Alarming device for material cut-off of conveyer belt

A technology for alarm devices and conveyor belts, which is applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve problems such as application field restrictions, and achieve low maintenance costs, obvious effects, and fast response effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation of the device for measuring the height of the blanking pile of the present invention is provided below, and an example is provided, but the present invention is not limited to the provided example.

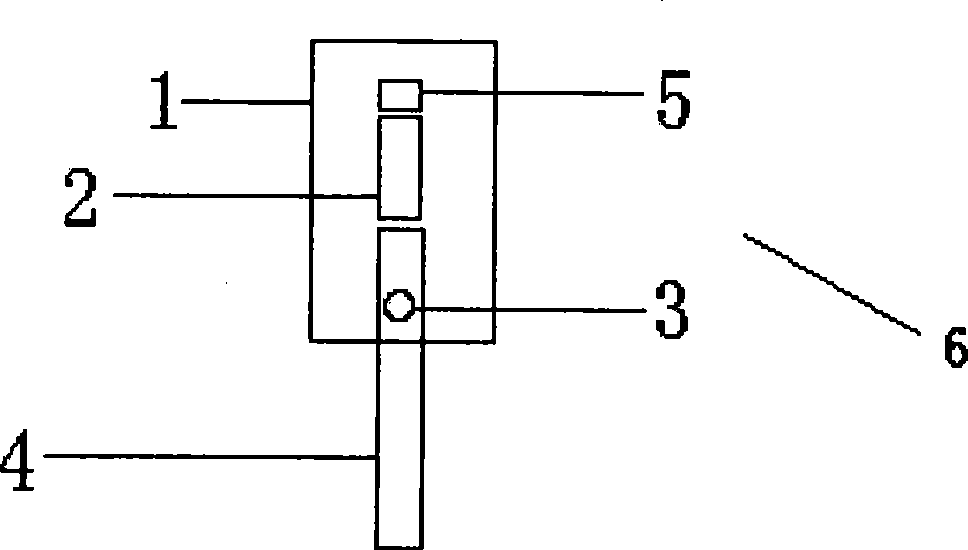

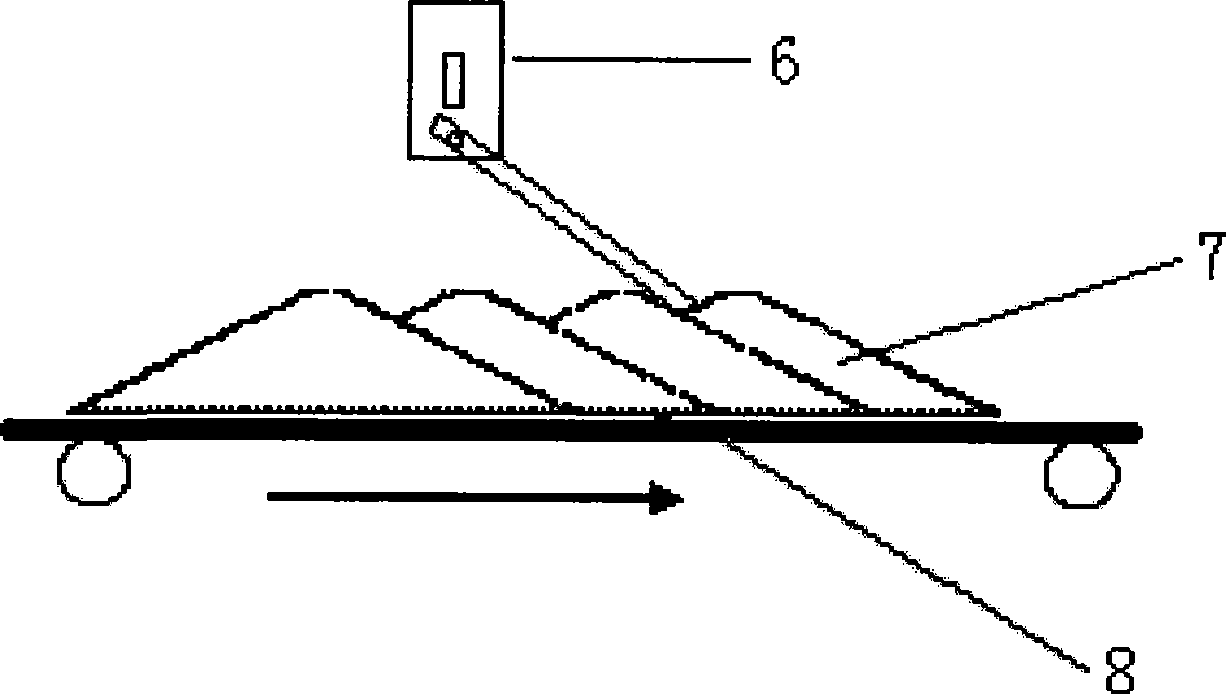

[0022] See attached figure 1 and 2 . The device 6 includes a protective fixing device 1 , a swing angle detection device 2 , a swing shaft 3 , a pendulum 4 and a signal output device 5 . The free swinging device adopts a fan-shaped steel sheet, and the plane of the steel sheet is aligned with the flow direction of the material 7 to increase the sensitivity of perception, and the magnetic steel is fixed on the upper end of the pendulum; the swing angle detection device uses a reed switch; the signal output is connected to the reed switch electrical contacts. When there is enough material flow on the conveyor belt 8, the material drives the fan-shaped steel sheet to lift an angle, so that the magnetic steel on the pendulum is far away from the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com