Composite heat insulating walling and mounting method thereof

A composite thermal insulation and installation method technology, applied in thermal insulation, walls, building components and other directions, can solve the problems of environmental pollution, manpower and material resources, long construction period, etc., to achieve the effect of reducing costs, saving materials, and low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

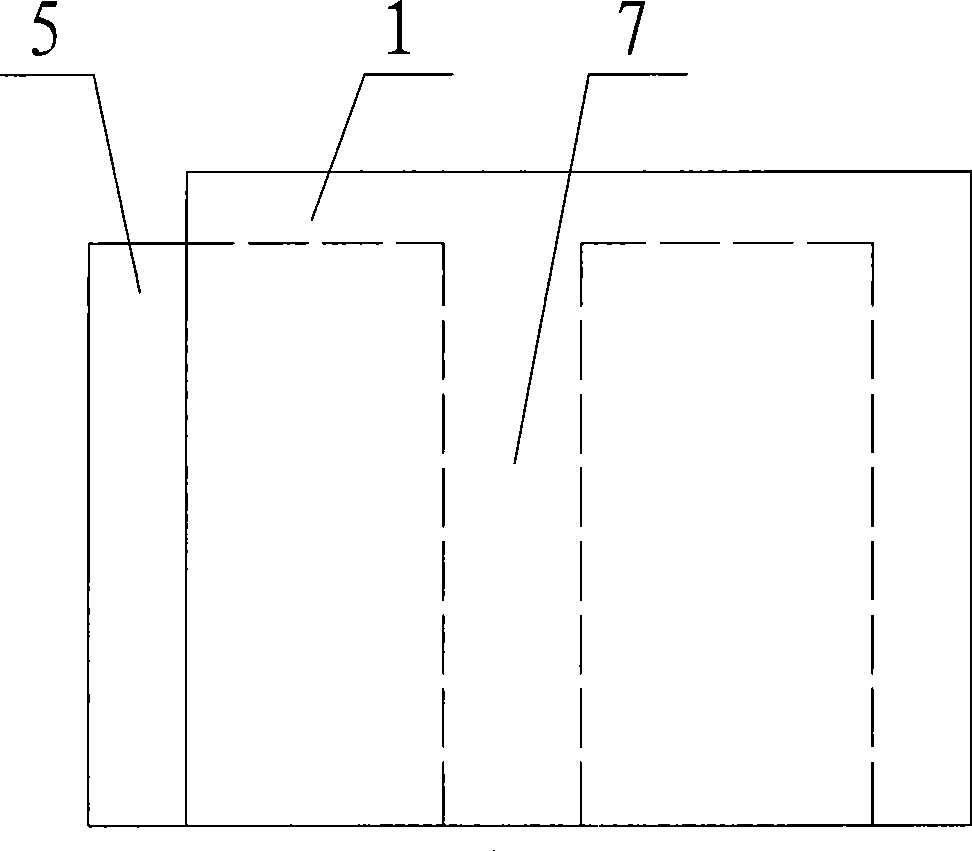

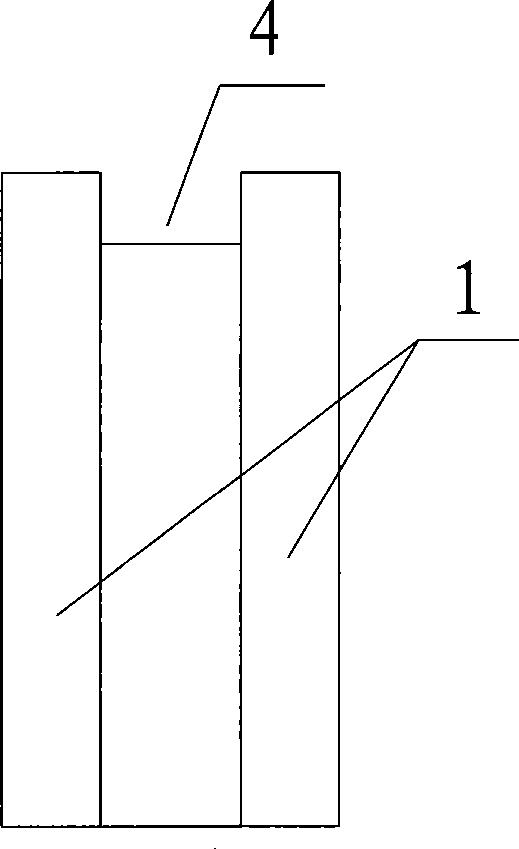

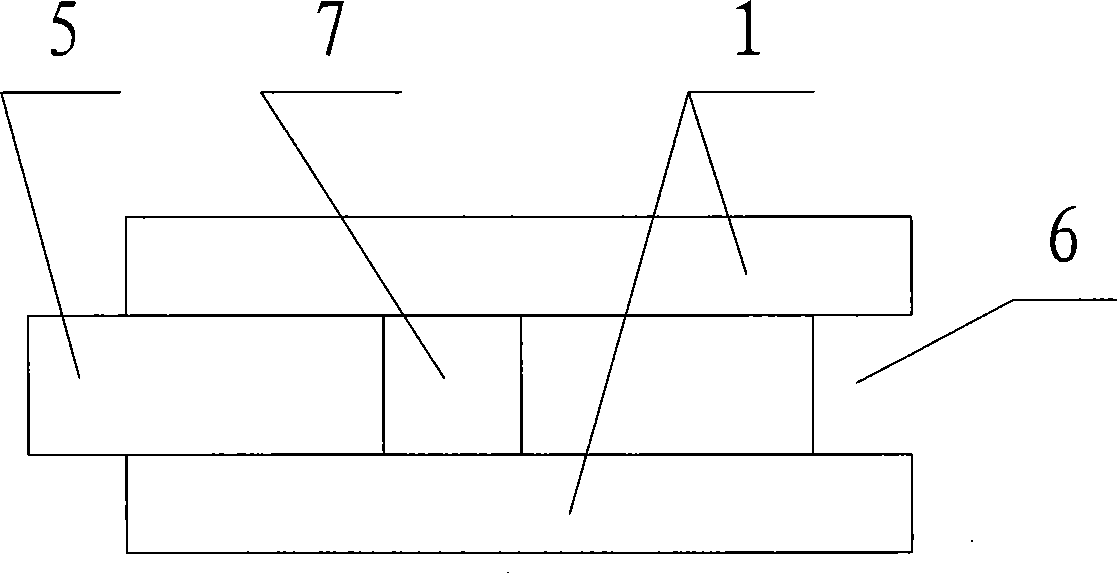

[0032] Such as Figure 1-9 As shown, the composite thermal insulation wall body of the present invention includes EPS (polystyrene) board 1, column reinforcement 2 and beam reinforcement 3 pre-embedded on the foundation. One side of the EPS board 1 is provided with a first concave groove 4, and the symmetrical two sides adjacent to this side are respectively provided with a boss 5 extending out of the board and a second concave groove 6 opened in the board, the boss 5 and the second The shape and size of the concave grooves 6 are the same for two EPS boards to be plugged together during installation. On the EPS board 1 between the boss 5 and the second concave groove 6, a hole 7 for accommodating the column steel bar 2 is provided along the length direction of the board. The radial cross section of the hole 7 can be square or circular. In this embodiment is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com