Thrust roller for preventing machine from deflecting by auto-adapting position of wheel and diameter of tyres for roller test stand

A technology of automatic adaptation and test bench, which is applied in the direction of vehicle testing, machine/structural component testing, instruments, etc. It can solve problems such as inaccurate positioning, long installation time, and long time-consuming, so as to achieve no friction loss, installation and debugging and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

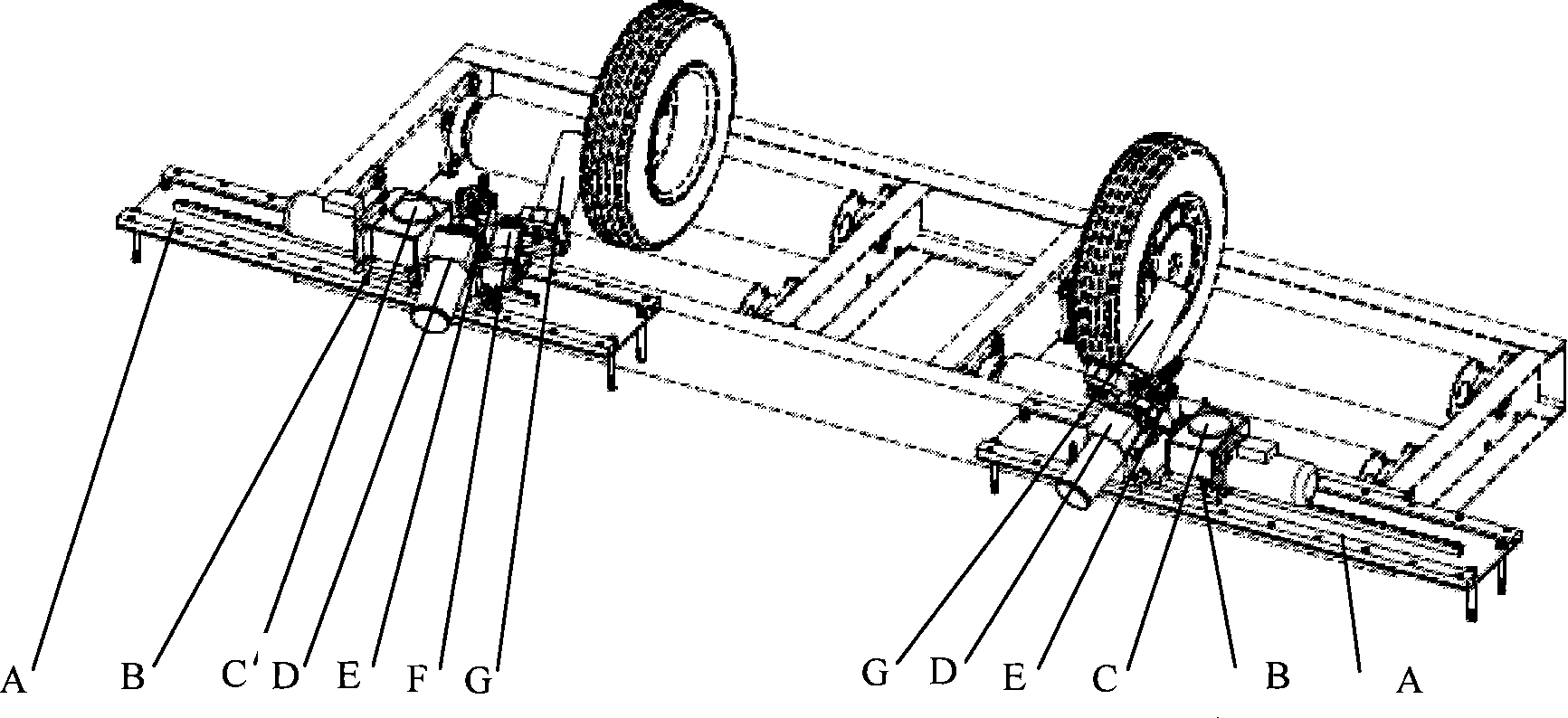

