Production method of television line diagram for testing photoelectronic imaging system resolution power

A photoelectric imaging and production method technology, which is applied in the direction of testing optical performance, optical instrument testing, machine/structural component testing, etc., and can solve the problems of high cost, unsatisfactory, and inability to meet the needs of higher and higher pixels for special charts, etc. , to achieve the effect of good versatility, avoiding Chart usage and distribution errors, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

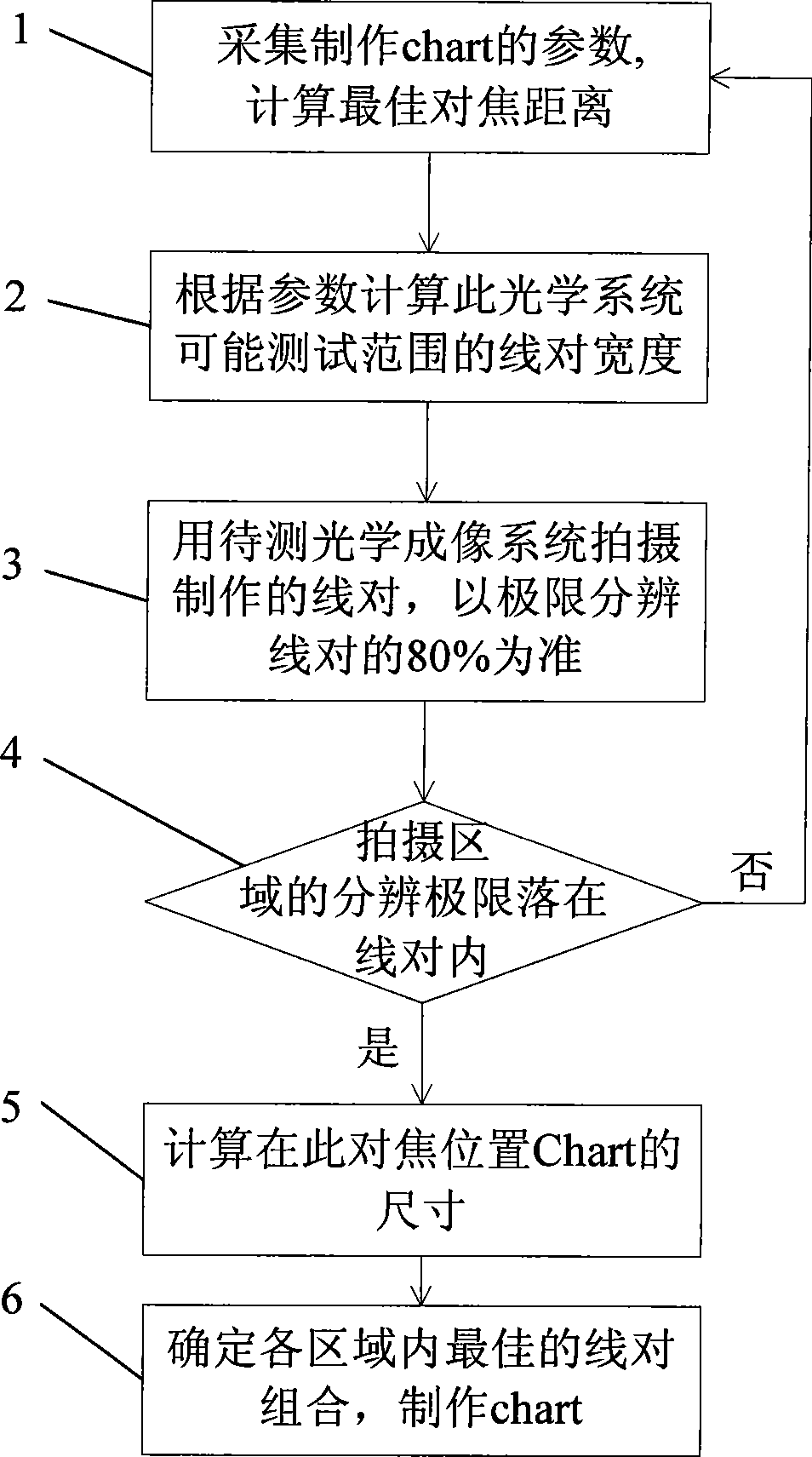

Method used

Image

Examples

Embodiment 1

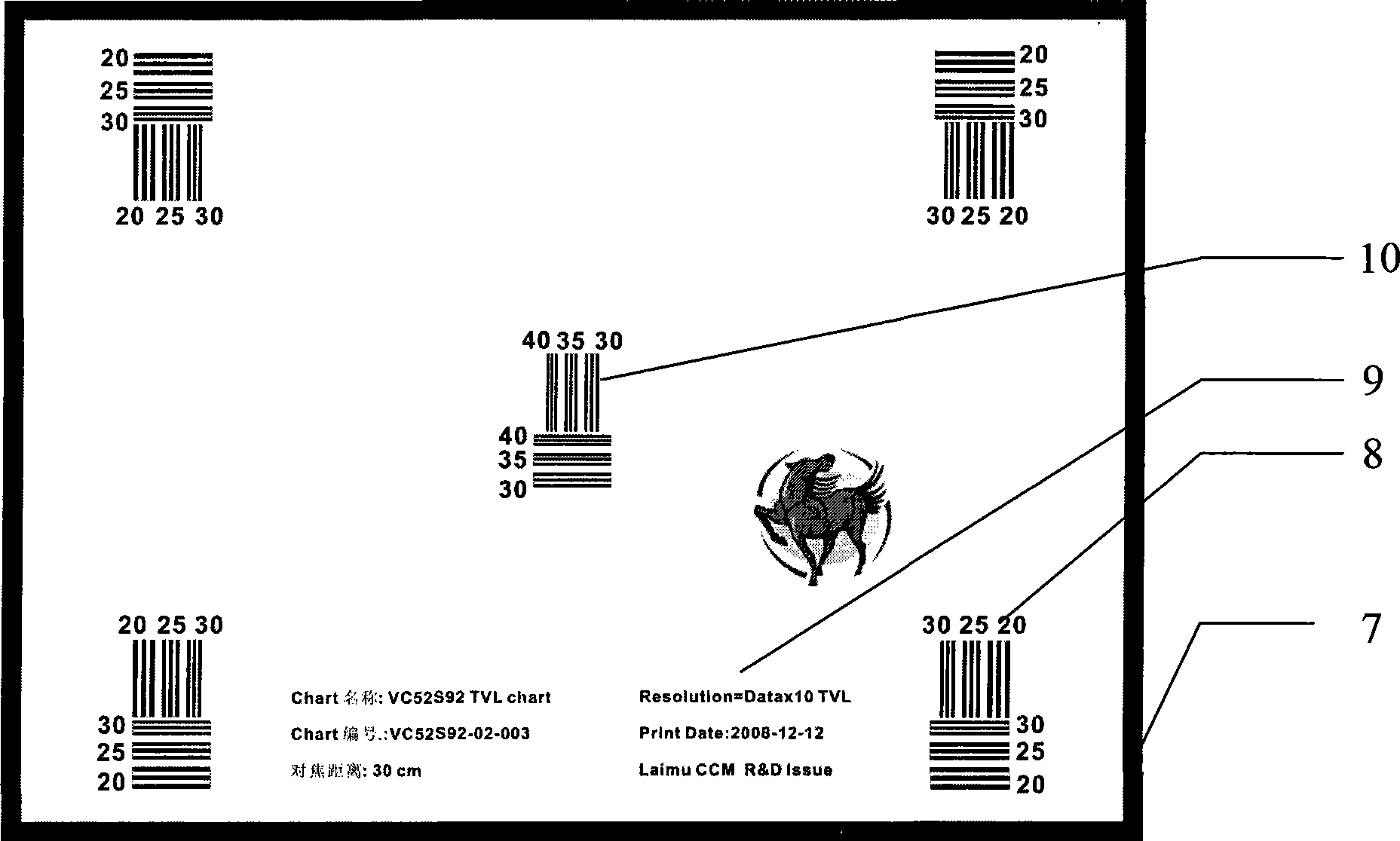

[0056] Parameters related to chart design:

[0057] CMOS Sensor parameters: pixel array: 640 x 480; pixel size: 3.0um

[0058] Lens parameters: F / No.=2.8; EFL=1.96mm

