Rotatable blade for face milling and processing

A technology of face milling and indexing inserts, applied in milling cutters, metal processing equipment, manufacturing tools, etc., can solve the problems of decreased machining vertical surface accuracy, affecting the quality of the machined surface, large difference, etc., to improve the cutting angle strength and strength. Enhanced, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

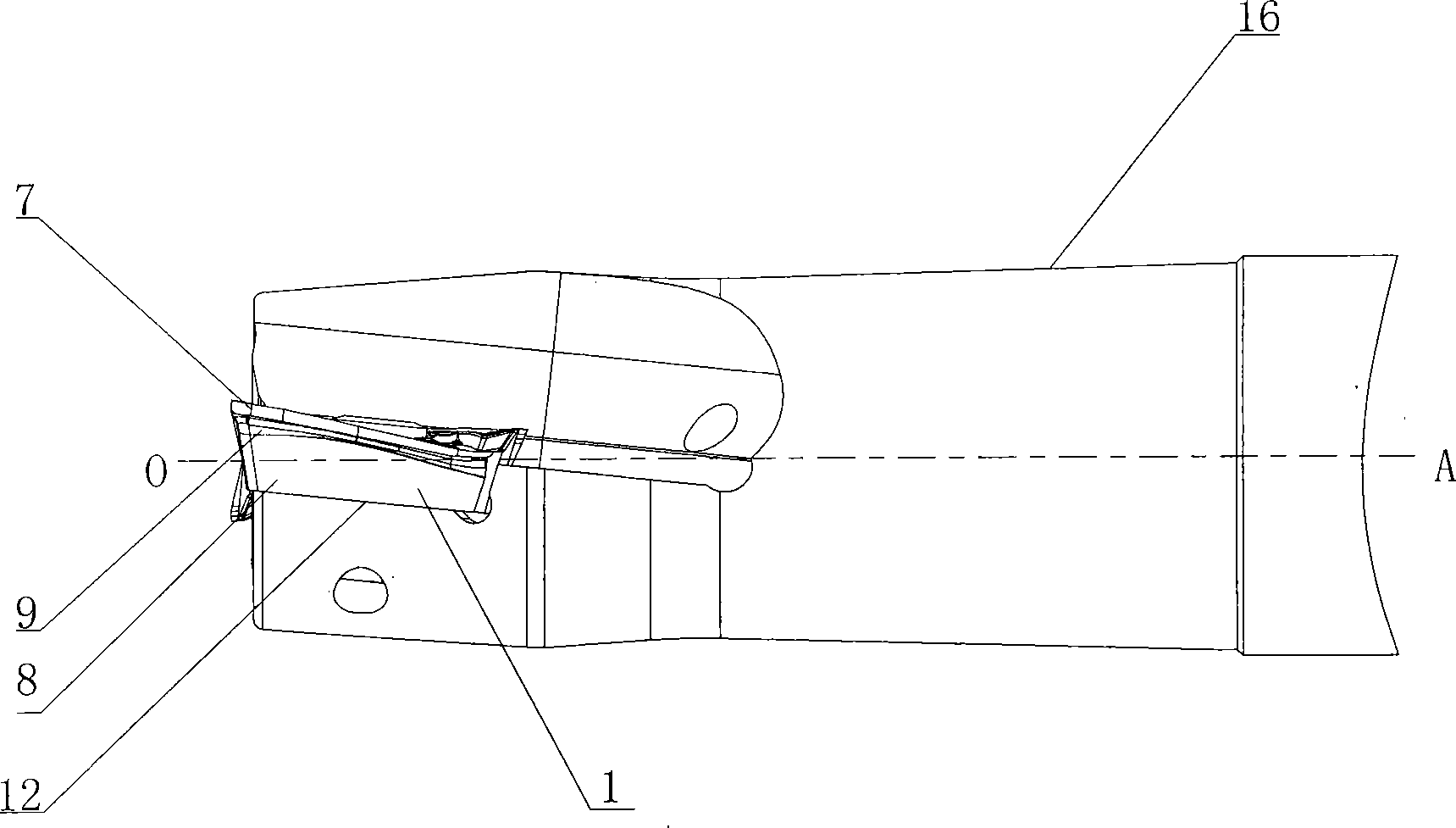

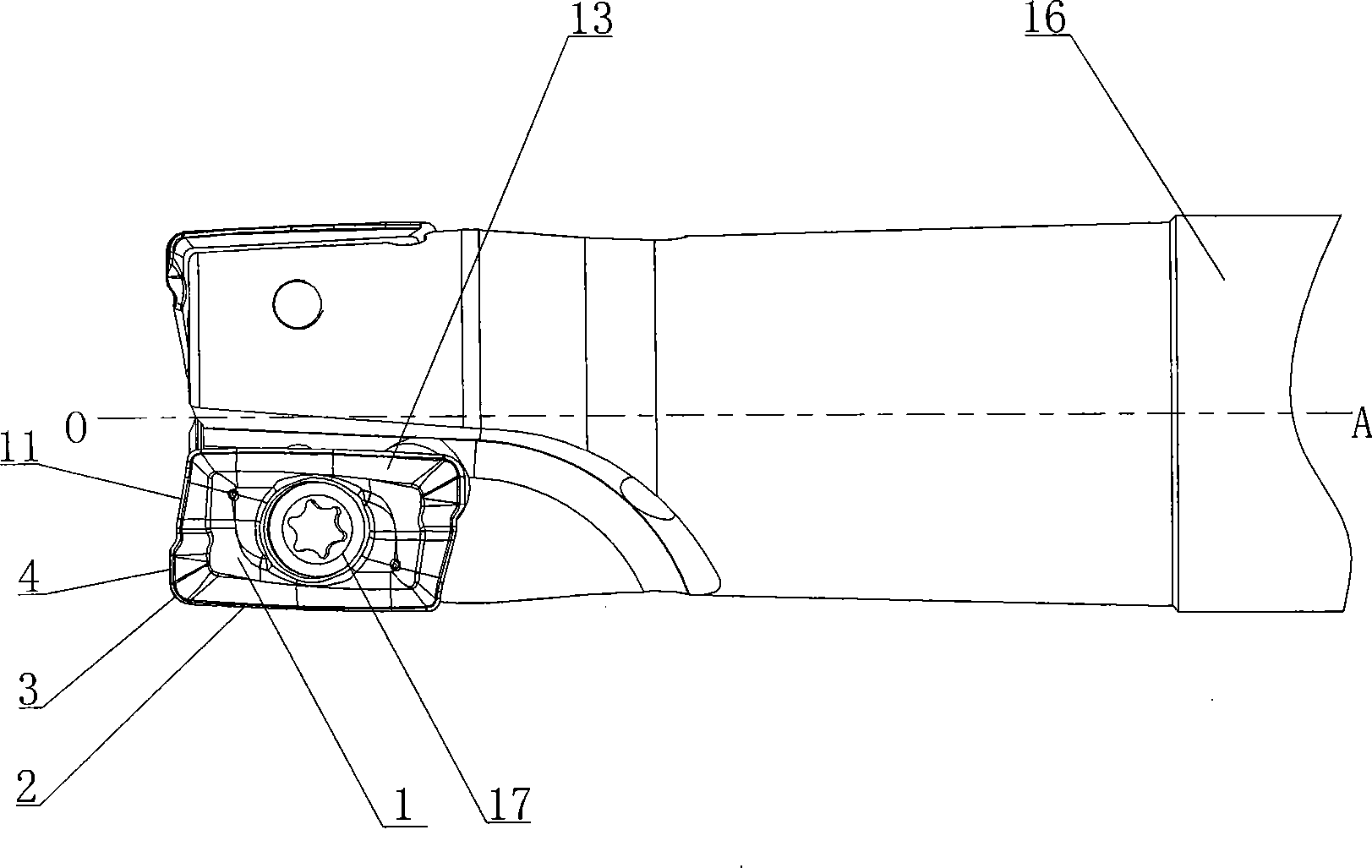

