Automatic feeding device for mixed flow assembly line

A technology of automatic feeding and assembly line, used in transportation and packaging, metal processing equipment, metal processing and other directions, can solve the problems of poor versatility, large size, and inability to distinguish different parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

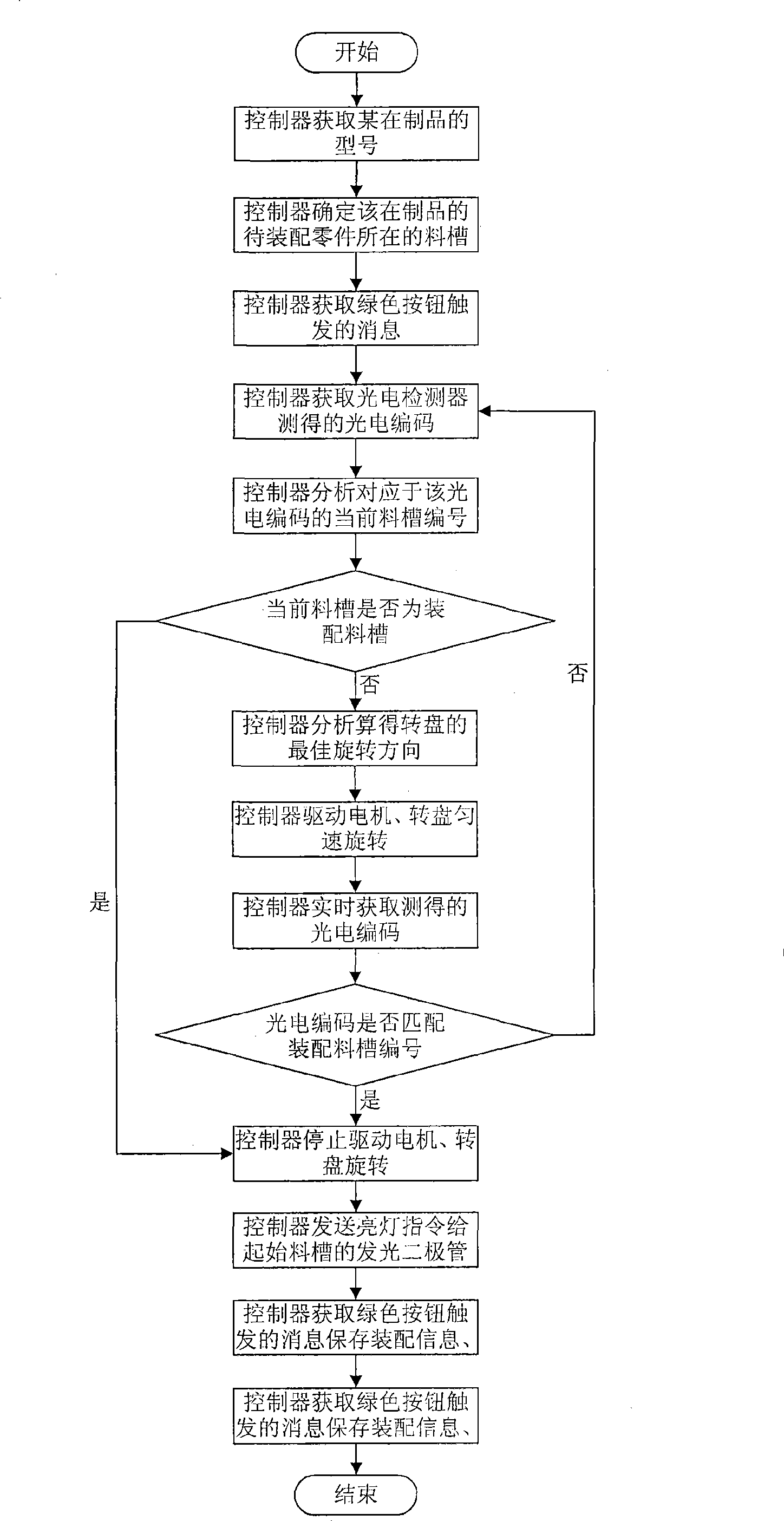

[0016] The present invention will be described in further detail below in conjunction with accompanying drawing and example.