[0059] For the optimal imaging distance and line width of all levels of this photoelectric imaging system:

[0060] Best focusing distance: 30cm;

[0061] Line width:

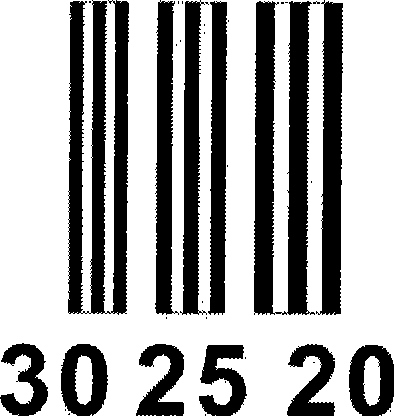

[0062] 400TVL: 0.5474mm

[0063] 350TVL: 0.6256mm

[0064] 300TVL: 0.7299mm

[0065] 250TVL: 0.8759mm

[0066] 200TVL: 1.095mm

[0067] Take pictures of the pair clusters to determine if the pairs and the pair clusters are arranged properly:

[0068] Photographs taken of line-pair clusters in the central area:

[0069] The central 400TVL line pair cannot be clearly distinguished, the 350TVL line pair can be distinguished, and the 300TVL line pair can be clearly distinguished. It shows that the line pair selection is reasonable and the line pair cluster arrangement is correct;

[0070] 0.7 field of view area line-to-cluster shooting pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com