Superfine mercerization Australian wool blended stocking yarn and processing technique thereof

A technology of Guangao wool blending and processing technology, which is applied in the field of wool spinning, can solve problems such as difficult technology, and achieve the effects of broad market prospects, cost reduction, and evenness and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

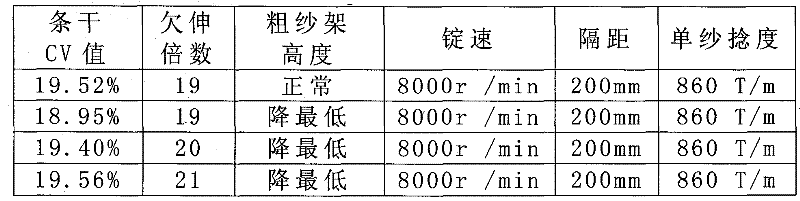

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the examples.

[0027] The superfine mercerized Australian wool blended knitting yarn of this scheme is 82NM / 2.

[0028] Raw material ratio: ultra-fine mercerized Australian wool 60%, fineness 15.6um;

[0029] Turkish mohair 40%, fineness 24um.

[0030] Present embodiment casts and spins 600 kilograms. The specific process is as follows:

[0031] (1), pre-spinning process:

[0032] ① The moisture regain time of the wool top is 24 hours, the temperature of the moisture regain chamber is 25±3°C, and the relative humidity is 80±5%, so that the moisture regain of the wool top reaches 24%.

[0033] ②In the upper combing machine (French GN6-17), wool tops are added with crude oil, so that the oil content of wool tops on the lower machine is 1%, and the ratio of the wool tops to crude oil is:

[0034] Antistatic agent: oil: water: cohesion enhancer = 0.5: 1: 8: 0.5;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com