Tower-top eddy flow purification method and device of recycle hydrogen desulfurizing tower

A technology for circulating hydrogen desulfurization towers and desulfurization towers, which is applied to chemical instruments and methods, separation methods, and separation of dispersed particles, and can solve problems such as solvent foaming and absorption liquid loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] The present invention is further described below in conjunction with specific examples. However, it should be understood that these examples are only used to illustrate the present invention and not to limit the scope of the present invention. The test methods for which specific conditions are not indicated in the following examples are generally in accordance with conventional conditions, or in accordance with the conditions suggested by the manufacturer. All percentages and parts are by weight unless otherwise indicated.

[0046] Separation of gas-rich amine liquid in the improvement of IV and V hydrogenation units of Sinopec Zhenhai Refining and Chemical Co., Ltd. device

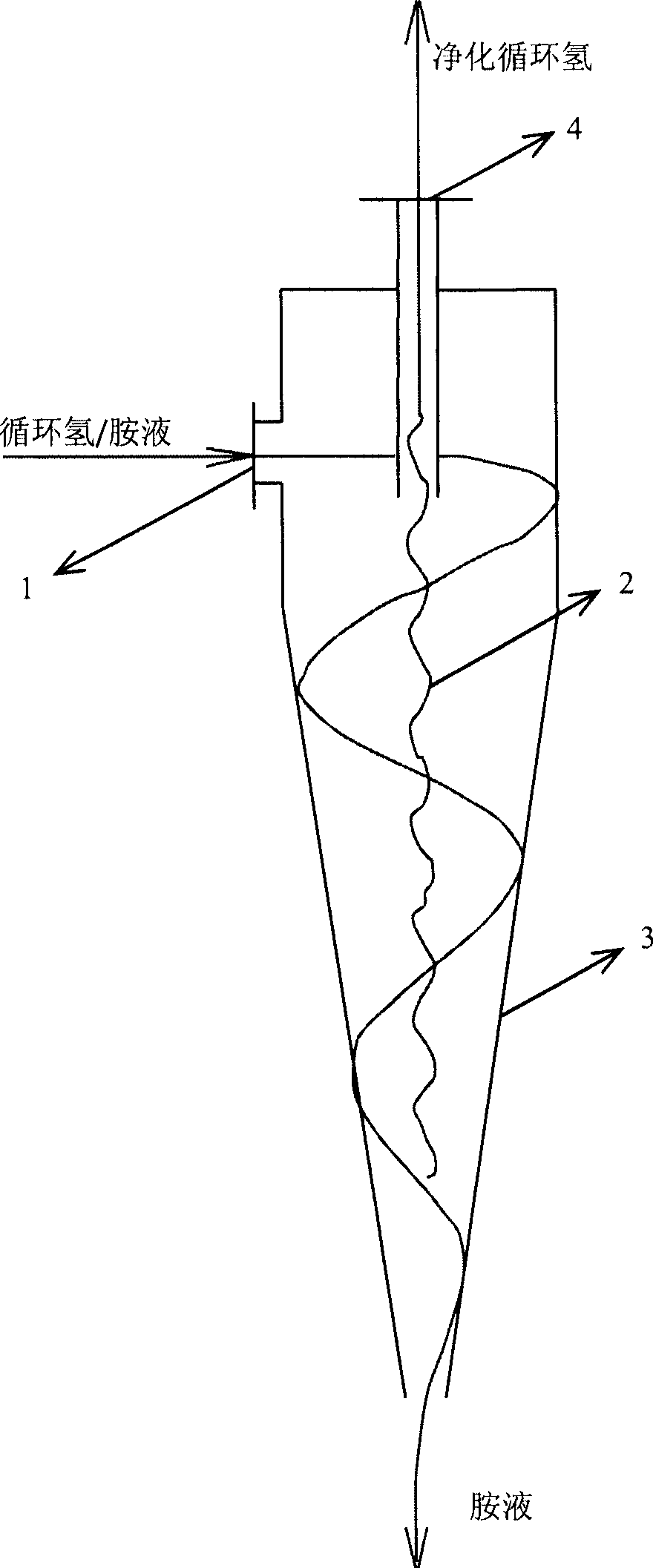

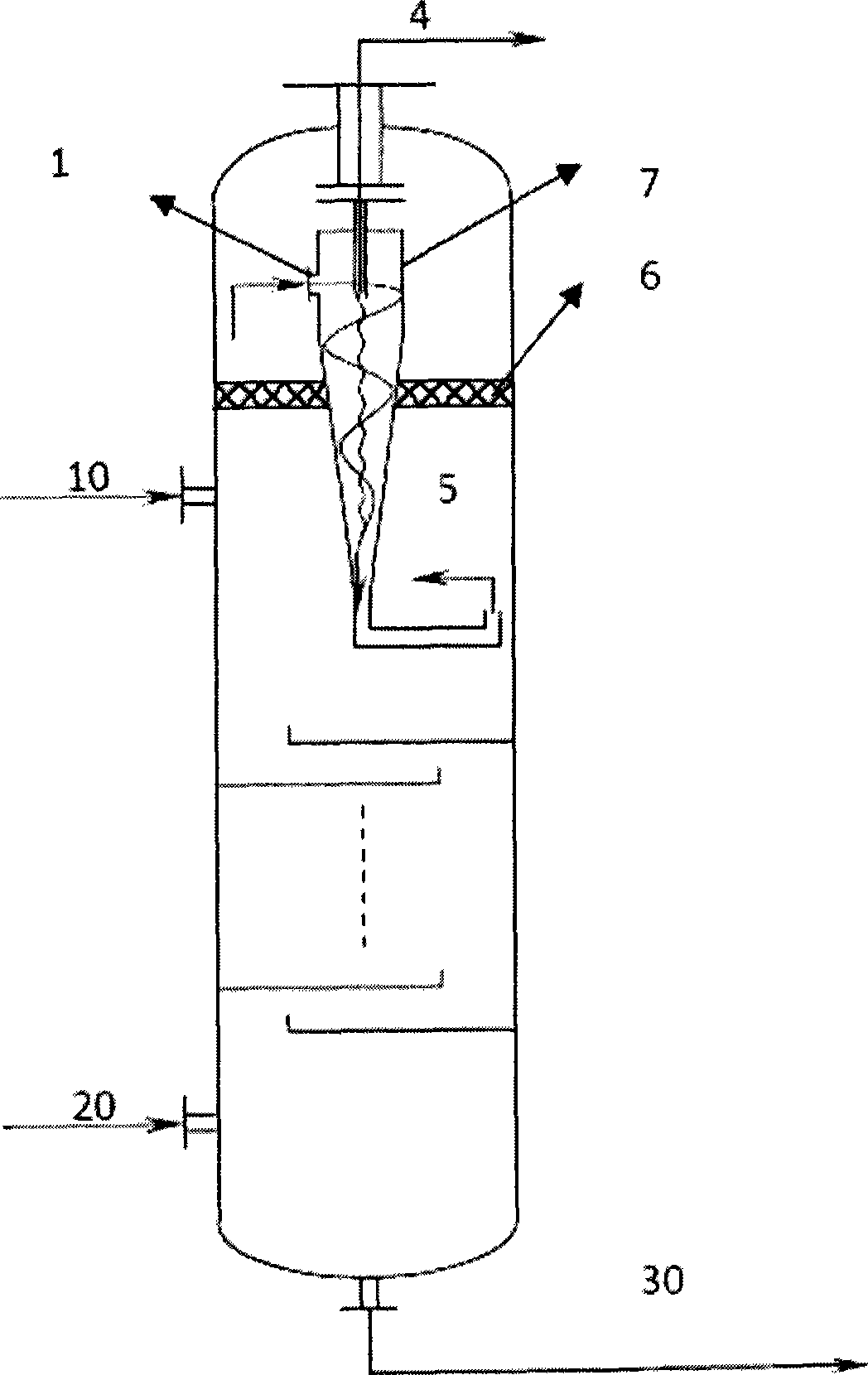

[0047] The operating process of the gas-rich amine liquid separator is as follows: Figure 1-2 shown. Its fluid properties are shown in Table 1 below:

[0048] Table 1

[0049] serial number project Project Description 1 medium Desulfurization rich gas 2 Operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com