Aluminum alloy ingot casting area water cooling device

A technology of aluminum alloy ingot casting and water cooling device, which is applied in the field of water cooling device in the ingot region, can solve the problems of poor forming, easy cracking, and large internal stress of hard aluminum alloy, so as to meet the needs of hard aluminum alloy casting, easy automatic control, Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

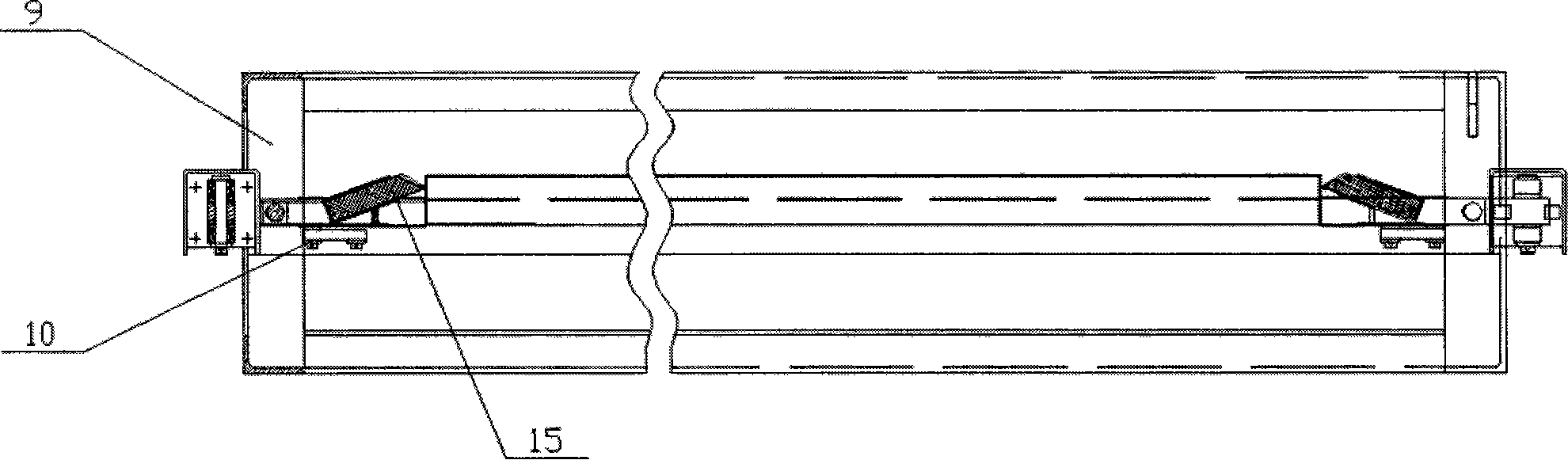

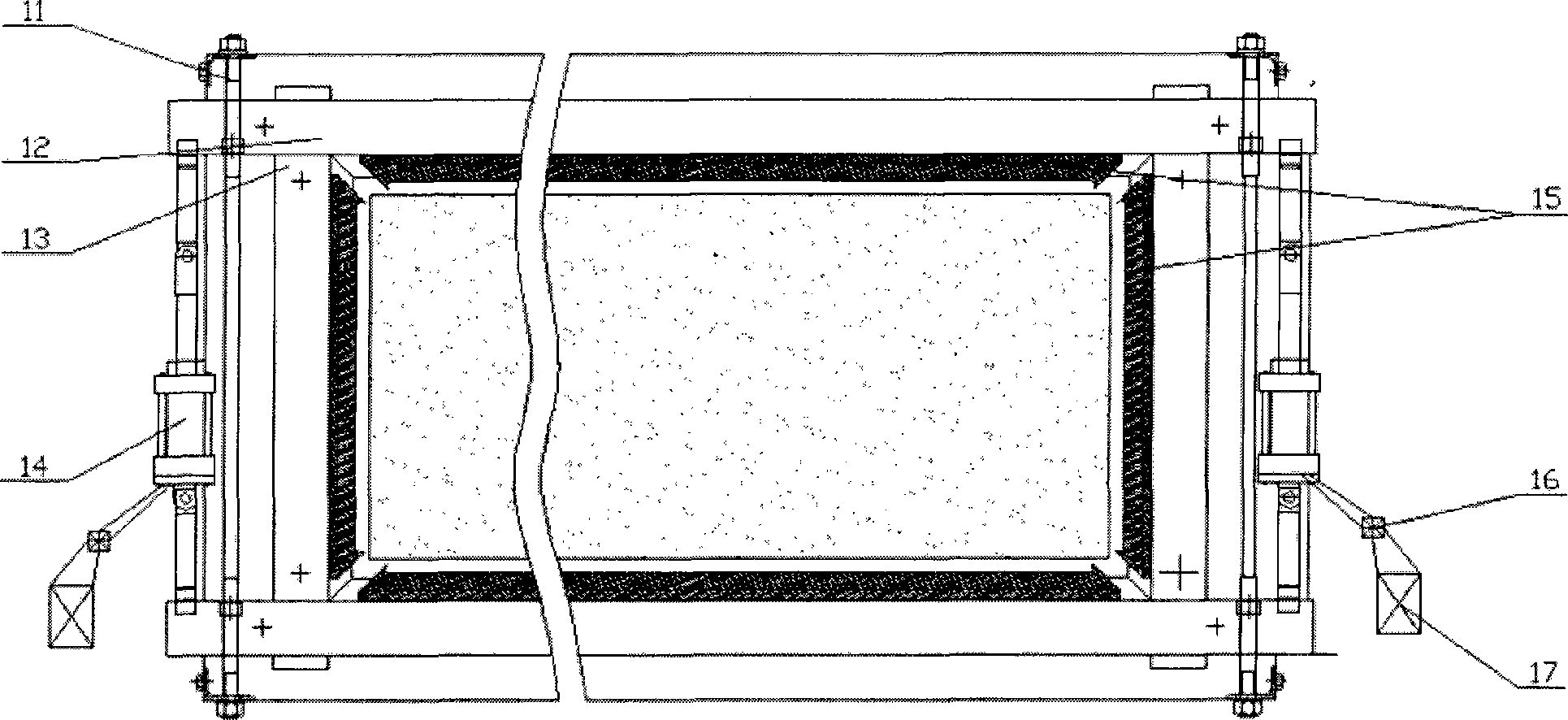

[0023] Such as Figure 2-4 As shown, the water-cooling device in the aluminum alloy ingot area specifically includes a bracket 9, a main splint 12, a secondary splint 13, a connecting rod 10, a cylinder 14, and a wiper blade 15. The bracket 9 plays a role in supporting the entire device. A plurality of positioning holes or guide grooves are provided in the height direction, and support rods 11 are worn in the positioning holes or guide grooves, and two main splints 12 are set on the support rods 11, one main splint at the front and the rear, and two main splints 12 Cylinder 14 is arranged between, and each main splint 12 connects a secondary splint 13 respectively by connecting rod 10, namely left and right each secondary splint, wiper blade 15 is all installed on the inner wall of each main splint 12 and secondary splint 13; Main splint 12 and secondary splint 13 and wiper blade 15 are all in the plane of same height.

[0024] Specifically, there are multiple positioning hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com