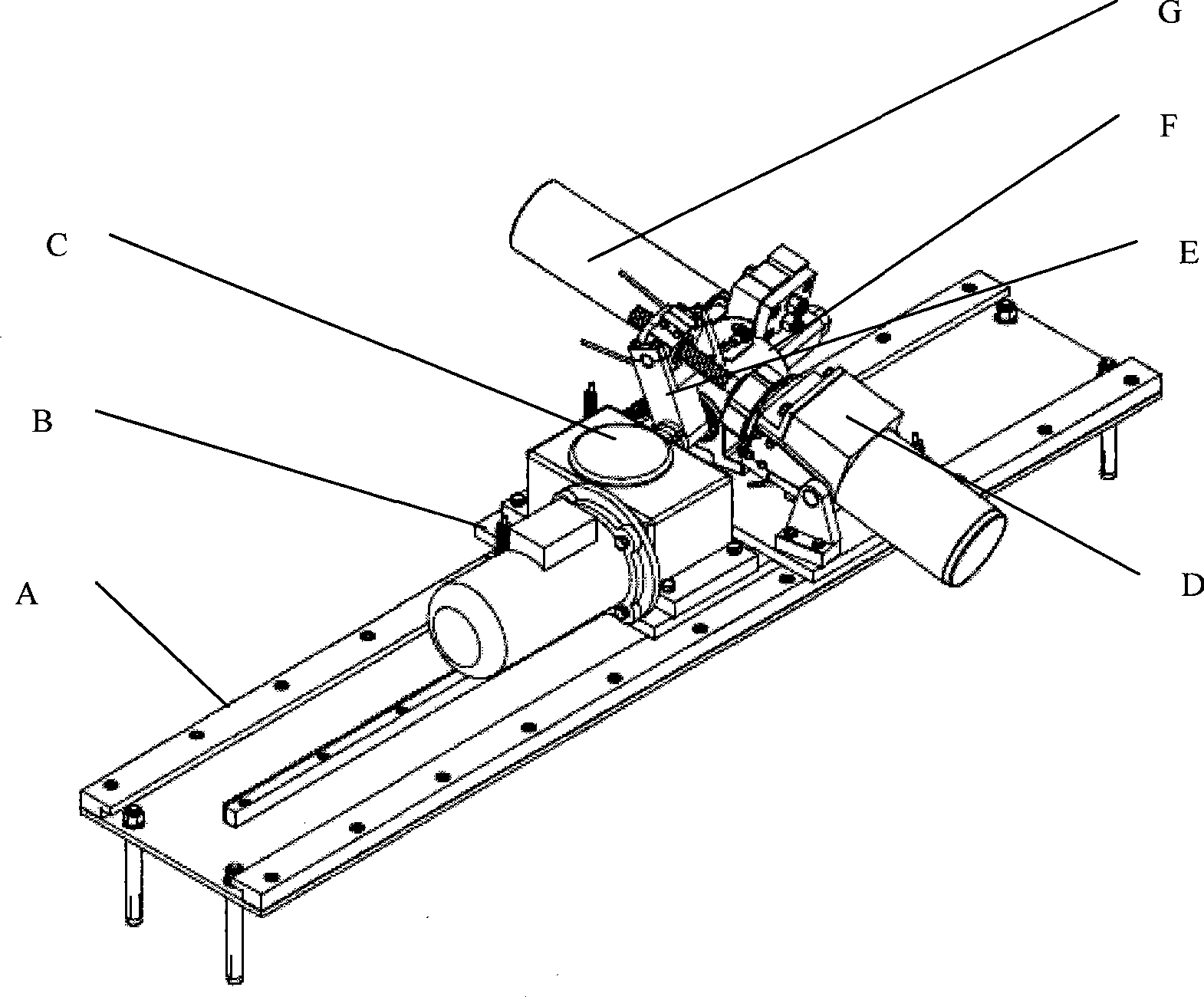

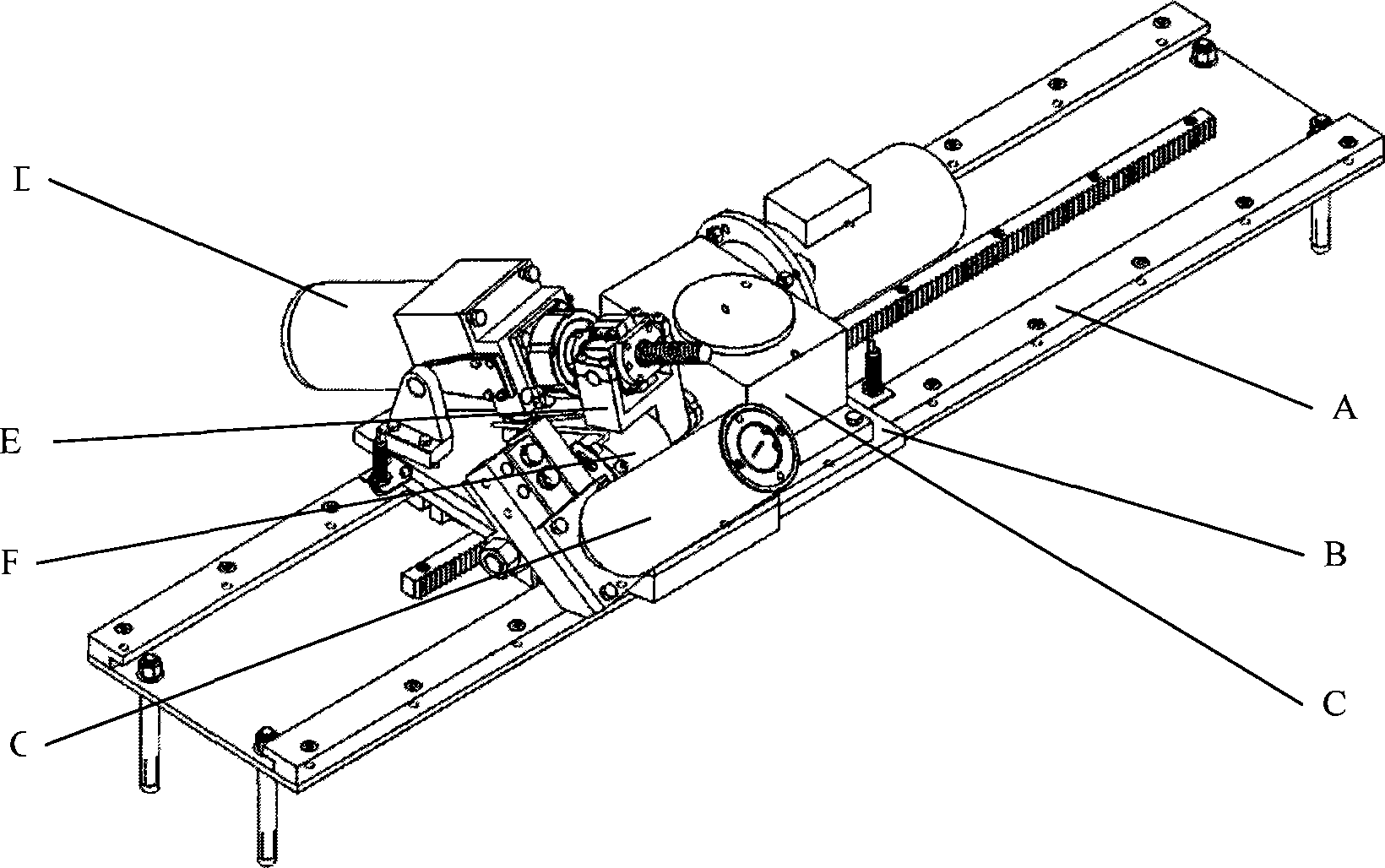

[0042] The specific content and working principle of the present invention will be further described below according to the embodiments shown in the accompanying drawings.

[0043] The roller test bench is composed of two benches that are completely symmetrical on the left and right. Each stand includes: ground guide rail part A: rack 1, guide rail bar 2, ground guide rail bottom plate 3, expansion bolt 4, slide plate part B: slide plate 5, turntable plate guide rail bar 6, slide plate leg 7, auxiliary slide plate leg 8, Outer limit proximity switch 59, outer limit proximity switch support plate 60, spring fixed pull plate 61, tension spring 62, baffle plate 63, motor worm gear reducer part C: motor 9, worm gear reducer 10, gear 11, adjustment Speed motor and ball screw part D: ball screw 12, round nut 13, thrust pad 14, bearing outer ring thrust nut 15, screw bearing jacket 16, motor screw force transmission seat 17, motor reducer bracket 18 , speed regulating motor 19, mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com