Method of fabricating rare-earth sintered magnet and method of fabricating rare-earth bonded magnet

A technology of sintered magnets and bonded magnets, which is applied to magnetic objects, magnetic materials, transportation and packaging, etc., can solve the problems of non-mass production, and achieve the prevention of evaporation, oxidation and excessive nitriding suppression, and excellent magnetic properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

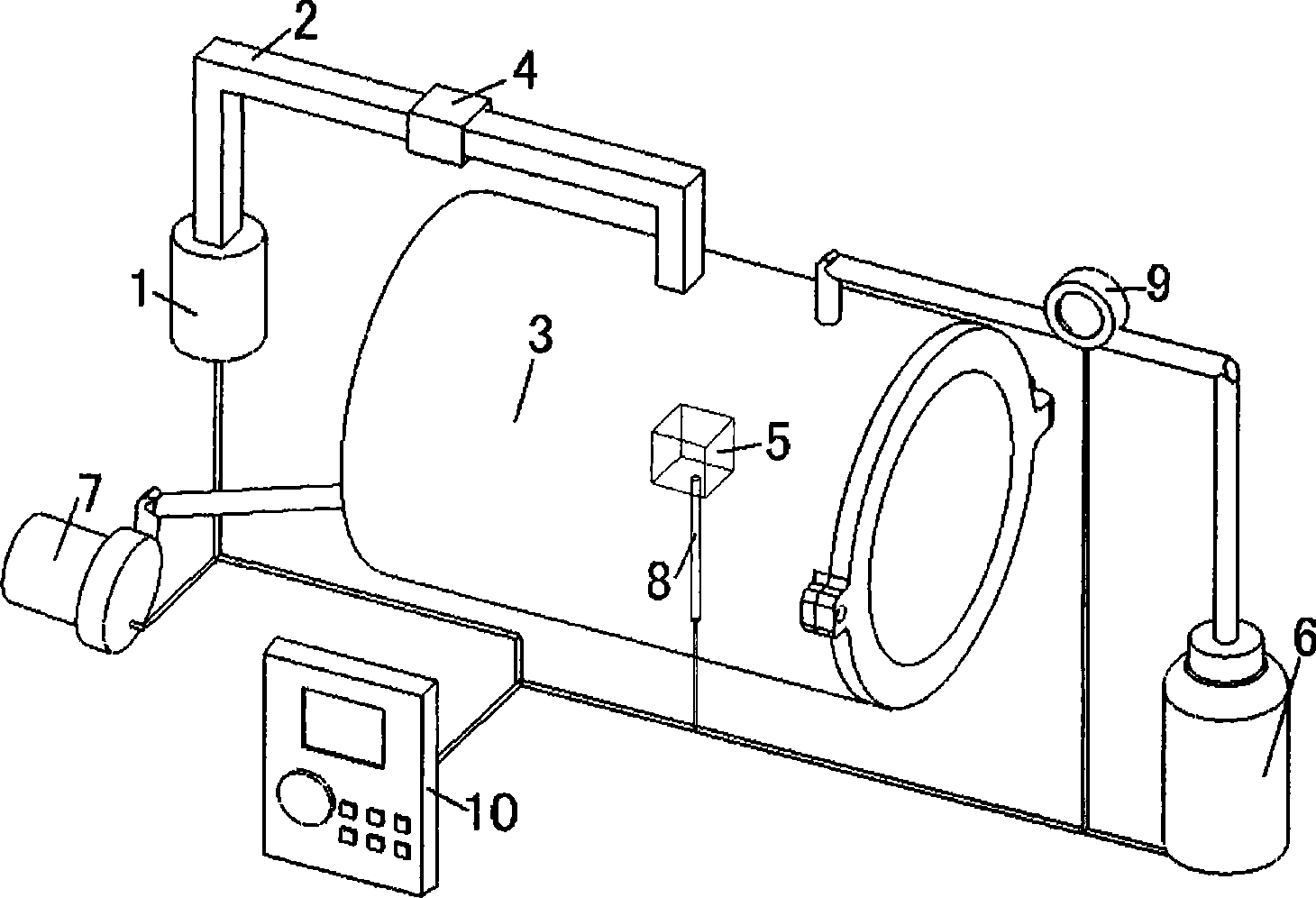

[0027] figure 1 is a schematic perspective view of an apparatus for implementing a method of manufacturing a magnet according to an embodiment of the present invention. The device includes a microwave generating tube 1 for generating microwaves. The tube 1 is connected to an applicator 3 via a waveguide 2 . The microwave emitted by the microwave generating tube 1 is transmitted to the applicator 3 through the waveguide 2 . An isolator 4 is installed in the waveguide 2 . The isolator 4 transmits the microwaves in the waveguide 2 only towards the applicator 3 and absorbs the microwaves transmitted in the opposite direction.

[0028] Sample 5 was placed in applicator 3 and irradiated with microwaves. The applicator 3 is a closed metal container, and is designed to prevent leakage of microwaves to the outside. A gas supply source 6 for introducing an inert gas such as nitrogen is connected to the applicator 3 . In addition, a pump 7 for evacuating the inner atmosphere is con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com