Differential pressure sensor

A differential pressure sensor and sensing element technology, applied in instruments, measuring fluid pressure, measuring pressure difference between multiple valves, etc., can solve the problems of low static pressure, high cost, and inability to output electrical signals, etc. Achieve the effect of increased static pressure and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

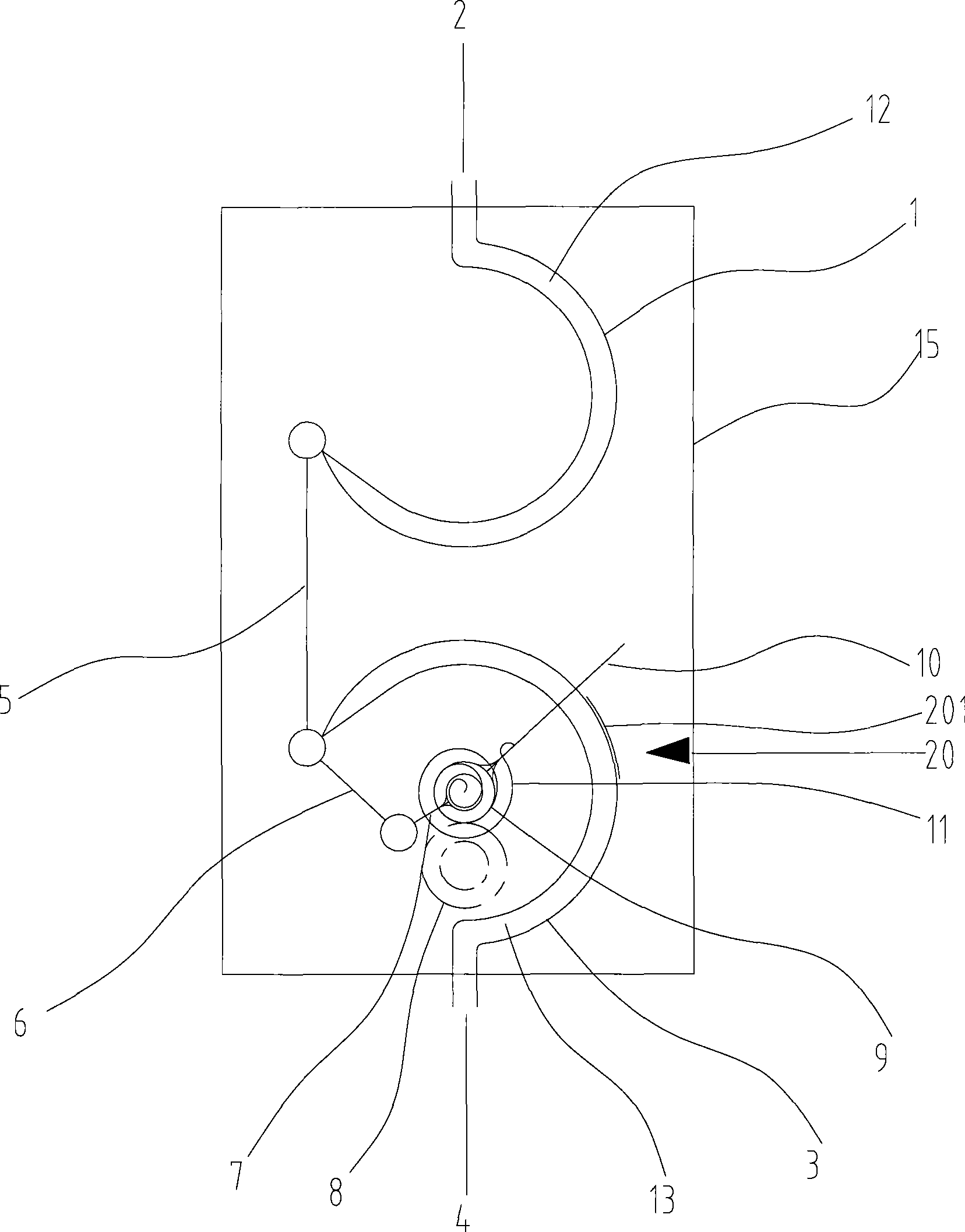

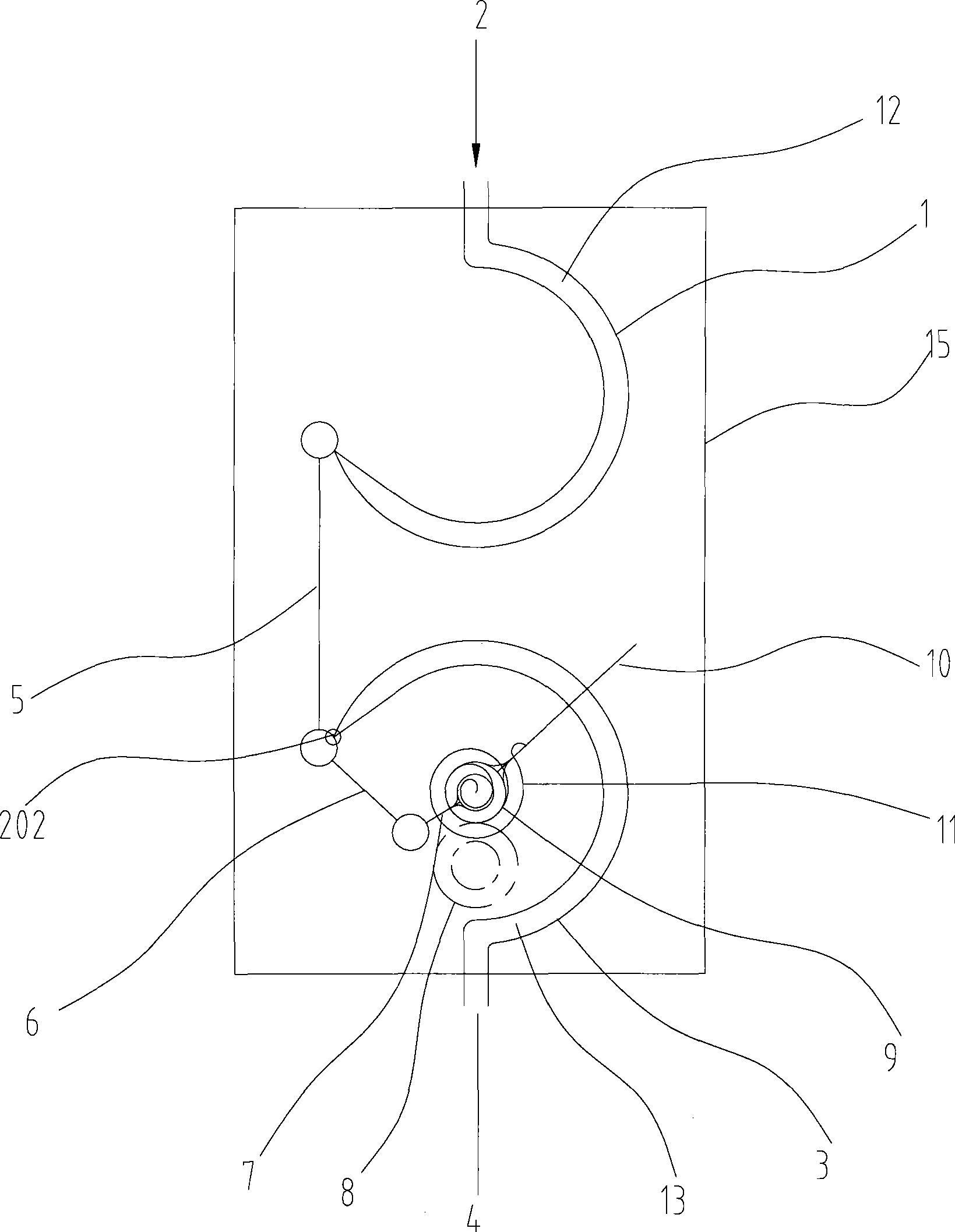

