Process for automatically detecting silicon chip edge

An automatic detection and silicon chip technology, applied in the direction of semiconductor/solid-state device testing/measurement, can solve the problems of inability to accurately locate detection points, poor efficiency and accuracy, and poor data analyzability, so as to improve detection and monitoring efficiency, Effects that enhance accuracy and improve analyzability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

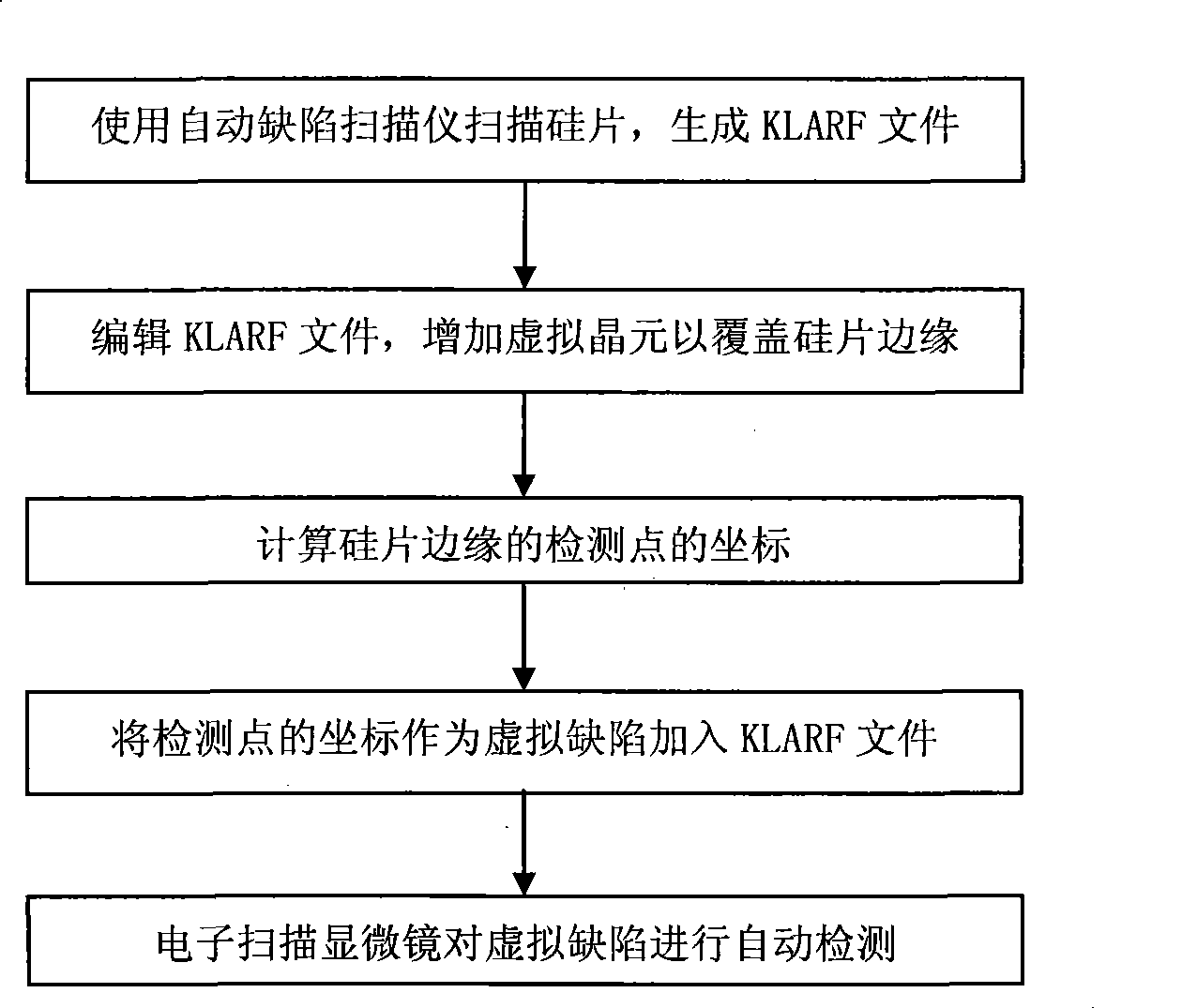

[0020] see figure 1 , the method for monitoring silicon chip edge of the present invention comprises the steps:

