Field emission type electronic source and manufacturing method thereof

An electron source, field emission technology, applied in cathode ray tube/electron beam tube, electrode system manufacturing, discharge tube/lamp manufacturing, etc. It is difficult to solve problems such as electron source, so as to achieve the effect of increasing the voltage and increasing the insulation distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution will be further described in detail below in conjunction with the accompanying drawings.

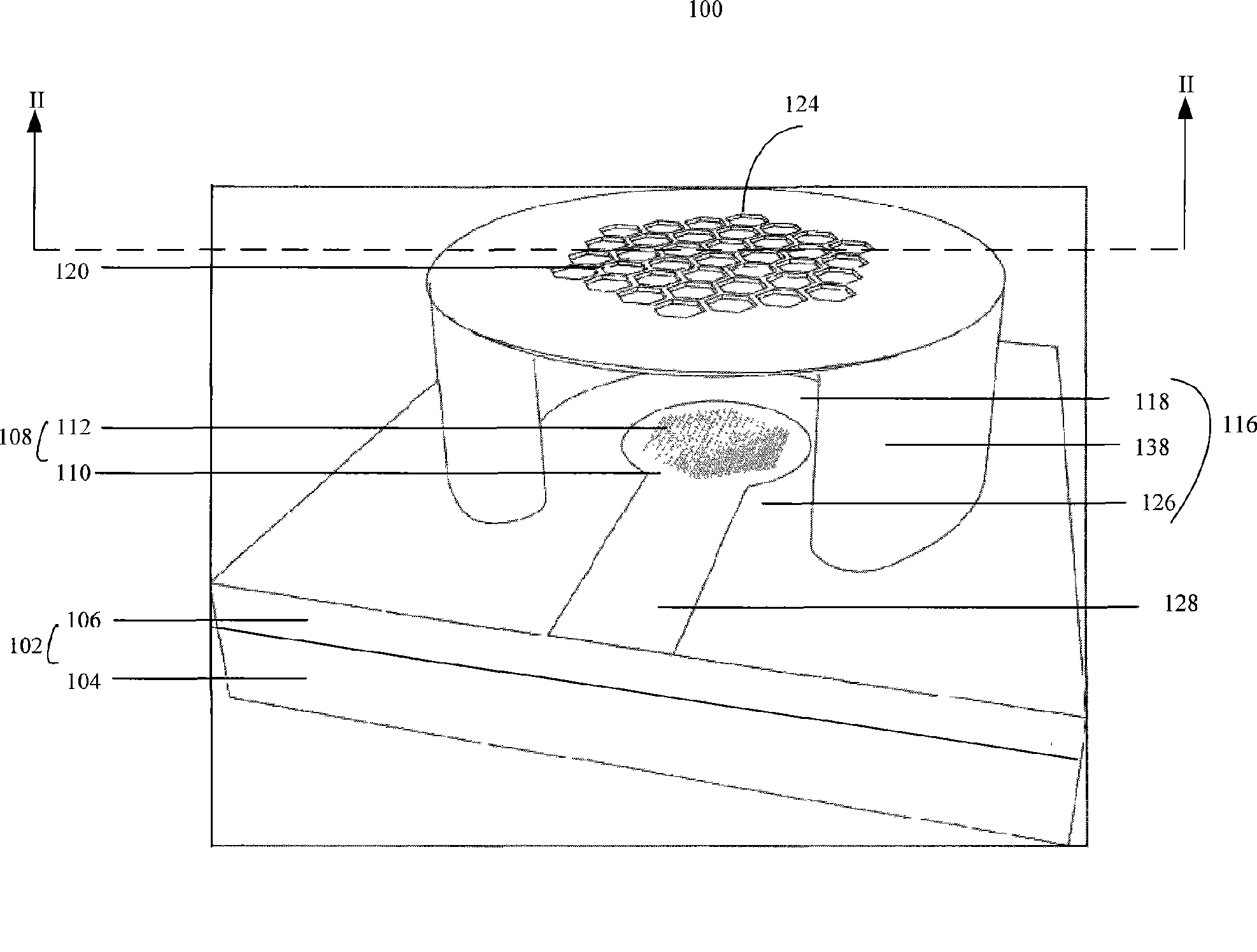

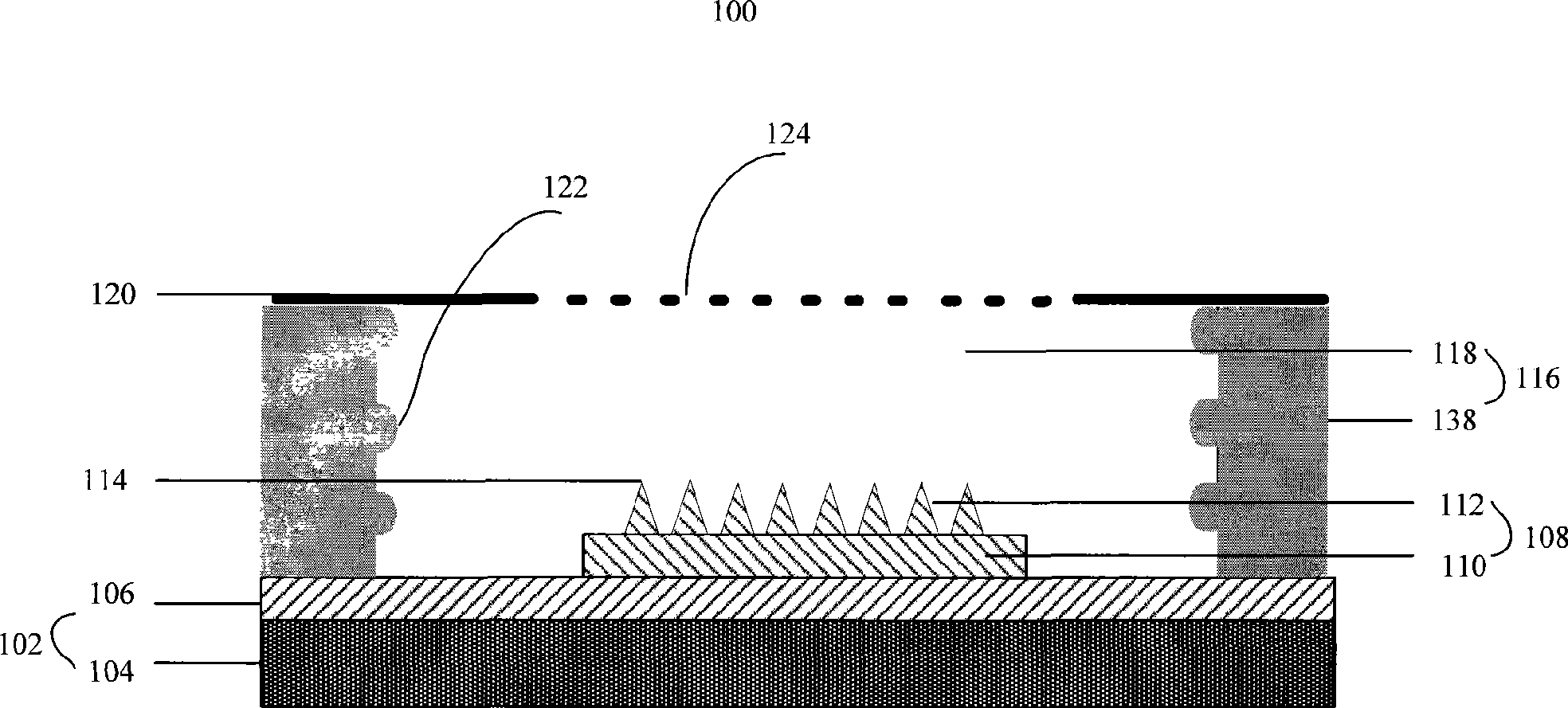

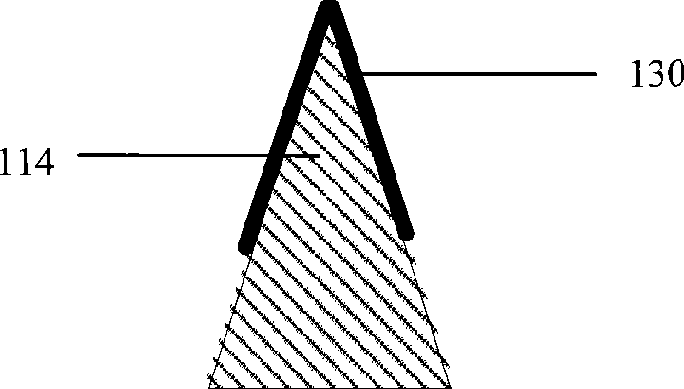

[0016] see figure 1 and figure 2 The embodiment of the technical solution provides a field emission electron source 100, which includes: an insulating substrate 102, a cathode emitter electrode 108 disposed on the upper surface of the insulating substrate 102, and a spacer 116 disposed on the upper surface of the insulating substrate 102, And a metal grid 120 is disposed on the separator 116, and the metal grid 120 further extends above the cathode emitter electrode 108, wherein the cathode emitter electrode 108 includes a cathode electrode 110 and a cathode emitter 112 disposed on the on the cathode electrode 110.

[0017] The insulating substrate 102 is an insulating substrate, such as an SOI (Silicon-On-Insulator, silicon on insulating substrate) substrate or a glass substrate. In this embodiment, an SOI substrate is preferably used as the insulating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com