Optical approaching correction, photo mask production and graphic method

A technology of optical proximity correction and manufacturing method, which is applied in the field of optical proximity correction, can solve problems such as shrinkage and device short circuit, and achieve the effects of preventing bridging and solving short circuit phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

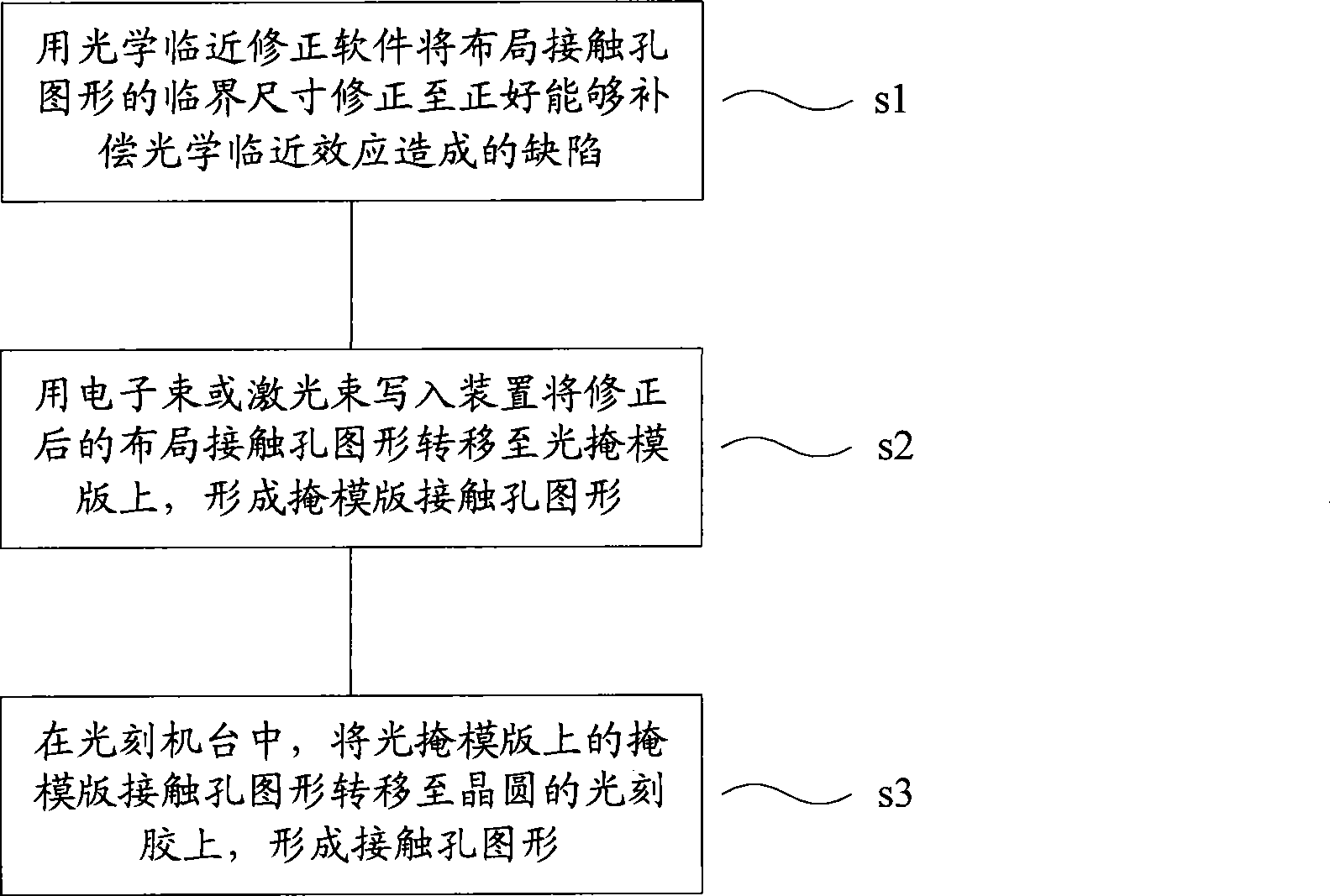

Method used

Image

Examples

Embodiment Construction

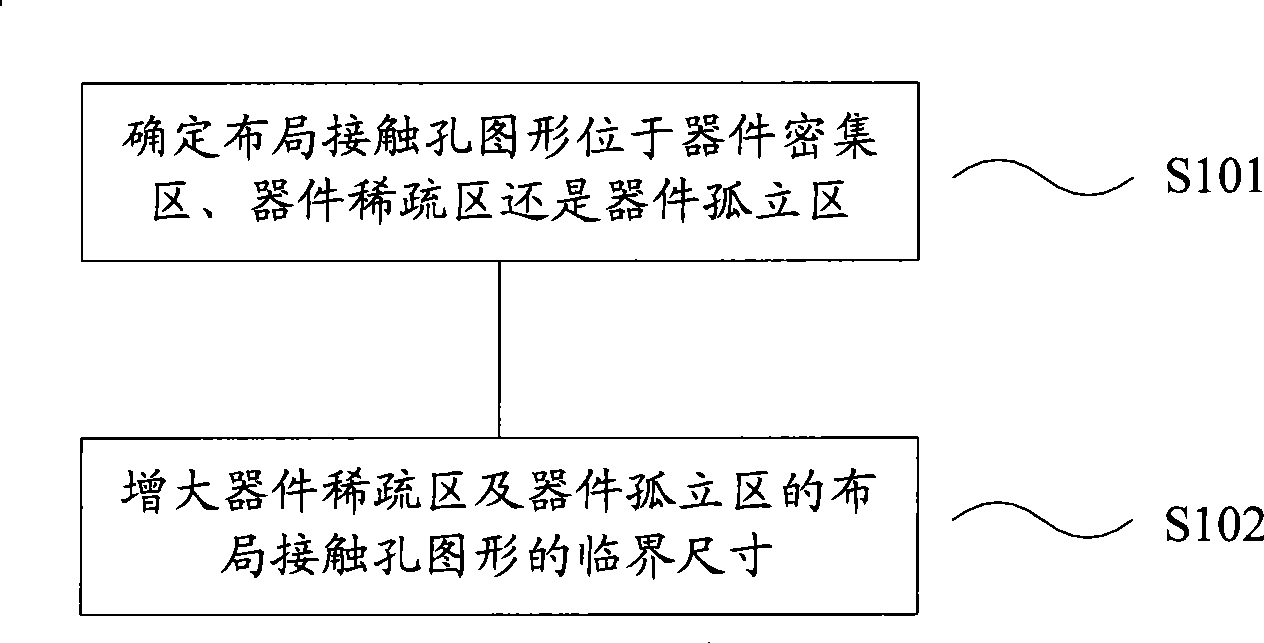

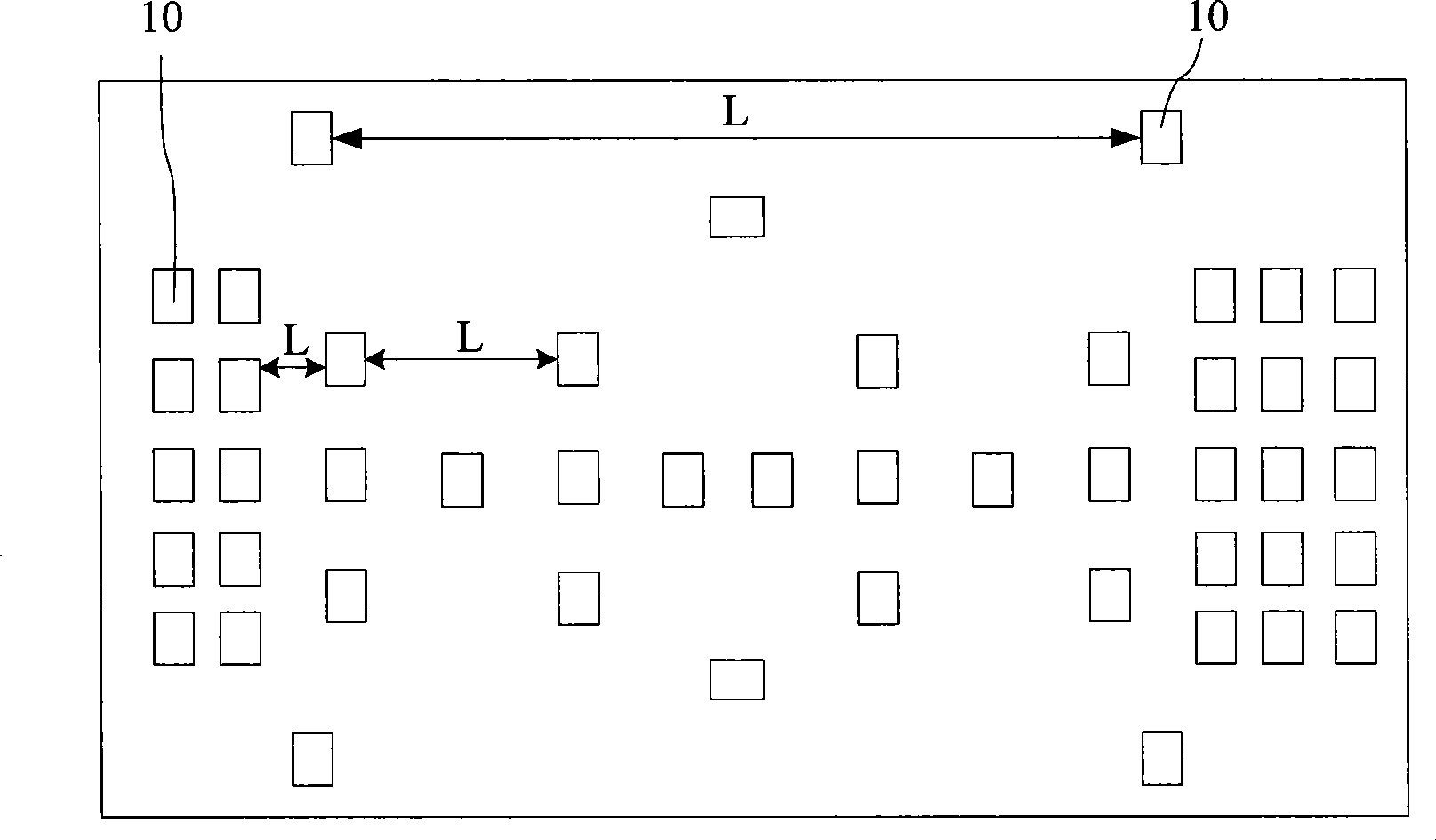

[0028] The present invention can selectively adjust the critical size of the layout contact holes in different regions by determining whether the layout contact hole pattern is located in the device dense area, the device sparse area or the device isolated area, and the layout contact hole pattern of the device sparse area and the device isolated area Increase the critical dimension of the wafer so that the subsequent contact holes formed on the wafer will not be lost because the critical dimension is too small. The increase of the contact hole causes the bridging between the contact holes, thereby effectively solving the short circuit phenomenon between the devices.

[0029] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0030] figure 2 It is a specific implementation flow chart of the optical proximity correction of the present invention. Such as figure 2 As shown, step S101 is execute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com