Vertical interconnecting through-hole for three-dimensional systematic encapsulation, and preparation thereof

A system-level packaging, vertical interconnection technology, applied in the field of vertical interconnection via structure design and preparation, can solve the problems of increased electromagnetic radiation and return loss, and achieve the purpose of reducing electromagnetic return loss, reducing electromagnetic radiation, avoiding cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

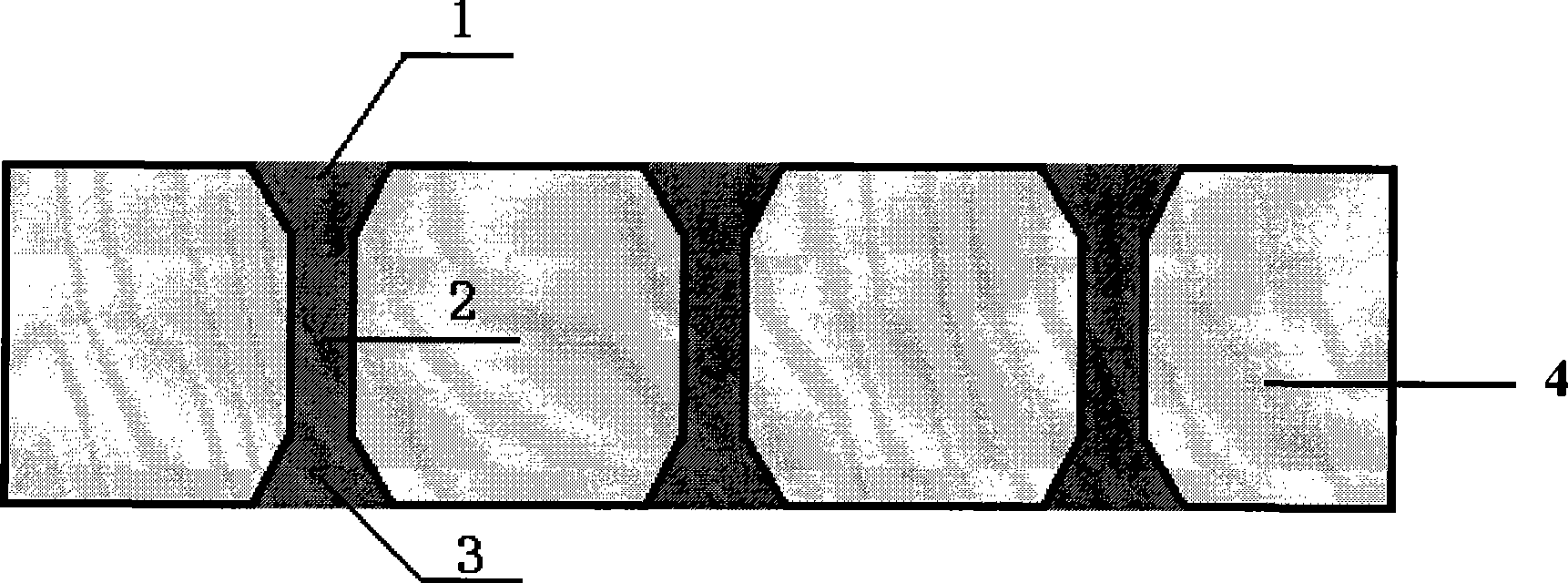

[0042] Embodiment 1. Vertical interconnection via holes are prepared on the silicon wafer on which the flash memory circuit has been fabricated.

[0043] The steps are as figure 2 shown, including:

[0044] 1. Choose a silicon chip that has already produced a flash memory circuit or other integrated circuits, such as figure 2 (a), and carry out carrier bonding;

[0045]2. Protect the circuit part on the silicon wafer, and use a mask to perform the first DRIE via etching with a dip angle at the position where the vertical via hole connection in the silicon wafer is required to form the upper conical part of the via hole. Among them, SF 6 Gas flow rate 130sccm, C 4 f 8 The gas flow rate is 100 sccm, the power of the slide stage is 13W, the power of the coil is 600W, and the APC (automatic pressure control) is selected as 60. After every 6s of etching, passivation is performed for 9s, and the etching and passivation are alternately performed to form sidewalls with slopes ...