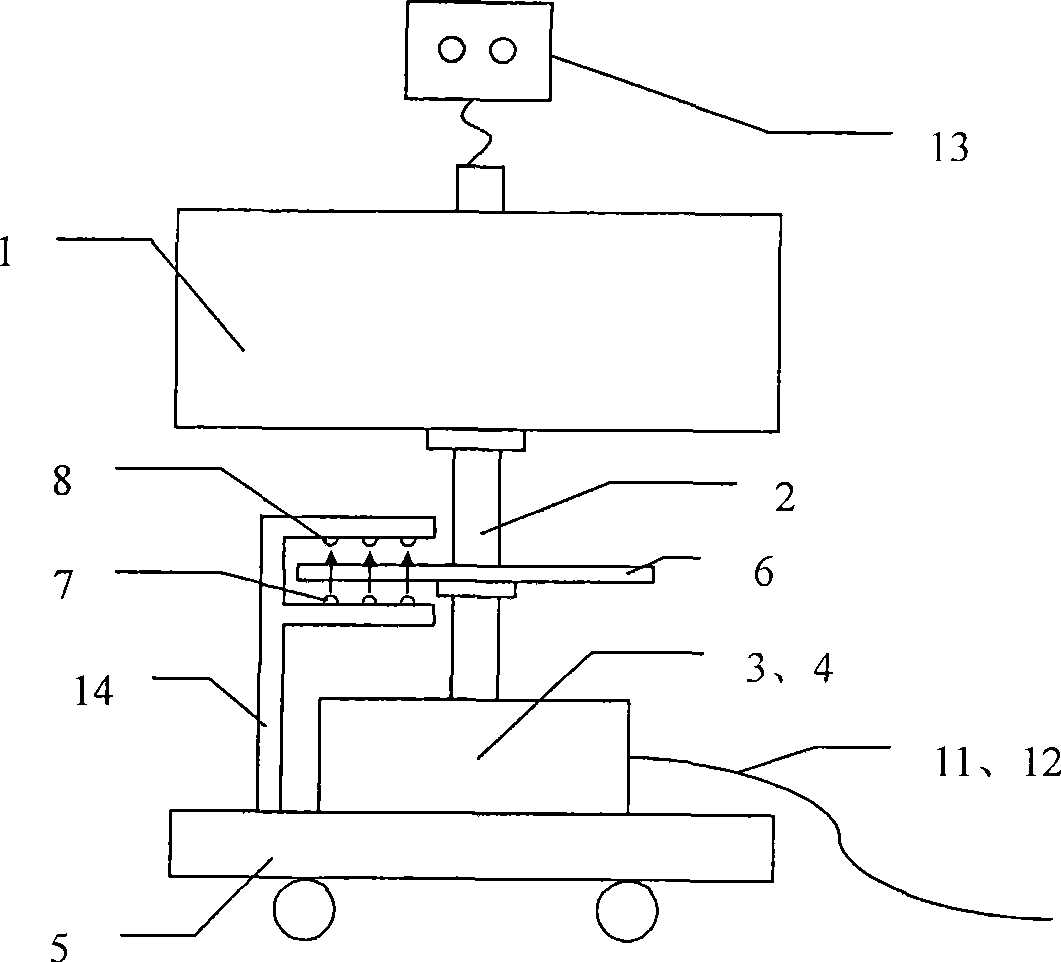

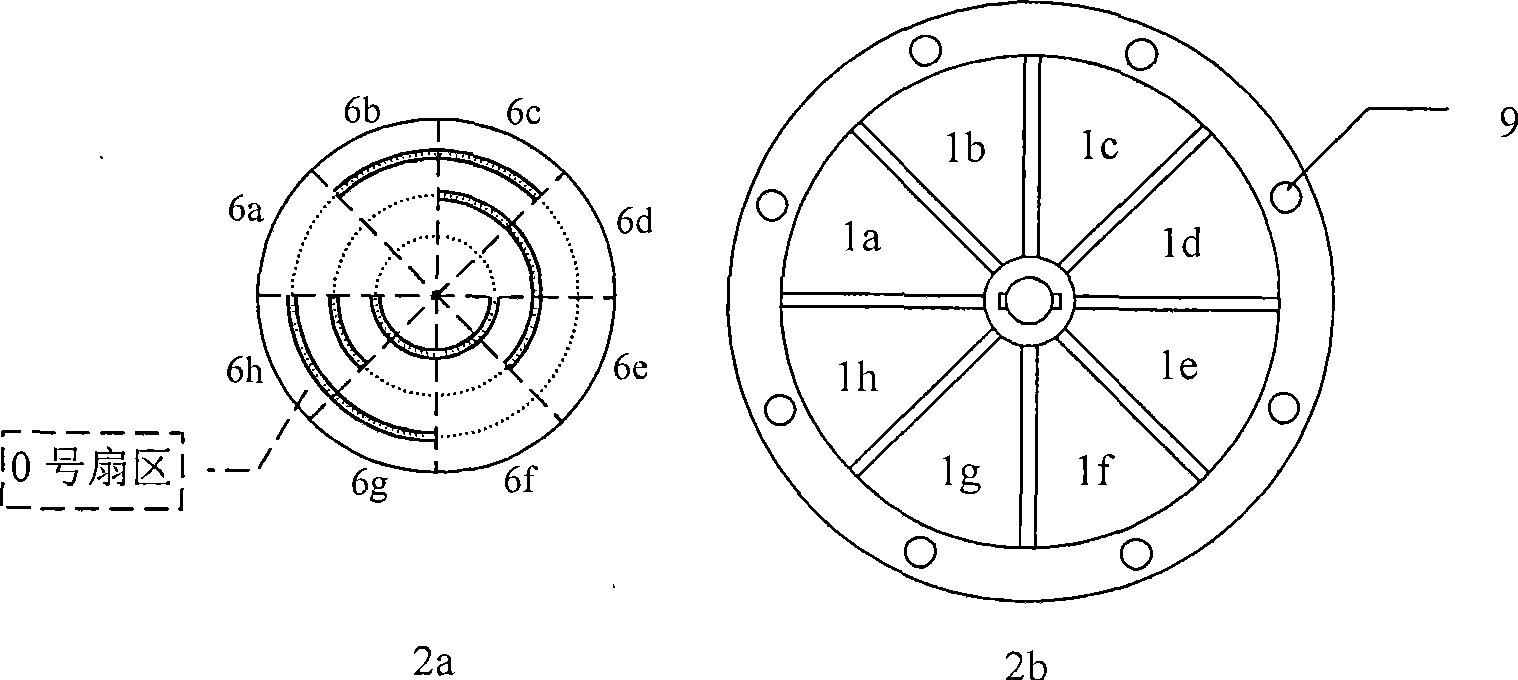

[0017] like figure 1 Shown, base 5 has rollers, so that the worker moves device. A photodetector 14 , a controller 3 and a motor 4 are fixed on the base 5 . The photodetector 14 is located next to the grating 6 and consists of a light emitting diode 7 and a photodiode 8 . The controller 3 is connected to the motor 4, analyzes and judges the WIP information of the mixed flow assembly line transmitted from the bus 12, calculates the rotation angle of the motor 4, and sends a pulse signal to drive the motor 4. The controller 3 is pre-configured with station part information, including the name, size, quantity of all parts to be assembled, the number of the trough where they are located, and the assembly sequence composed of all parts to be assembled. The motor 4 is connected to the bottom of the shaft 2 and can rotate at the same speed as the shaft 2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com