Gel composition for eyes and preparation method thereof

A kind of technology of ophthalmic gel and composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

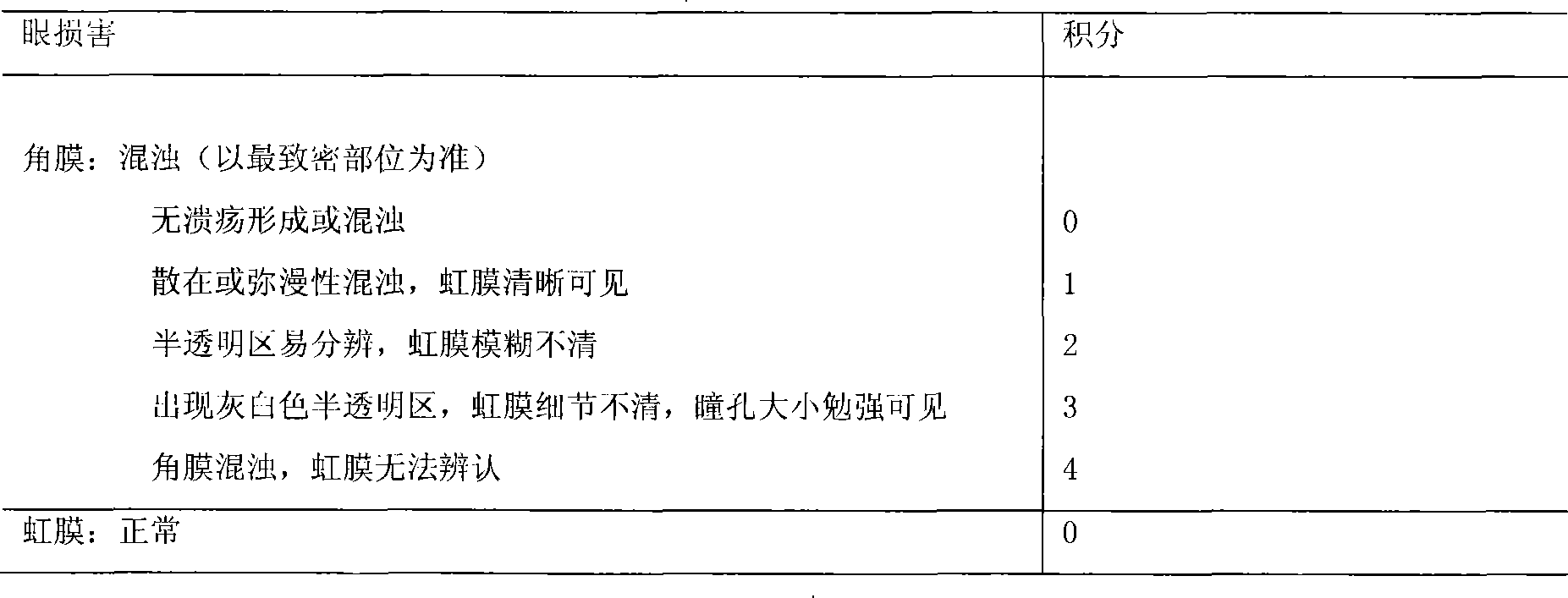

Method used

Image

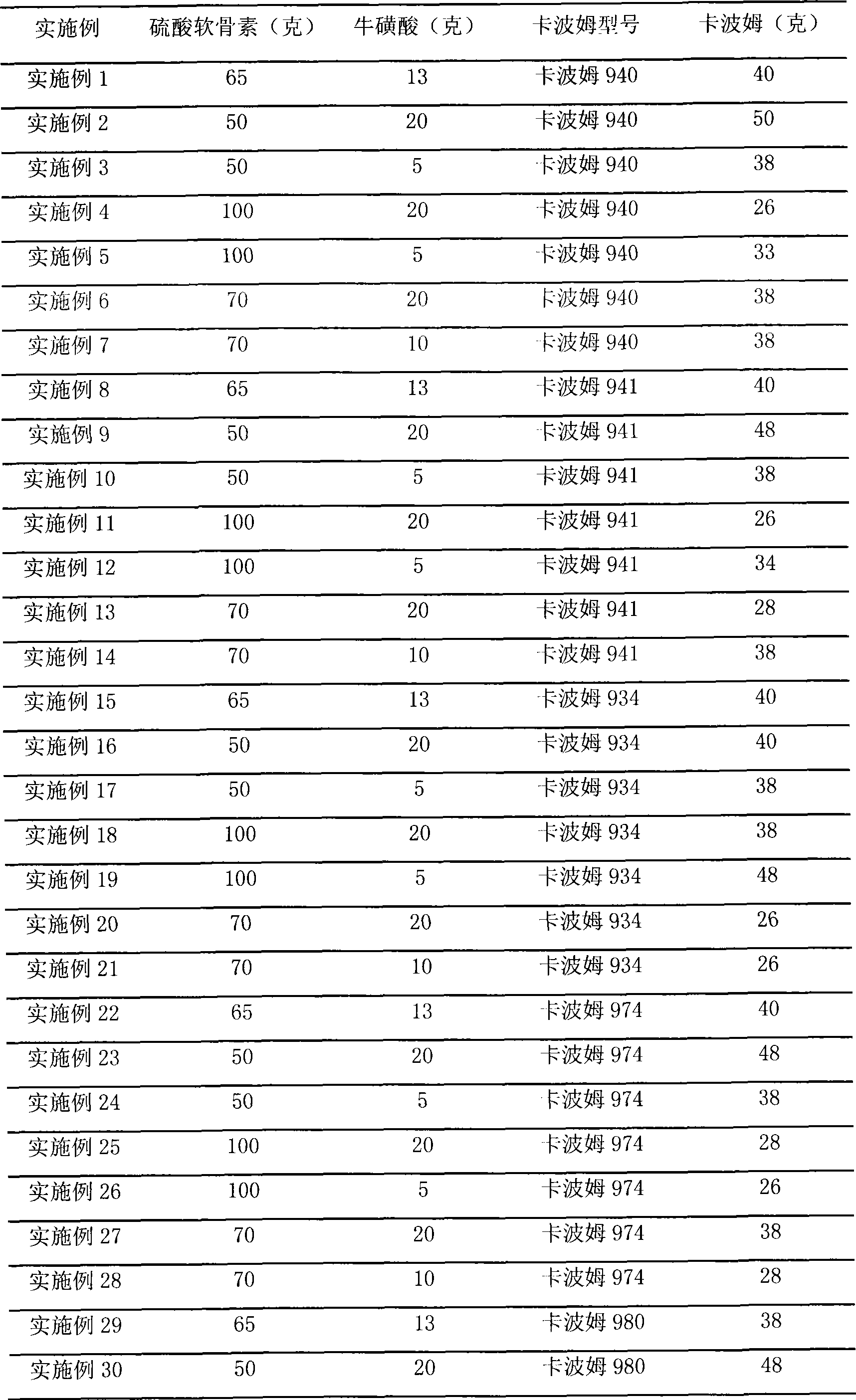

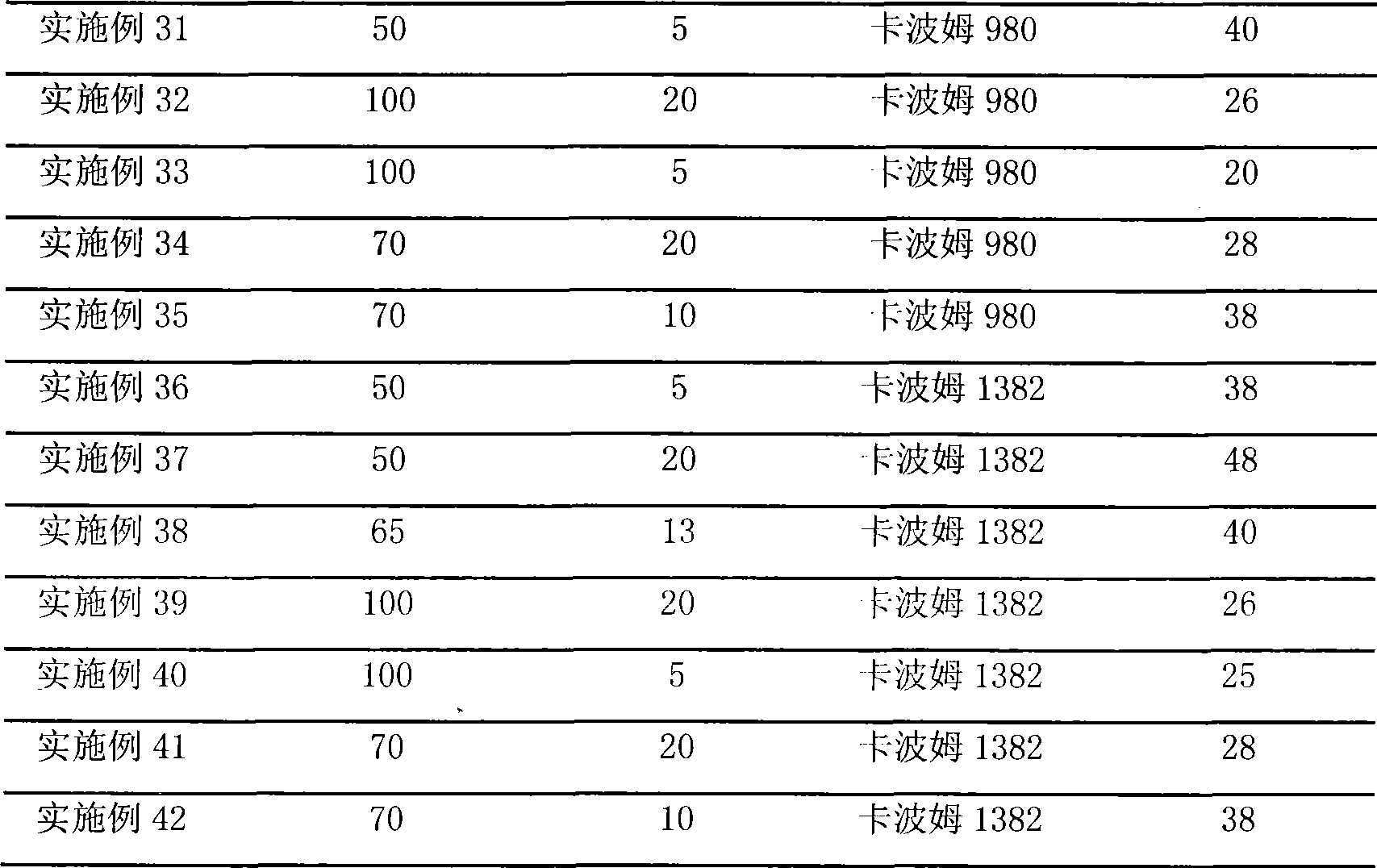

Examples

Embodiment 1-7

[0037] Preparation method:

[0038] (1) Weigh the prescribed amount of Carbomer 940 and sprinkle it on the water surface of 1000 ml of water for injection for 3 times, leave it overnight to make it fully swell and dissolve, and filter it with a 200-mesh sieve cloth as solution I.

[0039] (2) Weigh the prescribed amount of chondroitin sulfate, taurine, benzalkonium chloride, and glycerin and dissolve them in 2000 ml of water for injection in sequence, and filter with a 0.22 μm microporous membrane to obtain solution II.

[0040] (3) Solution II was slowly added to solution I, and ground while adding to make it fully mixed, and then 10% sodium hydroxide solution was added dropwise to form a gel, and the pH value was adjusted to about 6.5.

