Negative-pressure operation type reverse osmosis filter membrane system

A technology of reverse osmosis and membrane filtration, applied in the direction of reverse osmosis, semi-permeable membrane separation, membrane technology, etc., can solve the problems of low operating pressure, poor watertight effect of flat filter units, and easy water leakage, etc. Conducive to the effect of quick cleaning and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

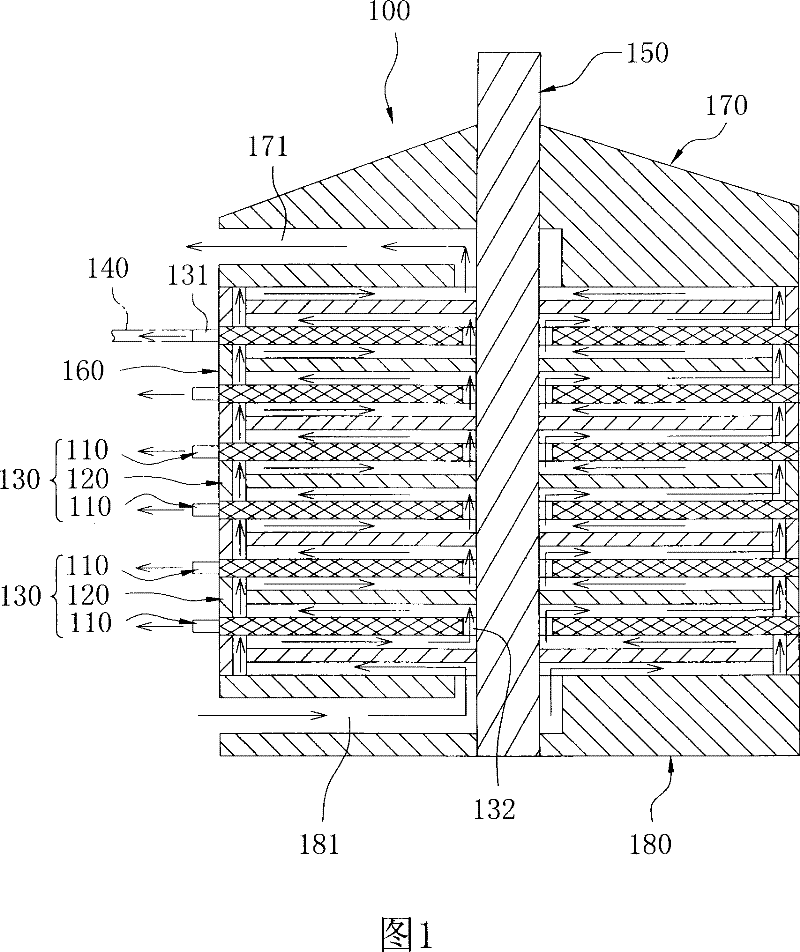

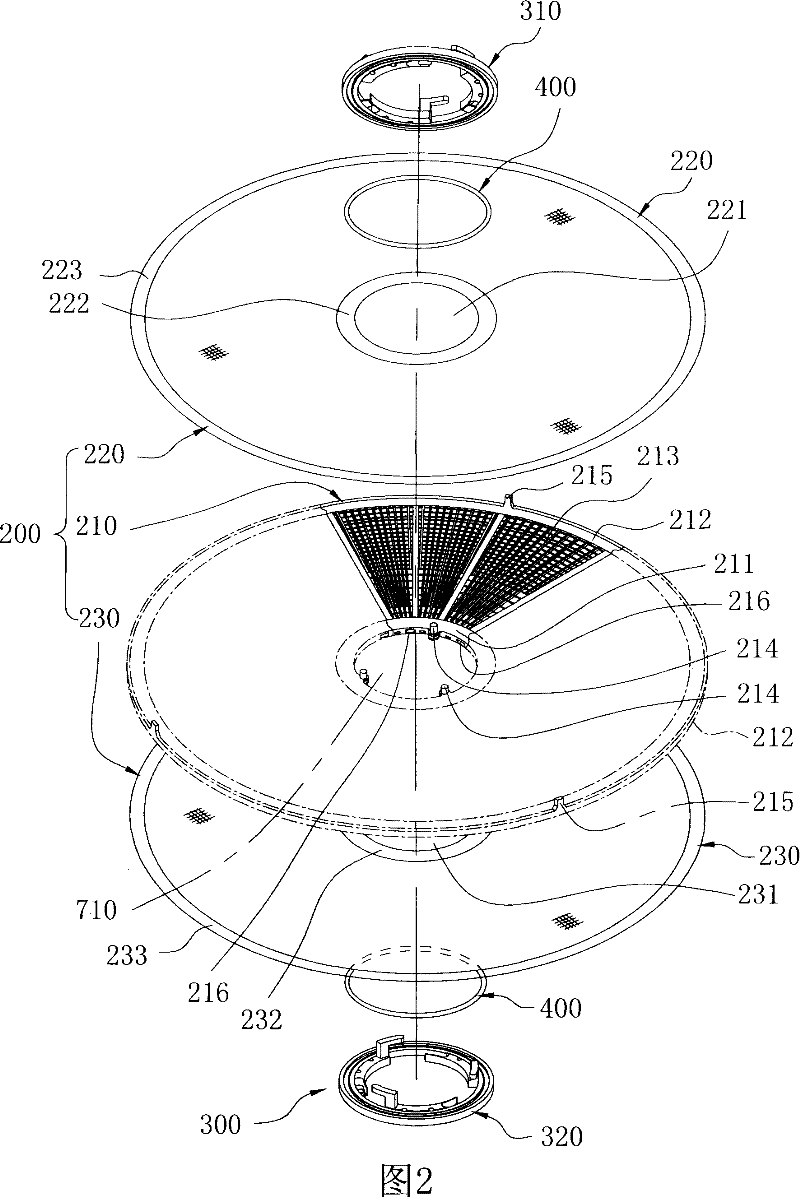

[0058] refer to figure 2 and Figure 8 , an embodiment of the negative pressure operated reverse osmosis membrane system of the present invention, comprising a plurality of reverse osmosis membrane units 200, a plurality of fastening units 300, a plurality of watertight units 400, a top cover 500 and a bottom cover 600 .