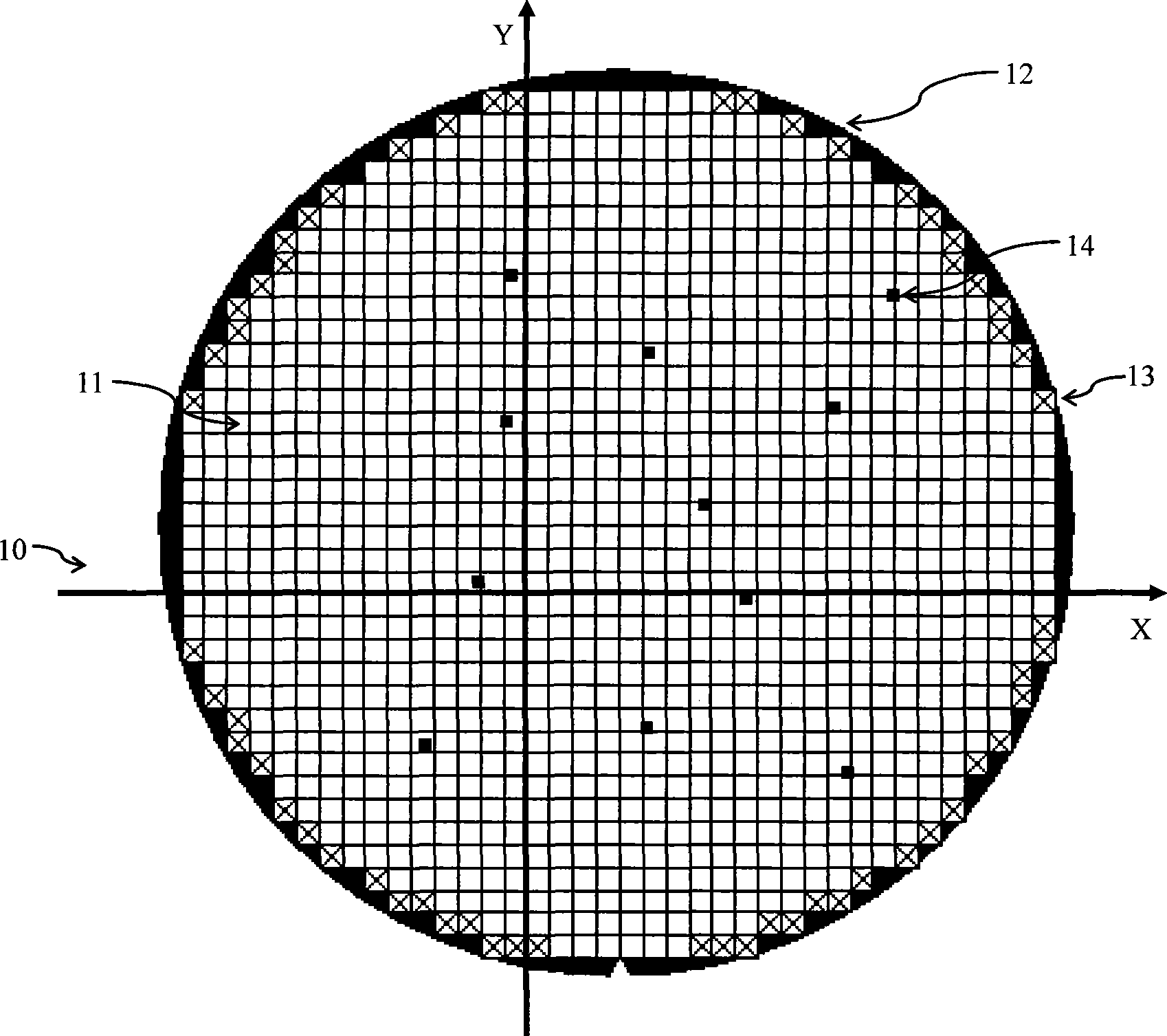

[0021] In the first step, the silicon wafer is scanned by an automatic defect detector, and the scanning result is saved as a file in KLARF format. When the automatic defect detector scans the silicon wafer, it can record the size and coordinates of each real defect on the silicon wafer.

