Preparation method of nickel based metal load type catalyst

A supported catalyst, base metal technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. The problems of cumbersome process and increased energy consumption can achieve the effect of high catalytic activity and selectivity, simplifying the activation process and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

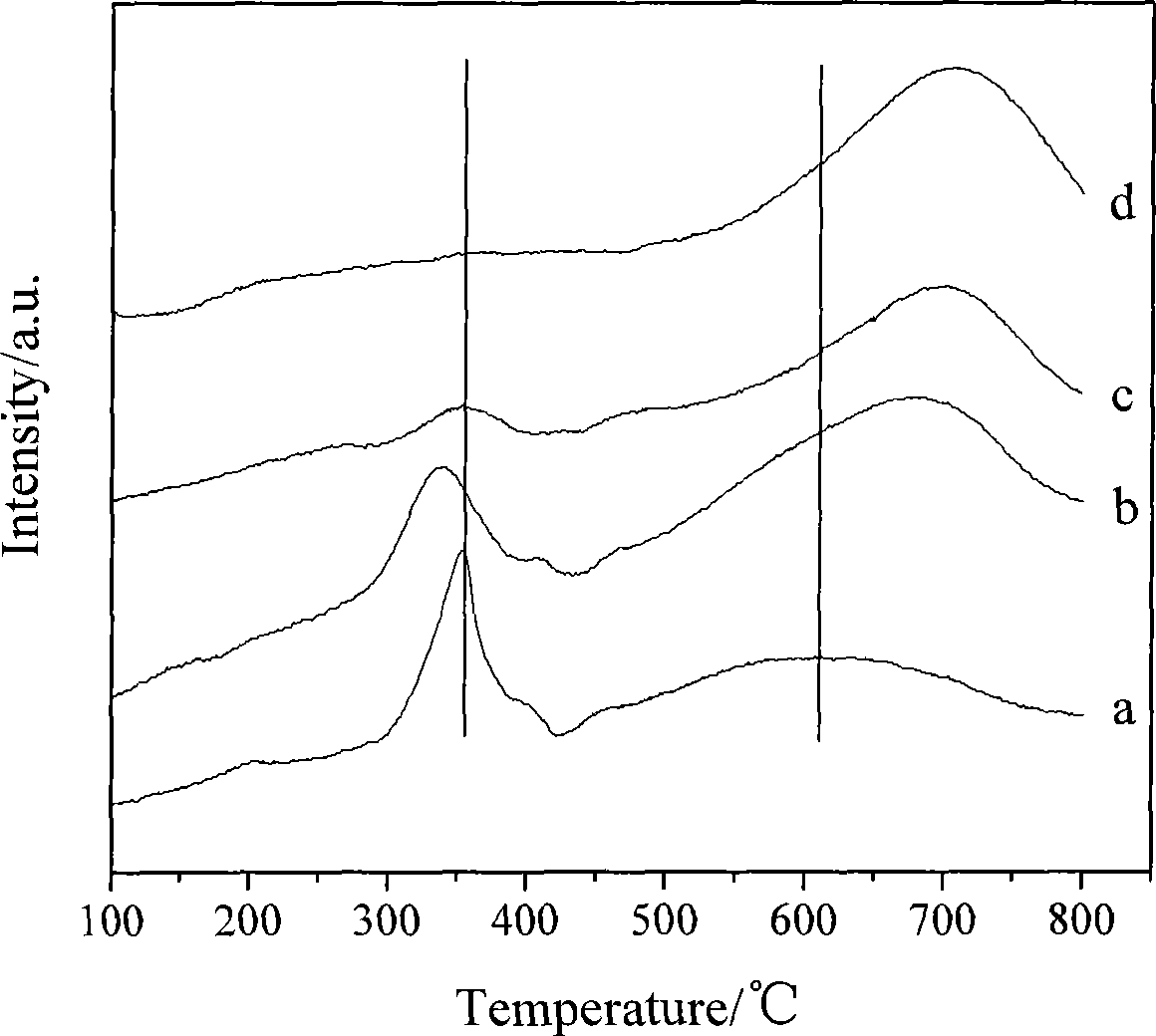

[0021] Example 1: 1.5g NiMgAl-LDHs hydrotalcite is loaded into a stainless steel reactor, and reduced by pure hydrogen, the hydrogen flow rate is 30ml / min, the reduction temperature is programmed from room temperature to 500°C, and the heating rate is 5°C / min, keeping 2h. The catalyst after direct reduction activation is recorded as NiMgAl-LDHs-500(R).

Embodiment 2

[0022] Example 2: 1.5g NiMgAl-LDHs hydrotalcite is loaded into a stainless steel reactor, and reduced by pure hydrogen, the hydrogen flow rate is 30ml / min, the reduction temperature is programmed from room temperature to 550°C, and the heating rate is 5°C / min, keeping 2h. The catalyst after direct reduction activation is recorded as NiMgAl-LDHs-550(R).

Embodiment 3

[0023] Example 3: 1.5g NiMgAl-LDHs hydrotalcite is loaded into a stainless steel reactor, and reduced by pure hydrogen, the hydrogen flow rate is 30ml / min, the reduction temperature is programmed from room temperature to 600°C, and the heating rate is 5°C / min, keeping 2h. The catalyst after direct reduction activation is recorded as NiMgAl-LDHs-600(R).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com