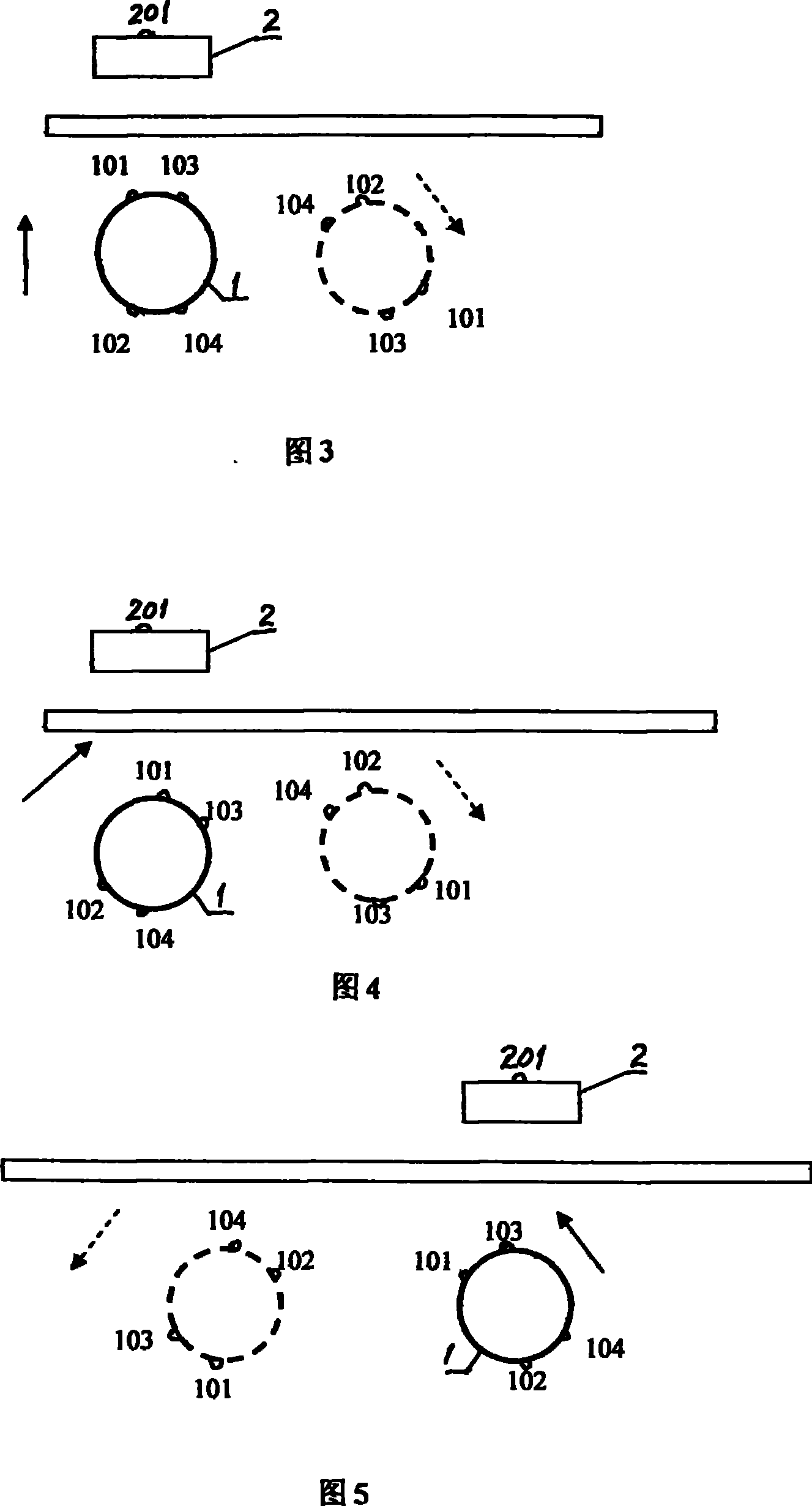

[0020] Referring to Fig. 1 and Fig. 2, a kind of automatic obstacle avoidance control method of the robot vacuum cleaner of the present invention comprises a dust collection body 1, a base station 2 and a control circuit, the dust collection body 1 is provided with left and right wheels, and the dust collection body 1 automatically sucks After dusting, return to the base station 2 for charging and vacuuming. The top of the base station 2 is provided with an infrared transmitter 201, which continuously emits infrared waves to the vacuum body 1. Four infrared receivers 101, 102, 103 are arranged on the upper part of the vacuum body 1. , 104, receiving the infrared communication signal sent from the base station 2.

[0021] The control circuit includes a single-chip microcomputer U5, a driving circuit 3, a current feedback circuit 4, an anti-falling circuit 5, an infrared receiving circuit 6, and a voltage monitoring circuit 7. The driving circuit 3 is connected with the single-ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com