Dredging synthetic platform management system of trail suction dredger based on redundancy network

A trailing suction dredger and platform management technology, which is applied in the transmission system, electrical components, comprehensive factory control, etc., can solve the problems of equipment safety accidents, dredgers cannot be constructed normally, and redundant performance is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

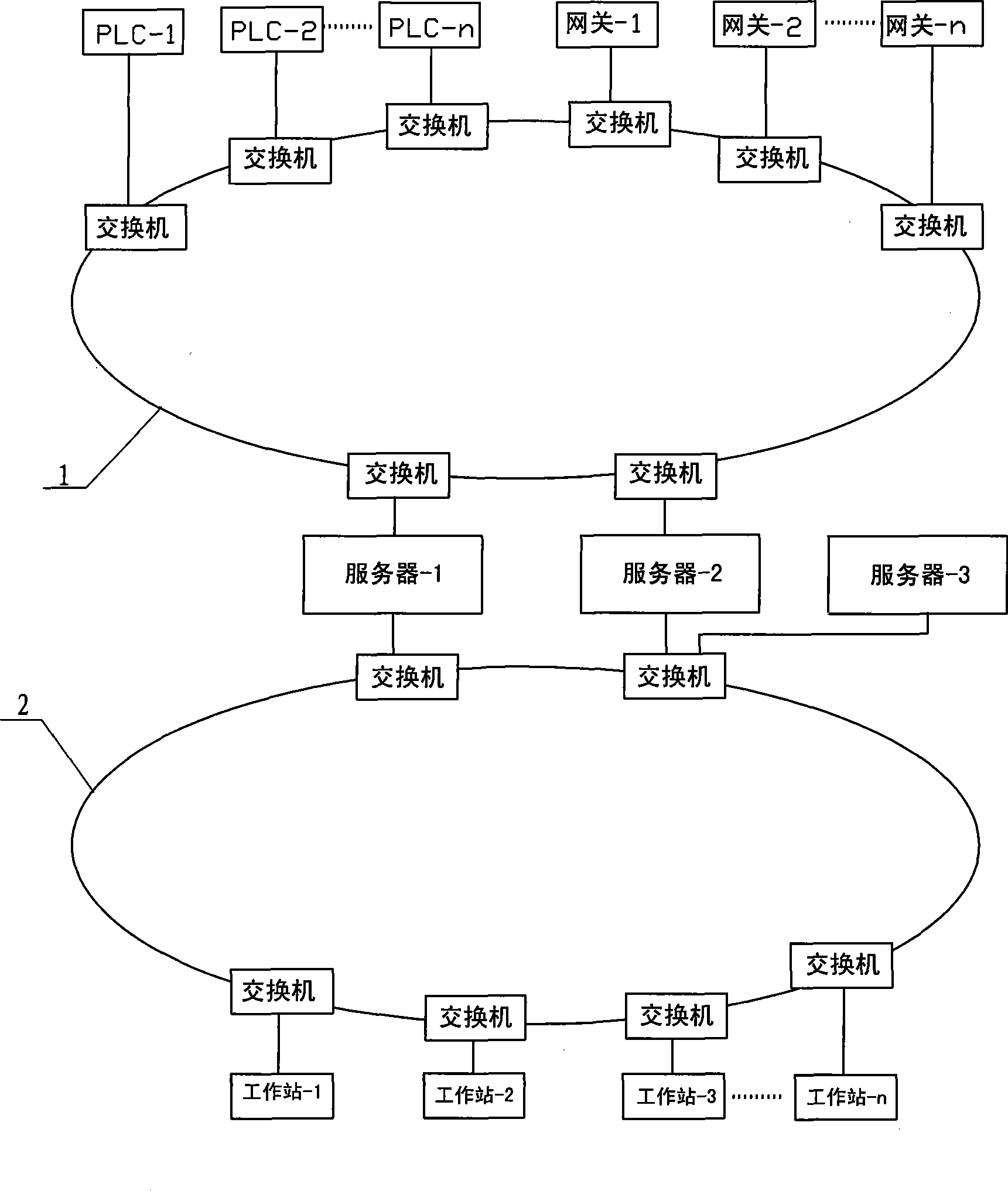

[0010] figure 1 The integrated dredging platform management system for trailing suction dredgers based on redundant networks shown in , uses two ring networks, the bottom ring network 1 is responsible for bottom data collection, the top layer ring network 2 is responsible for upper layer data monitoring, and data exchange at the field bus layer The data exchange with the monitoring layer of the computer workstation is independent and separated. Each ring network includes at least three network switches. The switches are industrial-grade network switches with at least 2 groups of optical fiber interfaces and 2 RJ45 interfaces. The optical fiber interfaces are ST or SC. , RJ45 interface is 10Mb / 100Mb adaptive, with independent IP, DC24V dual power supply, with alarm output, DIN rail installation, working temperature at least -10 ℃ ~ 65 ℃. The number of switches depends on the number of PLCs, gateways, and workstations.

[0011] A total of three servers are connected between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com