Soft-plate retention device

A technology for holding devices and soft boards, which is applied in the direction of workpiece holding devices, auxiliary devices, laser welding equipment, etc., and can solve the problems of poor air tightness of holding devices, different drilling diameters, uneven board surfaces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The flexible board holding device of the technical solution will be described in detail below in conjunction with the accompanying drawings.

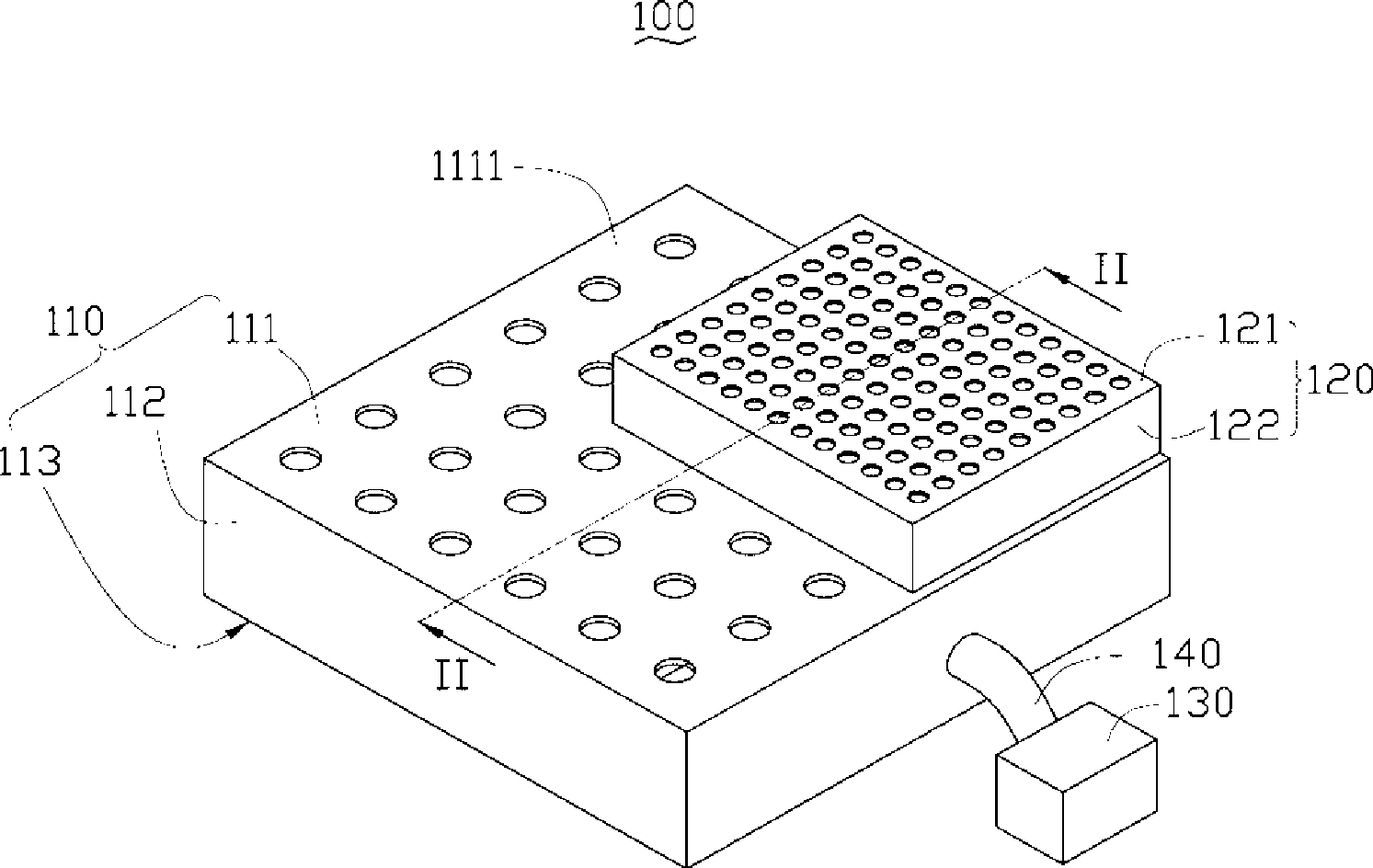

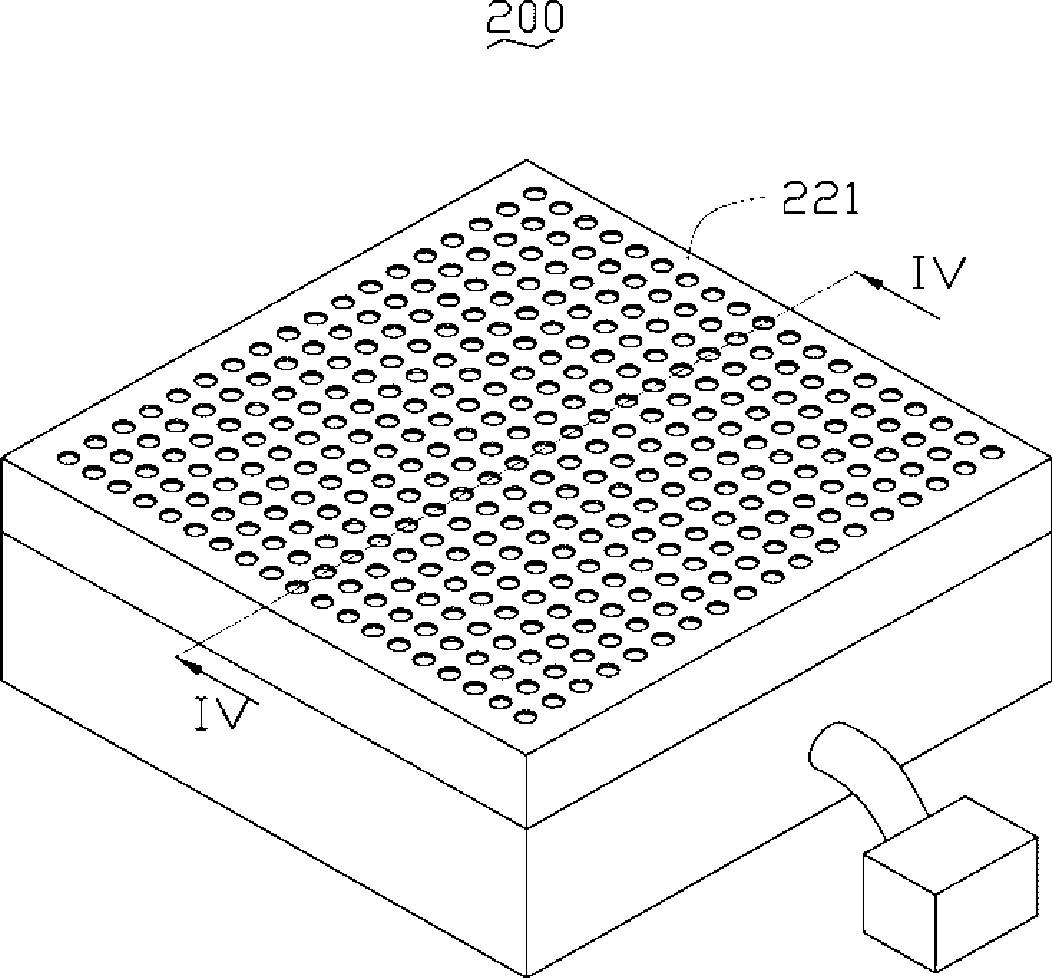

[0014] Please also refer to figure 1 and figure 2 The flexible board holding device 100 provided in the first embodiment of the technical solution includes a first carrying device 110 , a second carrying device 120 and an air suction device 130 .