Embodiment 2

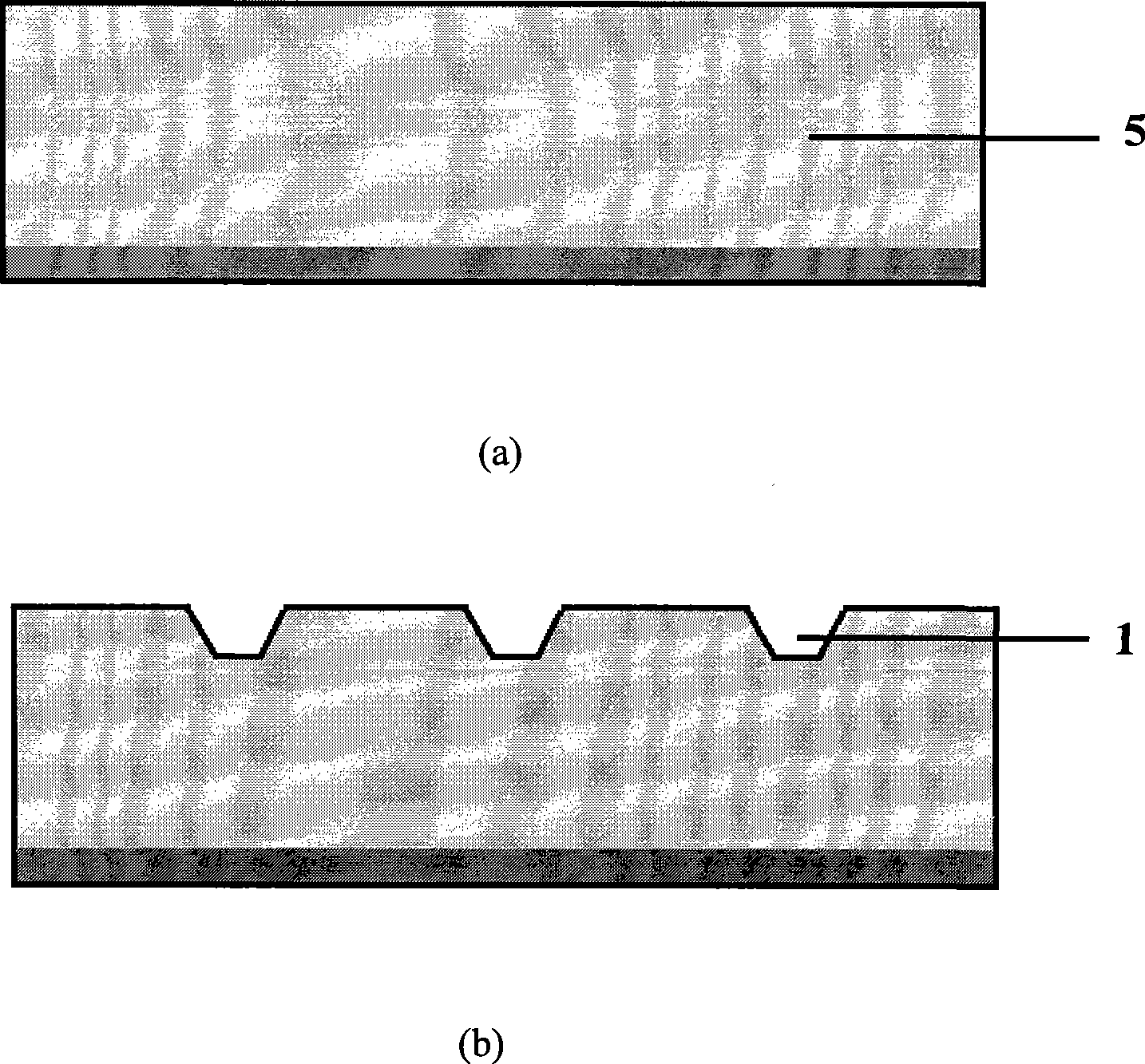

[0051] Embodiment 2: Vertical interconnection via holes are prepared on the SOI wafer.

[0052] refer to image 3 , whose steps include:

[0053] 1. Select SOI silicon wafer, such as image 3 as shown in (a);

[0054] Protect the circuit part of the device layer on the silicon wafer, and use a mask to perform the first DRIE via hole etching with an angle at the position where the vertical via hole connection is required in the silicon wafer, and make the upper end angle of the required size. The reference data is SF 6 Gas flow rate 130sccm, C 4 f 8 The gas flow rate is 100 sccm, the power of the slide stage is 13W, the power of the coil is 600W, and the APC (automatic pressure control) is selected as 60. Passivation for 9s after each etching for 6s, etching and passivation are performed alternately, and finally form a sidewall with a slope, such as image 3 as shown in (b);

[0055] 2. Adjust the mask for the vertical via holes in the etched silicon wafer, and perform ...