[0041] (4) Add water for injection to 4000g, grind well, and defoam.

[0042] (5) Sterilize with circulating steam at 100°C for 30 minutes, let cool and fill (4g / bottle).

Embodiment 8-14

[0044] method

[0045] (1) Weigh the prescribed amount of Carbomer 934 and sprinkle it on the water surface of 1000 ml of water for injection for 3 times, place it overnight to make it fully swell and dissolve, and filter it with a 200-mesh sieve cloth as solution I.

[0046] (2) Weigh the prescribed amount of chondroitin sulfate, taurine, benzalkonium chloride, and glycerin and dissolve them in 2000 ml of water for injection in sequence, and filter with a 0.22 μm microporous membrane to obtain solution II.

[0047] (3) Solution II was slowly added to solution I, and ground while adding to make it fully mixed, and then 10% sodium hydroxide solution was added dropwise to form a gel, and the pH value was adjusted to about 6.5.

[0048] (4) Add water for injection to 4000g, grind well, and defoam.

[0049] (5) Sterilize with circulating steam at 100°C for 30 minutes, let cool and then fill.

Embodiment 15-21

[0051] Preparation method:

[0052] (1) Weigh the prescribed amount of Carbomer 941 and sprinkle it on the water surface of 1000 ml of water for injection for 5 times, leave it overnight to make it fully swell and dissolve, and filter it with a 200-mesh sieve cloth as solution I.

[0053] (2) Weigh the prescribed amount of chondroitin sulfate, taurine, benzalkonium chloride, and glycerin and dissolve them in 2000 ml of water for injection in sequence, and filter with a 0.22 μm microporous membrane to obtain solution II.

[0054] (3) Solution II was slowly added to solution I, and ground while adding to make it fully mixed, and then 10% sodium hydroxide solution was added dropwise to form a gel, and the pH value was adjusted to about 6.5.

[0055] (4) Add water for injection to 4000g, grind well, and defoam.

[0056] (5) Sterilize with circulating steam at 100°C for 30 minutes, let cool and then fill.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com