[0015] The first carrying device 110 includes a first carrying portion 111 , a first side wall 112 and a first bottom wall 113 .

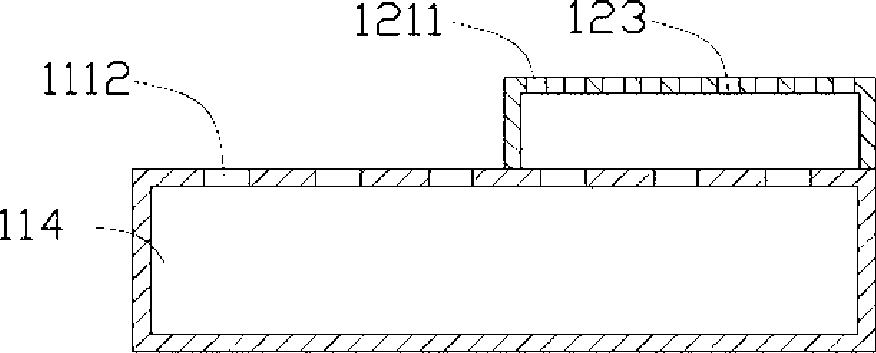

[0016] The first bearing portion 111 is opposite to and parallel to the first bottom wall 113 . The first side wall 112 is disposed between the first bearing portion 111 and the first bottom wall 113 , and forms a rectangular parallelepiped structure together with the first bearing portion 111 and the first bottom wall 113 , thereby forming a first cavity 114 . In order to ensure airtightness, preferably, the first bearing portion 111 , the first side w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com