[0059] refer to figure 2 and Figure 4 , each of a plurality of reverse osmosis membrane units 200 respectively has a membrane support plate 210 , a first membrane 220 and a second membrane 230 in a sandwich structure. The above three can define a chamber 700 for water dialysis, and the above three also have a water production hole 710 extending in the axial direction and communicating with the chamber 700 .

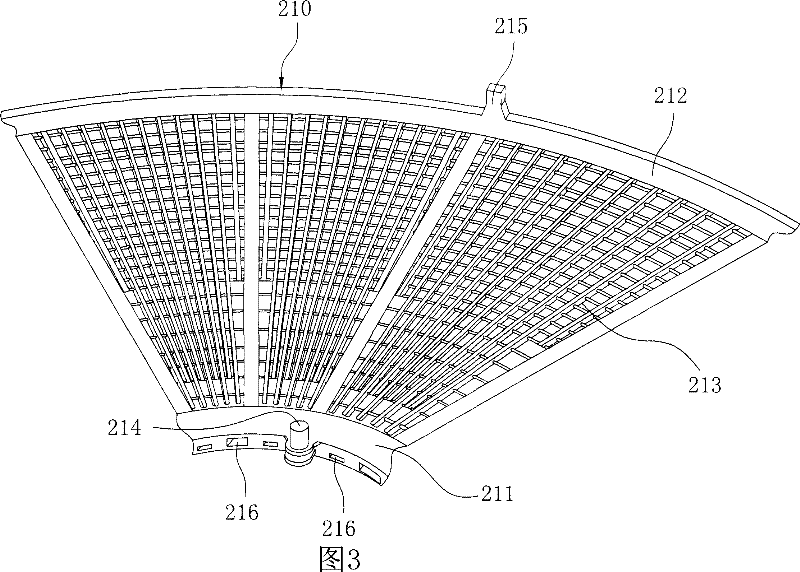

[0060] refer to figure 2 , image 3 and Figure 4 , the membrane support plate 210 has an inner ring 211, an outer ring 212 coaxial with the inner ring 211, a clamping net 213 connected between the inner and outer rings 211, 212, a plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com