Hollow platelet heat exchangers

A heat exchanger, hollow technology, applied in heat exchange equipment, heat exchanger type, indirect heat exchanger, etc., can solve the problem of low thermal resistance, achieve high hardness and elastic limit, prevent contact, and increase inertial motion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

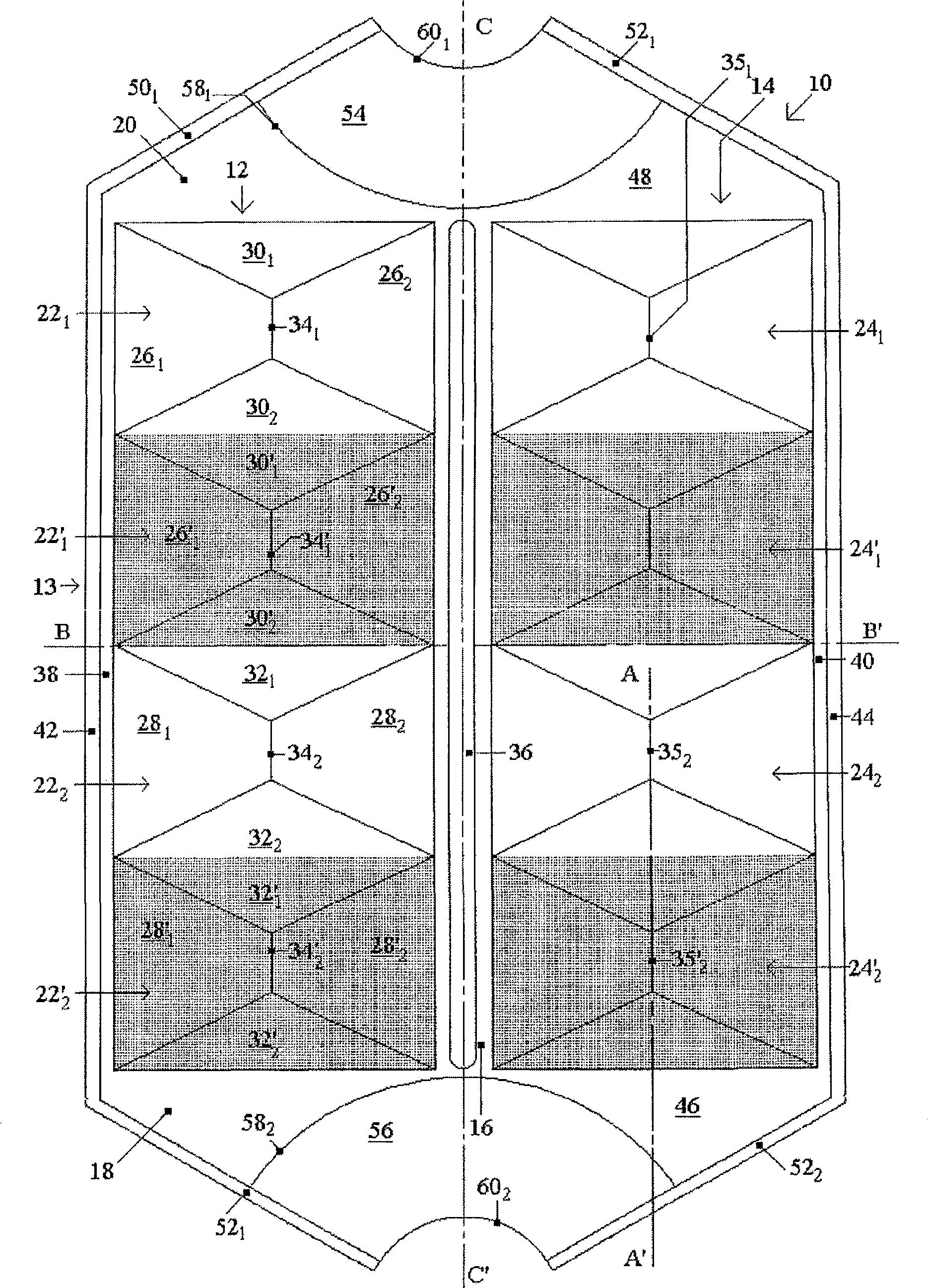

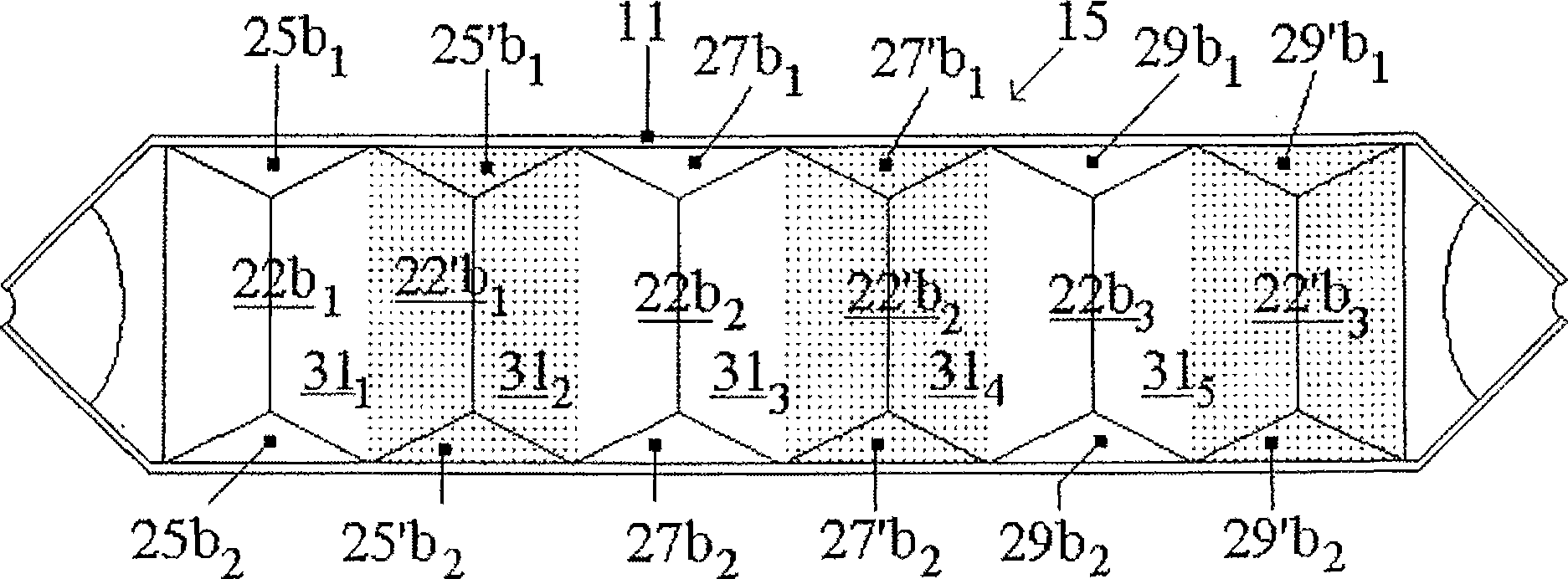

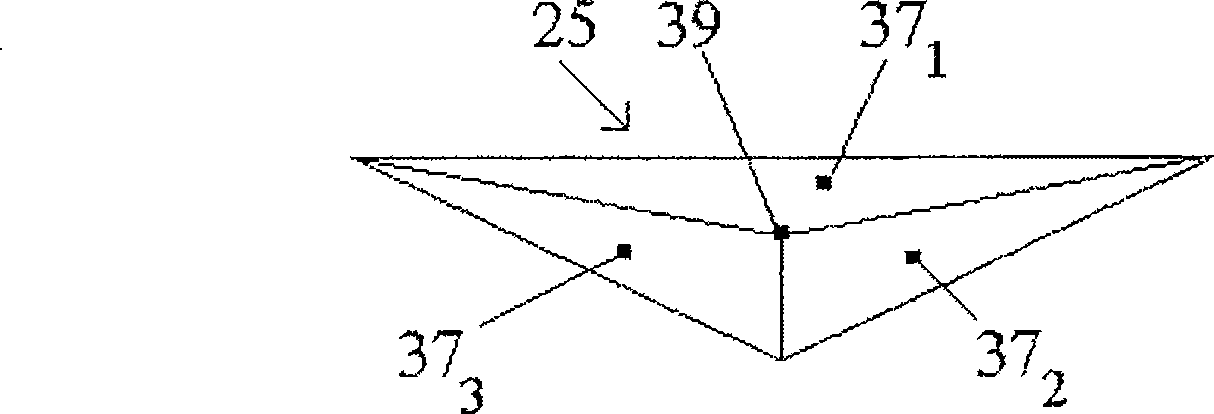

[0067] figure 1A first embodiment of a thin metal wall portion 10 of a hollow plate is shown. The wall is stamped and subsequently cut to have a stamped central region 13 disposed between two connecting regions. As an example, the wall is made of aluminum, 0.3 mm thick, and its molded central region is 60 mm wide and 76 mm long. The central region 13 is formed by two adjacent alternating protrusions 12 and 14 of the same row separated by a narrower straight region 16 of width 4 mm. The two connecting regions 18 and 20 have smooth walls. Each row comprises two identical alternating embossed areas (areas) consisting of protrusions and recesses, i.e. rows 12-14 have on the one hand four protrusions 22 1-2 and 24 1-2 On the other hand there are four recesses 22' 1-2 and 24' 1-2 , where the latter is shown in gray. Each protrusion 22 1-2 -twenty four 1-2 Or each recess 22' 1-2 -twenty four' 1-2 Forms a roof shape like four slopes with four very steep sharp edges, i.e. f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com