Flat minitype pump

A micro-pump, flat technology, applied in the field of flat micro-pumps, can solve problems such as poor motor cooling capacity, low fluid outlet pressure, low output torque, etc., to reduce service life shortening, improve torque and fluid outlet pressure, structure tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to have a further understanding of the purpose, structural features and functions of the present invention, a detailed description is given in conjunction with relevant embodiments and drawings as follows:

[0039] Please refer to figure 1 , which is a schematic diagram of a flat micropump according to the first embodiment of the present invention. The flat micropump 10 of the first embodiment of the present invention is applied to the delivery of a fluid (not shown in the figure), which can be coolant in a water-cooled heat dissipation system, fuel used in a fuel cell, or blood delivered by an artificial heart Wait.

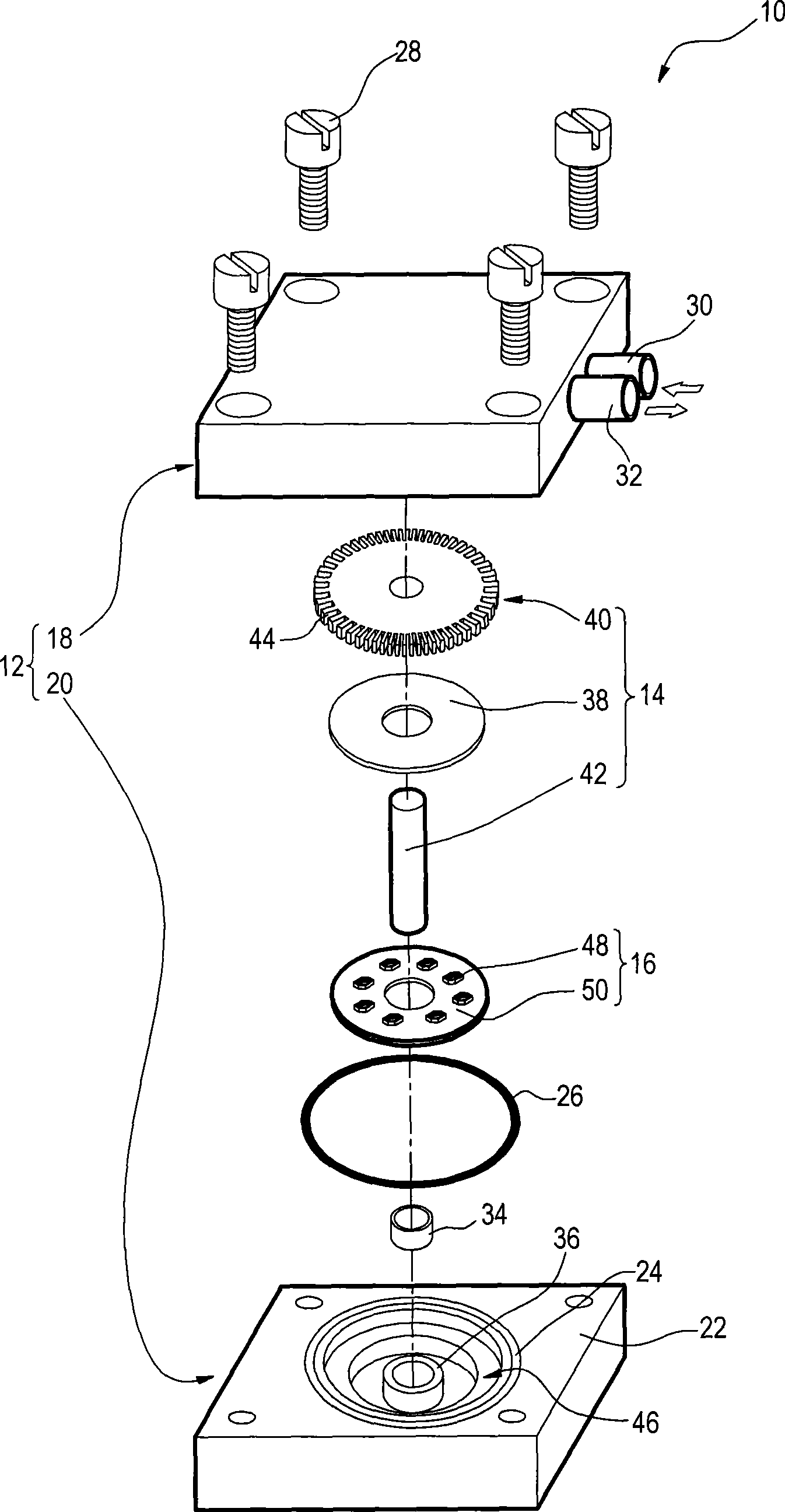

[0040] Please refer to figure 2 , which is a component diagram of the flat micropump according to the first embodiment of the present invention. The flat micropump 10 according to the first embodiment of the present invention mainly includes a main body 12 , a rotor 14 and a stator 16 . The main body 12 includes a cover portion 18 and a bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com