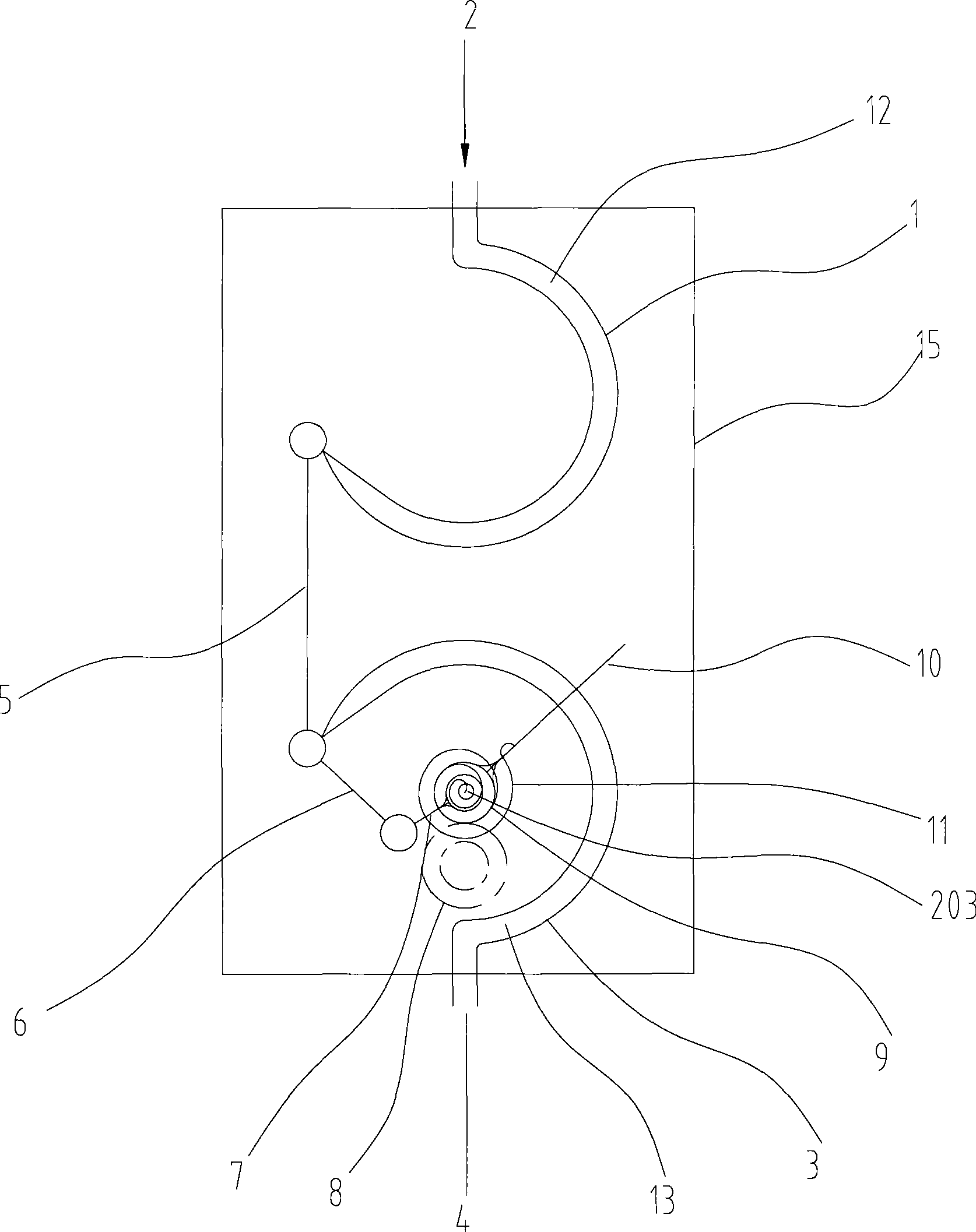

[0022] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0023] figure 1 A schematic structural diagram of a differential pressure sensor according to a first preferred embodiment of the present invention is shown. In this embodiment, the differential pressure sensor includes a package housing 15; first and second sensing elements 1, 3 and their first and second chambers 12, 13 respectively, the first chamber 12 has a The first pressure port 2 communicated, the second chamber 13 has a second pressure port 4 communicated with the outside world; used to transmit the deformation of the sensing elements 1, 3, amplified deformation transmission and amplification components; used to indicate the pressure a changing pointer 10; and a spring 11 for returning the pointer 10. In addition, the first and second pressure ports 2 and 4 are respectively used to connect with one test end of the container under tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com