Embodiment 3

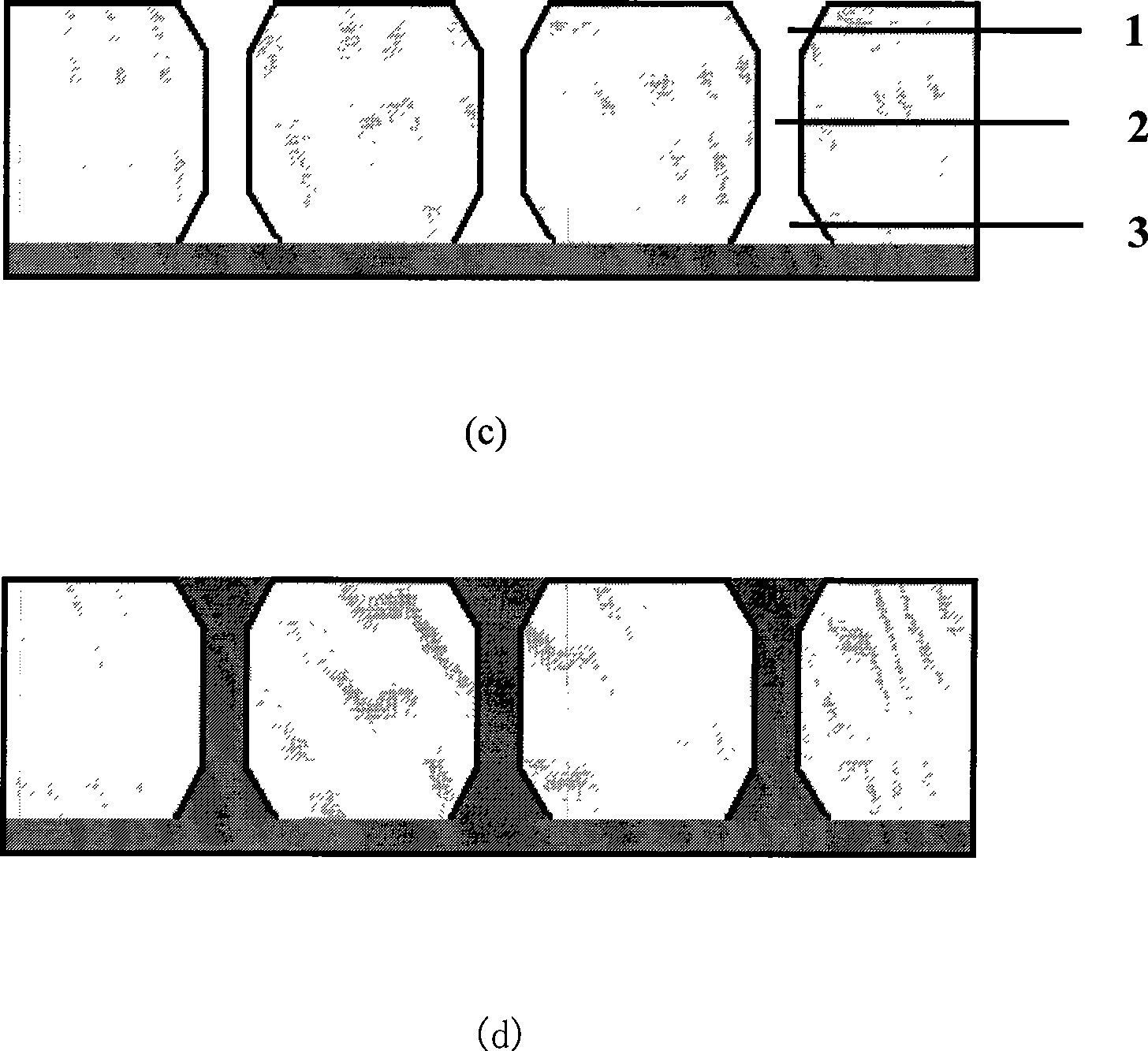

[0063] Embodiment 3: A standard silicon wafer with an integrated circuit processed on the upper surface is prepared for vertical interconnection via holes.

[0064] refer to Figure 4 , whose steps include:

[0065] 1. Protect the circuit part on the silicon chip, and use a mask to perform the first DRIE via hole etching with an inclination angle at the position where the vertical via hole connection in the silicon chip is required, and make the upper end inclination angle of the required size; refer to the data for SF 6 Gas flow rate 130sccm, C 4 f 8 The gas flow rate is 100 sccm, the power of the slide stage is 13w, the power of the coil is 600w, and the APC (automatic pressure control) is selected as 60. After etching for 6s, passivate for 9s to form sidewalls with slopes, such as Figure 4 as shown in (a);

[0066] 2. Add silicon carrier protection on the upper surface of the silicon wafer, such as Figure 4 As shown in (b); and thinning the back, such as Figure 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com