Riser pipe construction technique of artificial island well drilling

The technology of a riser and a construction process is applied in the field of preliminary civil engineering construction of a beach oil drilling project, and can solve the problems of poor construction quality, poor construction effect of a drilling riser, and a low safety factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

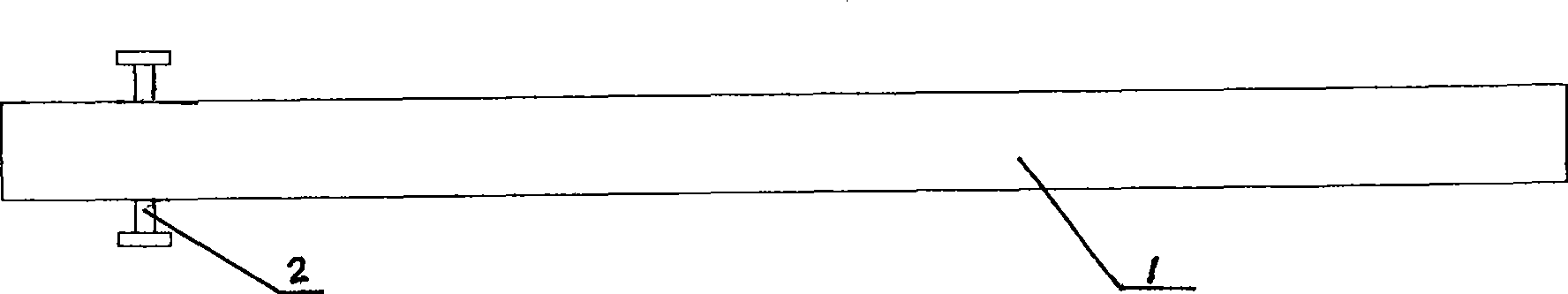

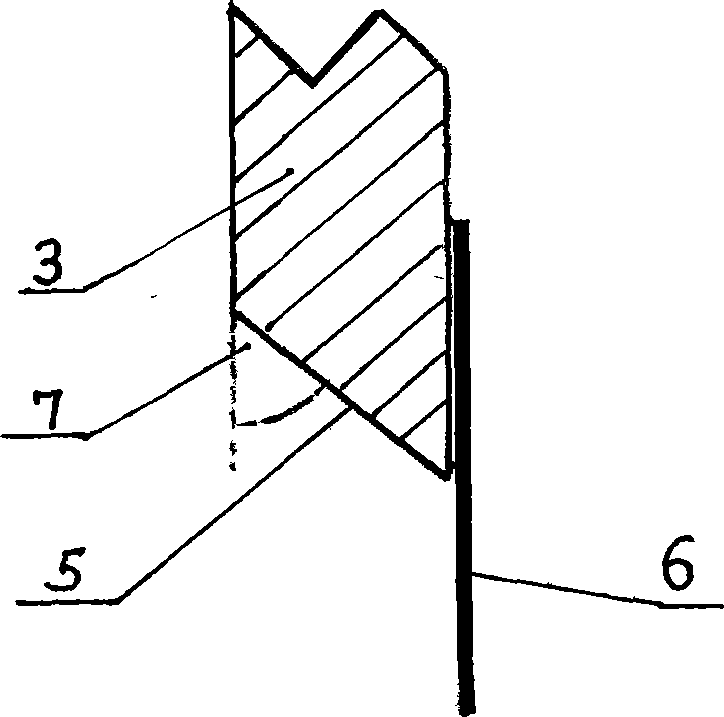

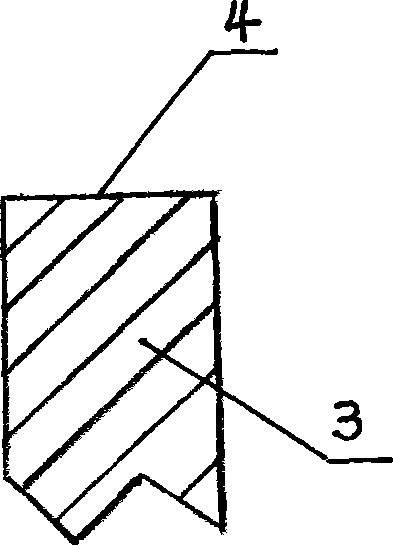

[0037] The process method of the present invention will be further described below in conjunction with the accompanying drawings and embodiments. It is known that a certain artificial island needs to implement on-site construction of a water-resisting conduit. Taking the Φ600mm×25mm×12000mm type water-resisting conduit commonly constructed as an example, the length of the wellhead groove is 30 meters, and the distance between each wellhead is 3.2 meters. It can be seen from the above that the diameter of the riser is D=60cm, the wall thickness is 25mm, and the length is 12m.

[0038] The first step Drilling riser prefabrication

[0039] Q235B steel plate is used, and it is processed into a cylinder with a diameter of 600mm by a plate rolling machine. A 12-meter-long water-resistance conduit is usually welded by 5 cylinders. The welding material of the model E4315 and the H08A welding wire are used. The weld must be For ultrasonic testing, the quality of the welds must meet th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com