Postprocessing system of diesel engine

A post-processing, diesel engine technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of low heat utilization efficiency and high fuel consumption rate, and achieve the effect of extending interval, high energy utilization rate and reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

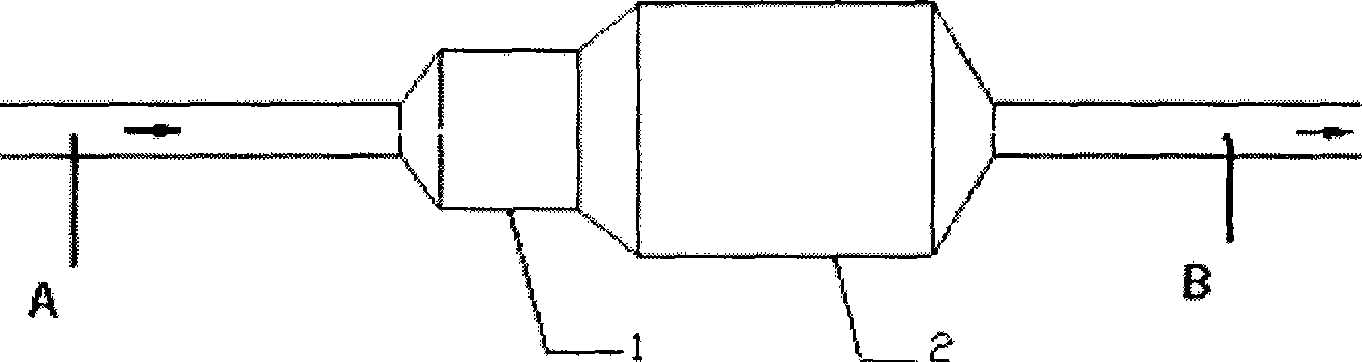

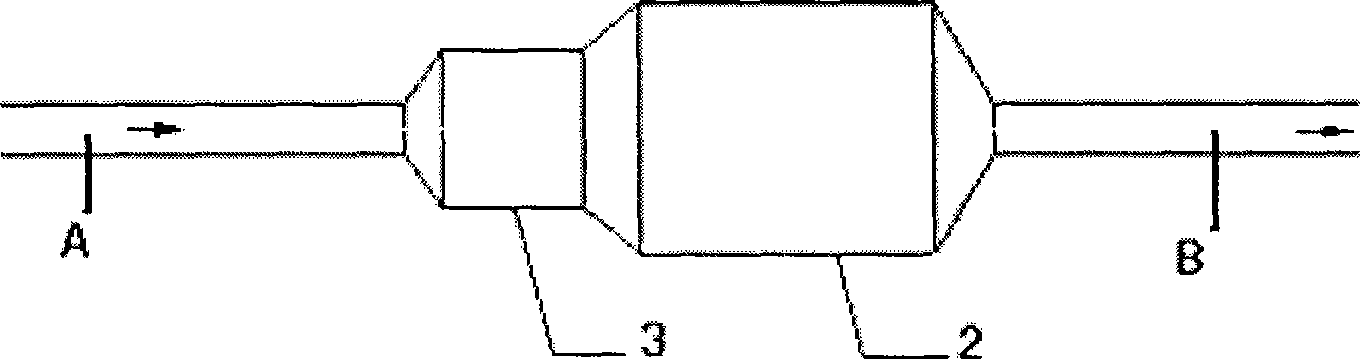

[0026] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

[0027] When the exhaust gas temperature of the engine is lower than 250°C, the partial flow-through metal filter coated with an oxidation catalyst can oxidize most of the HC and CO and some particulate matter in the exhaust of the diesel engine on the one hand, and can also oxidize NO in the exhaust is oxidized to NO 2, and at the same time capture a part of the particulate matter in the exhaust gas. When the unfiltered exhaust gas flows through the wall-flow ceramic filter, most of the particles contained in it will be filtered, and the total filtration efficiency of the two-stage filter can reach more than 95%. Since the metal filter oxidizes part of the particulate matter (including HC adhering to the particulate matter, etc.), the amount of particulate matter captured by the two-sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com