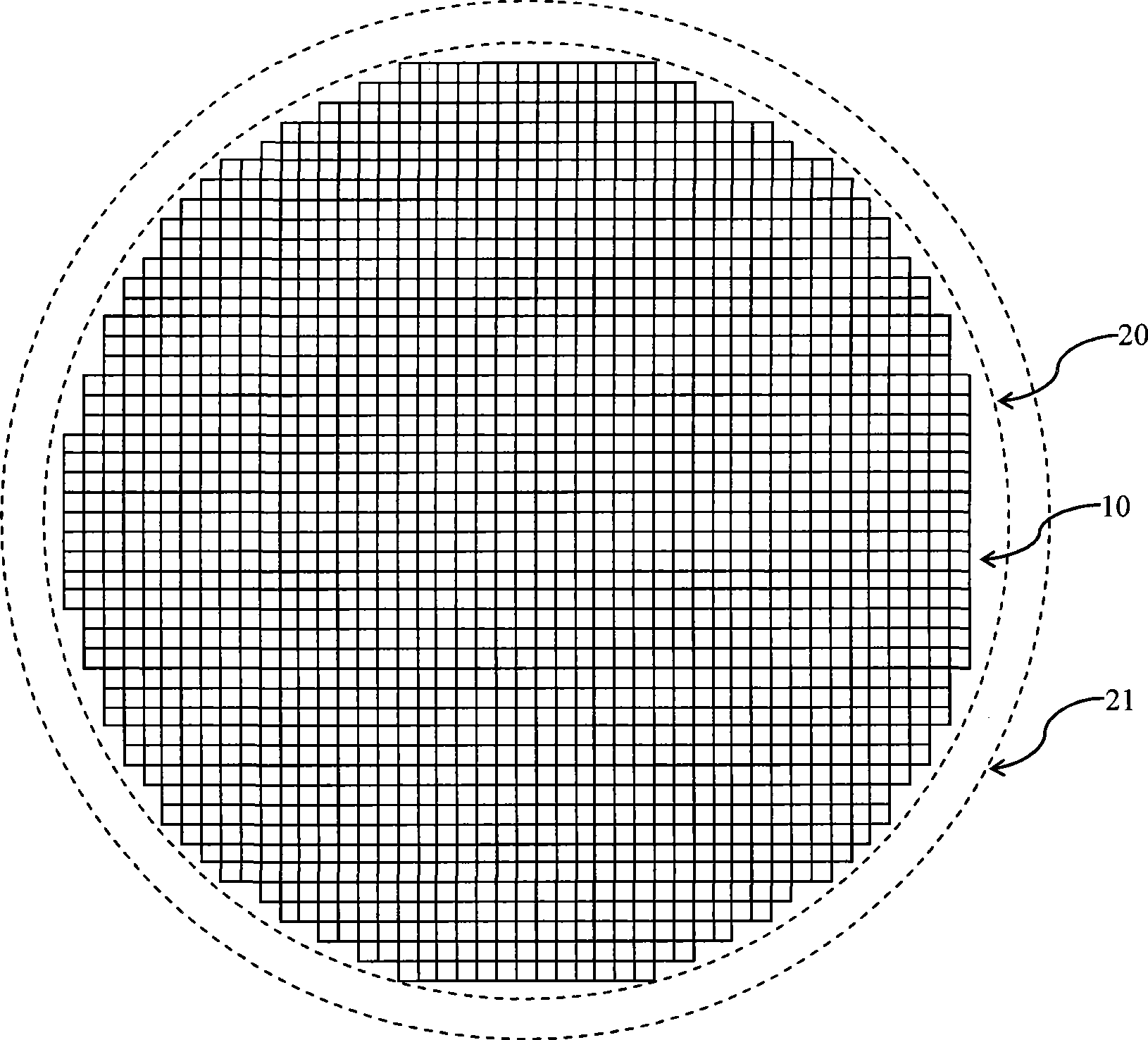

[0022] In the second step, a virtual wafer is added to the KLARF file saved in the first step, and the virtual wafer completely covers the edge of the entire silicon wafer. After the virtual wafer is added, the total area covered by the actual wafer and the virtual wafer of the KLARF file is larger than the actual area of the silicon wafer.

[0023] The third step is to calculate the coordinates of the detection points on the edge of the silicon wafer in the coordinate system adopted by the KLARF file. The coordinate system used in the KLARF file is customized by the automat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com