Hand-held electric cleaning device

A cleaning machine, hand-held technology, applied in the field of cleaning machines, can solve the problems of needing to replace nozzles, inconvenient shutdown, complex structure, etc., and achieve the effects of wide application, reduced floating weight, and reduced cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

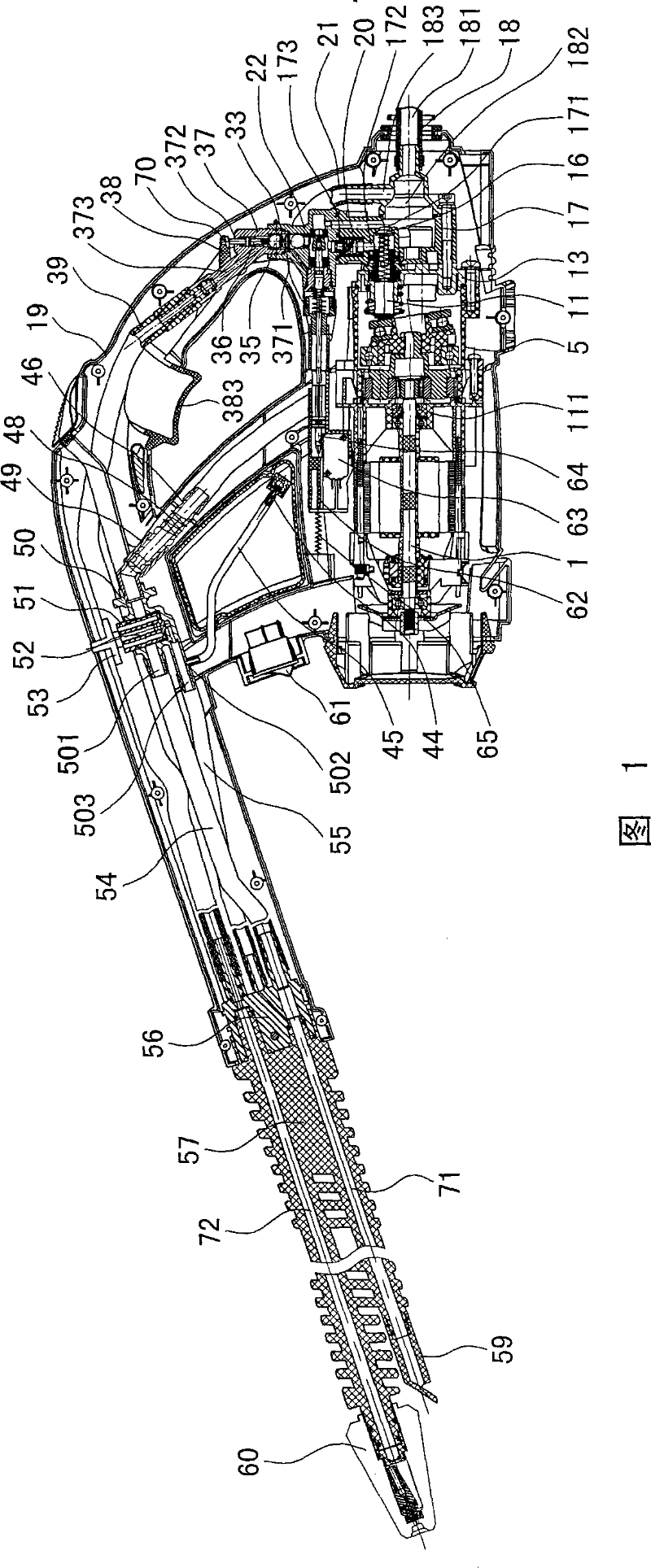

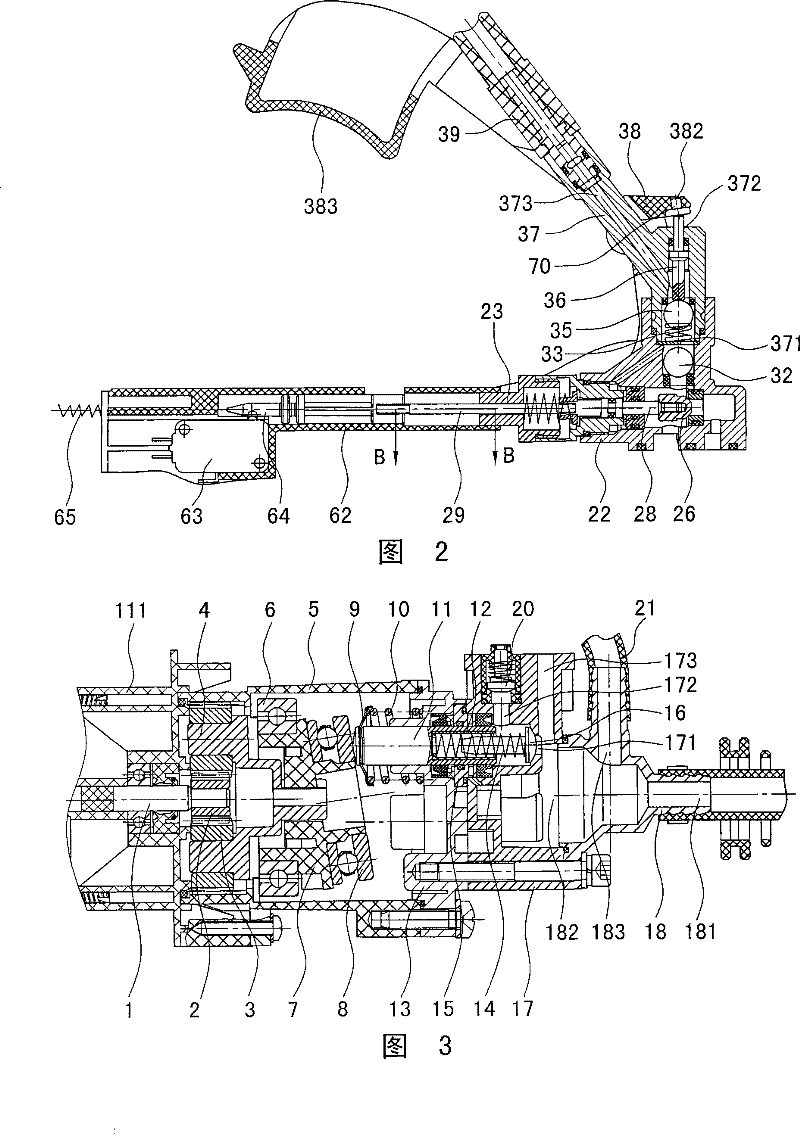

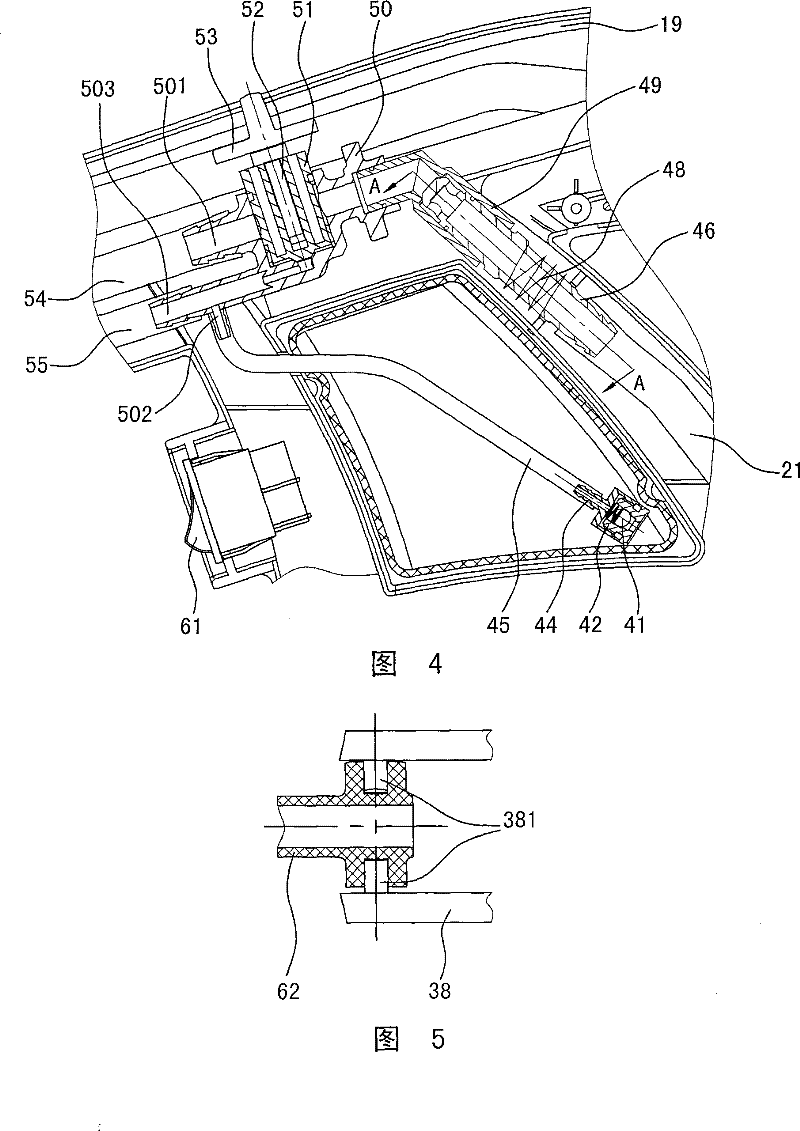

[0015] The invention discloses a hand-held electric cleaning machine, which includes a motor, a high-pressure pump, a spray gun and a control switch. The motor drives the high-pressure pump through a reduction mechanism, such as figure 1 As shown, the motor casing 111 is connected to the pump body 13 through the connecting seat 5, and the end of the motor shaft 1 extends into the connecting seat 5. The center wheel 2 is installed at the end of the motor shaft 1, and two planetary wheels 3 are installed outside the center wheel. The internal gears made in the connecting seat 5 are meshed, one end of the planet carrier 4 is installed in the inner hole of the second planetary wheel, and the other end is installed in the special-shaped hole of the bearing seat 7, and the radial ball bearing 6 is installed at one end of the bearing seat, and the other end is installed. There is a thrust ball bearing 8; the other end of the connecting seat is equipped with a pump body 13; the high-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com