Biological freezing point brewing method for peach fermented wine

A technology for fermenting wine and freezing point, which is applied in the field of biological fermentation and brewing, can solve the problems of unacceptable consumers, weak peach wine flavor and weak aroma, and achieve the effects of unique peach wine flavor, mellow wine aroma and fruity aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

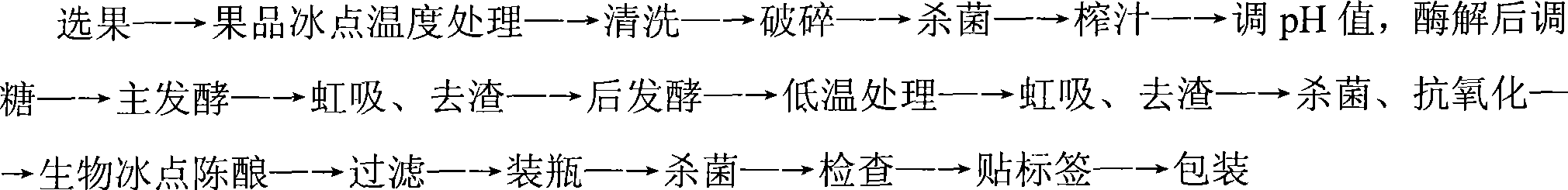

Method used

Image

Examples

Embodiment 1

[0025] Example 1 dry peach wine

[0026] Brewing time: August 15, 2006

[0027] Raw materials: 200 kilograms of Huayu peach (Pinggu Dahuashan), and finished wine: 140 kilograms.

[0028] The operation is as follows:

[0029] Fruit selection, Huayu peach (Pinggu Dahuashan) 200 kg —→ Biological freezing point treatment (store at -1°C for 5 days) —→ Wash and break, remove the core —→ Sterilize (add potassium metabisulfite: 30.5 grams), add fruit Enzymolysis of 16 grams of gelatinase (stirred at 40°C for 10 hours)—→Squeeze the juice, adjust the pH value to 3 (the amount of tartaric acid is about 108 ml), and then adjust the sugar (the amount of sugar added is 16.5 kg)—→Main fermentation for 6 days (add dry 36 grams of yeast, fermentation temperature 10-15°C) —→ pour the bucket, remove the sediment at the bottom of the fermenter (siphon method can be used) —→ post-fermentation for 30 days (fermentation temperature is 15-18°C) —→ -4°C low temperature Stand still for 5 days—→pour ...

Embodiment 2

[0031] Brewing time: August 30, 2006

[0032] Raw materials: 200 kilograms of Jingyu peach (Pinggu Dahuashan), 20 kilograms of Muscat grapes as ingredients, and 142 kilograms of finished wine.

[0033] The operation is as follows:

[0034] Fruit selection, 200 kg of Huayu peach (Pinggu Dahuashan) and 20 kg of muscat grapes (purchased at Nongda Supermarket)—→biological freezing point treatment (stored at -1.4°C for 7 days)—→cleaning and crushing—→sterilization (potassium bisulfite Dosage: 40 grams), add 18 grams of pectinase (stir at 45°C for 15 hours)—→ squeeze the juice—→ adjust the pH value to 3 (the amount of tartaric acid is about 100 ml), and then adjust the sugar (the amount of sucrose is 15 kg)—→ main Ferment for 6 days (40 grams of dry yeast, fermentation temperature is 10-15°C)—→filter, remove slag—→add 8 grams of sulfur dioxide, which has the functions of sterilization, clarification and color protection, and post-fermentation for about 25 days (15-18 ℃), stop ferm...

Embodiment 3

[0035] Embodiment 3, semi-sweet peach wine

[0036] Brewing time: October 15, 2007

[0037] Raw materials: 200 kilograms of Zhonghuashou Tao (Pinggu), and 138 kilograms of finished wine.

[0038] The operation is as follows:

[0039] Fruit selection, 200 kg of Zhonghuashou Tao (Pinggu) —→ Biological freezing point treatment (storage at -1.5°C for 7 days) —→ Washing and crushing —→ Sterilization (dosage of potassium metabisulfite: 30 grams), plus 15 grams of pectinase (50 Stirring at ℃ for 20 hours) —→ squeeze the juice —→ adjust the pH value to 3.5 (the amount of lactic acid is about 108 ml), then adjust the sugar (the amount of sucrose is 15 kg) —→ main fermentation for 5 days (dry yeast 36 grams, fermentation temperature 10-15 ℃)—→filter, remove slag—→add 10 grams of sulfur dioxide, which has the effects of sterilization, clarification and color protection, (fermentation temperature is 15-18 ℃), stop fermentation when the fermentation residual sugar is 14 grams / liter—→- S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com