Cathode carbon block group preheating device

The technology of cathode carbon block and preheating device is applied in the field of preheating device, which can solve the problems of impact of cathode carbon block group, large investment, high heating energy consumption, low external condition requirements, casting requirements, and good temperature uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

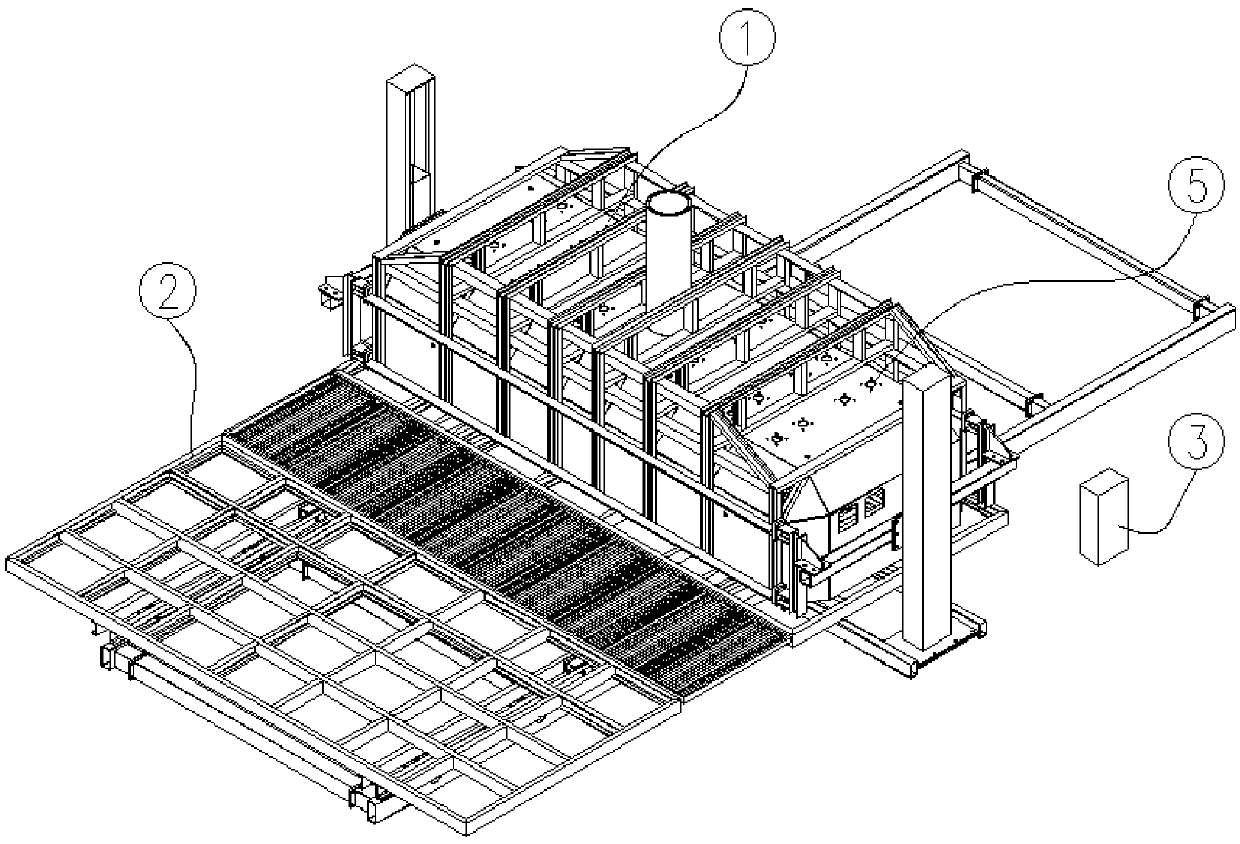

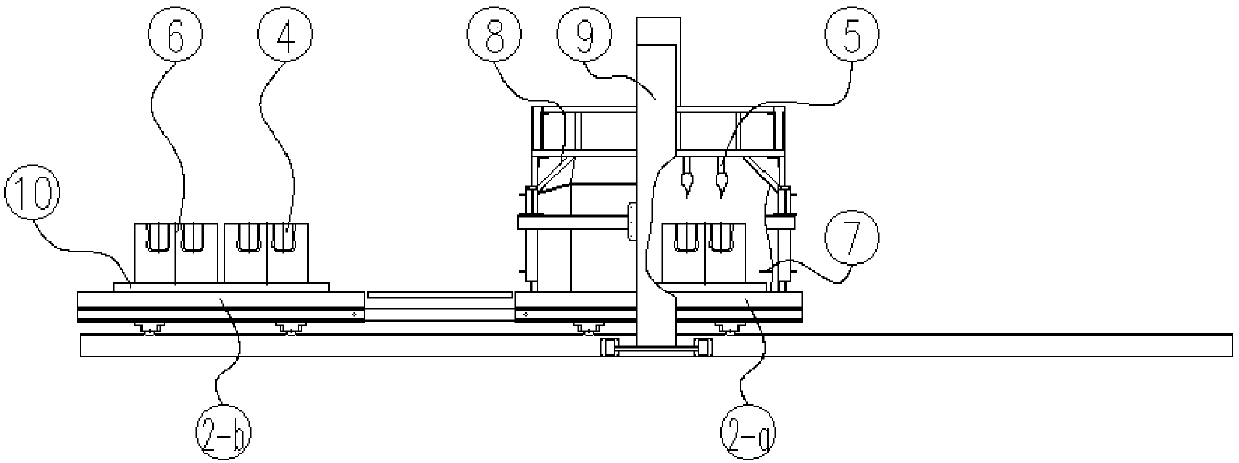

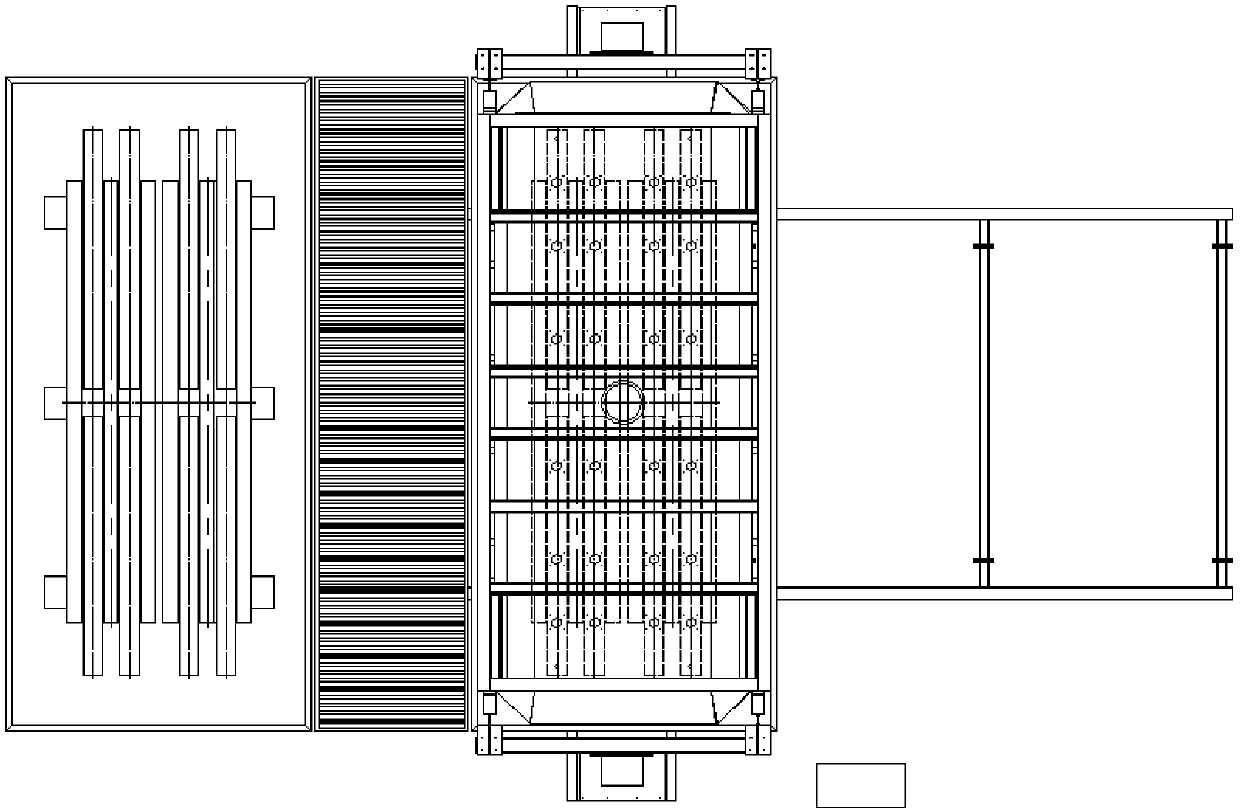

[0034] Such as Figure 1-Figure 4 As shown, the cathode carbon block group preheating device in this embodiment mainly includes: a heating furnace body 1, a base 2 and a control system 3, etc., and the specific structure is as follows:

[0035] The heating furnace body 1 is arranged on the base 2, and the heating nozzle 5 is arranged on the upper part of the heating furnace body 1 corresponding to the vertical projection area of the cathode steel rod 4, and the cathode steel rod 4 is directly heated through the heating nozzle 5, and the cathode carbon block 6 is then Indirect heating is performed through heat exchange with the cathode steel rod 4 and the surrounding hot air, and the control system 3 controls the heating process of the cathode carbon block group by controlling the heat generated by the heating nozzle 5 .

[0036] The position of the heating nozzle 5 along the length direction of the cathode carbon block group is adjustable. A temperature measuring device 7 is...

Embodiment 2

[0041] In this embodiment, the fuel used by the cathode carbon block group preheating device is heavy oil, and the others are the same as in Embodiment 1.

Embodiment 3

[0043] In this embodiment, the cathode carbon block group preheating device heats 8 groups of cathode carbon block groups each time, and the others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com