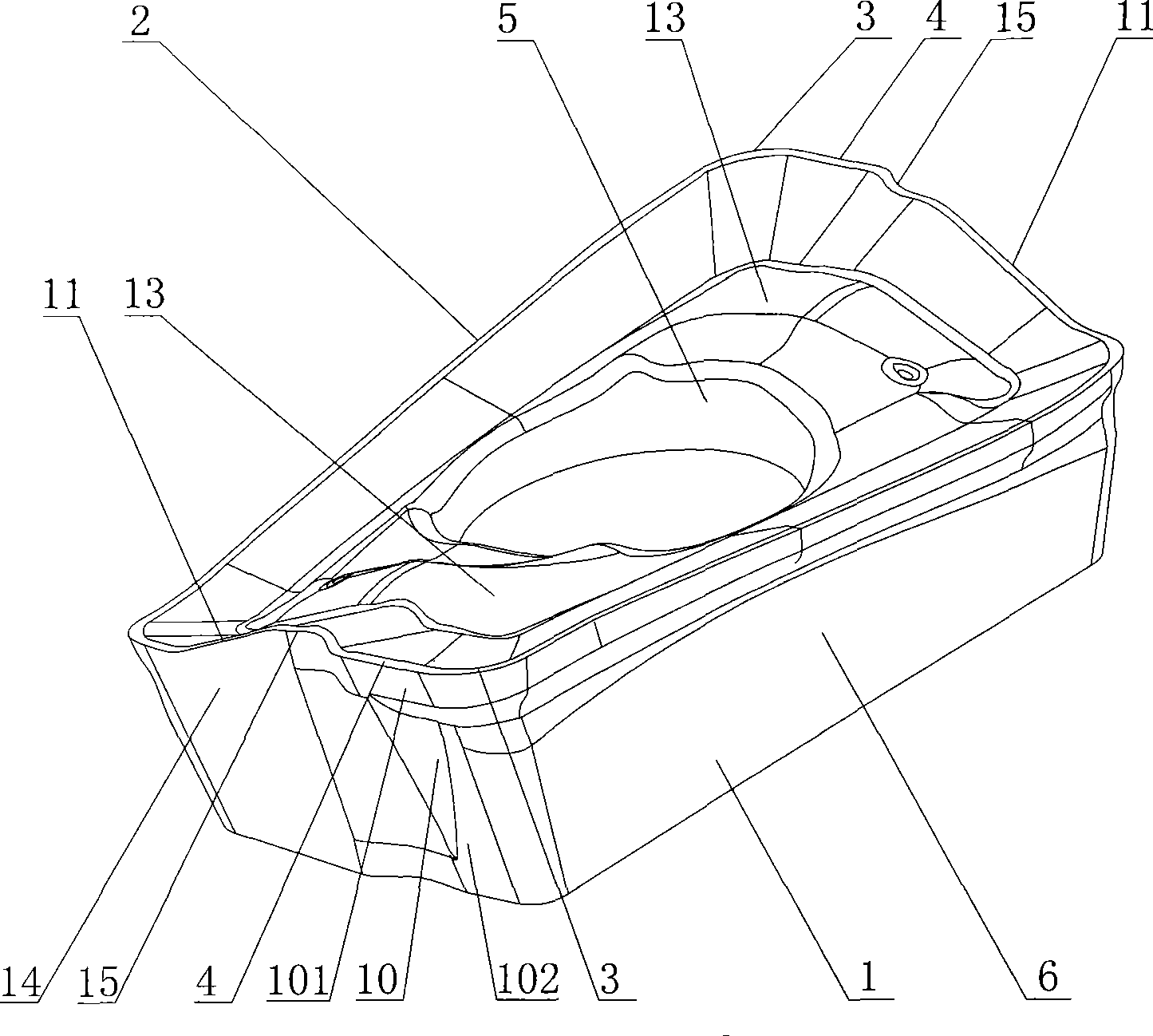

[0034] Such as Figure 3 to Figure 8 As shown, the indexable insert for face milling of the present invention includes an insert body 1 surrounded by an upper surface 13, a lower bottom surface 12, two end surfaces 14 connecting the upper and lower bottom surfaces, and two side surfaces 6. The insert body 1 It is formed by pressing cemented carbide powder, and then sintering and shrinking at high temperature in a special sintering equipment. The center of the blade body 1 is provided with the blade center hole 5 perpendicular to the bottom surface 12 of the blade, and the intersection line between the upper surface 13 of the blade body 1 and the two side faces 6 forms a pair of main cutting edges 2, and the upper surface 13 of the blade body 1 and the The intersecting lines of each end face 14 all form the wiper edge 4 and the minor cutting edge 11, and the wiper edge 4 and the minor cutting edge 11 are connected by a recessed part 15, which can reduce the minor cutting edge 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com