Security induction valve and security buffering two-purpose valve employing the same

A safety and valve body technology, applied in the direction of machines/engines, etc., can solve the problems of insensitive safety valve response, inability to effectively relieve pressure, and high cost, and achieve the effects of simple structure, extended service life, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

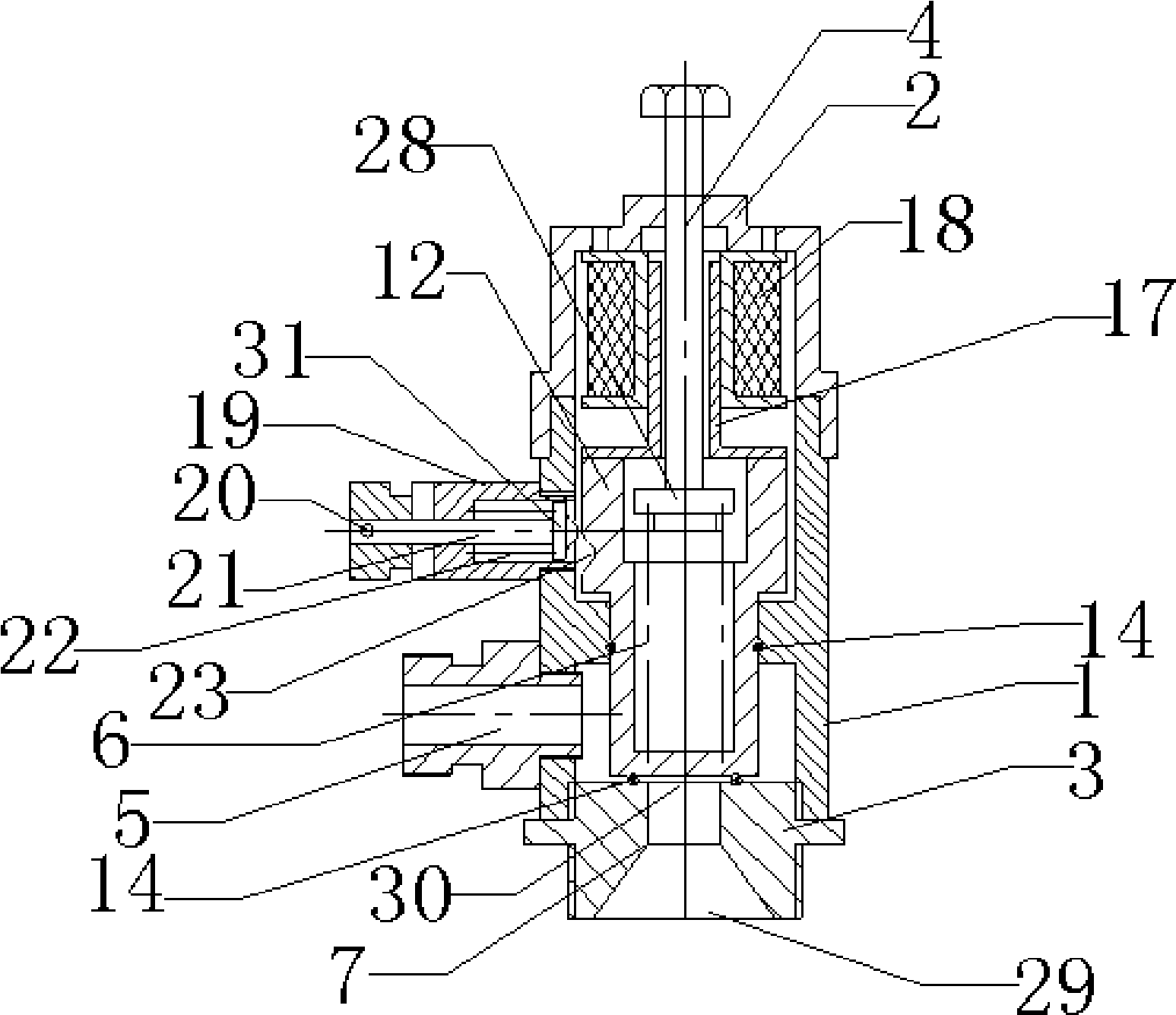

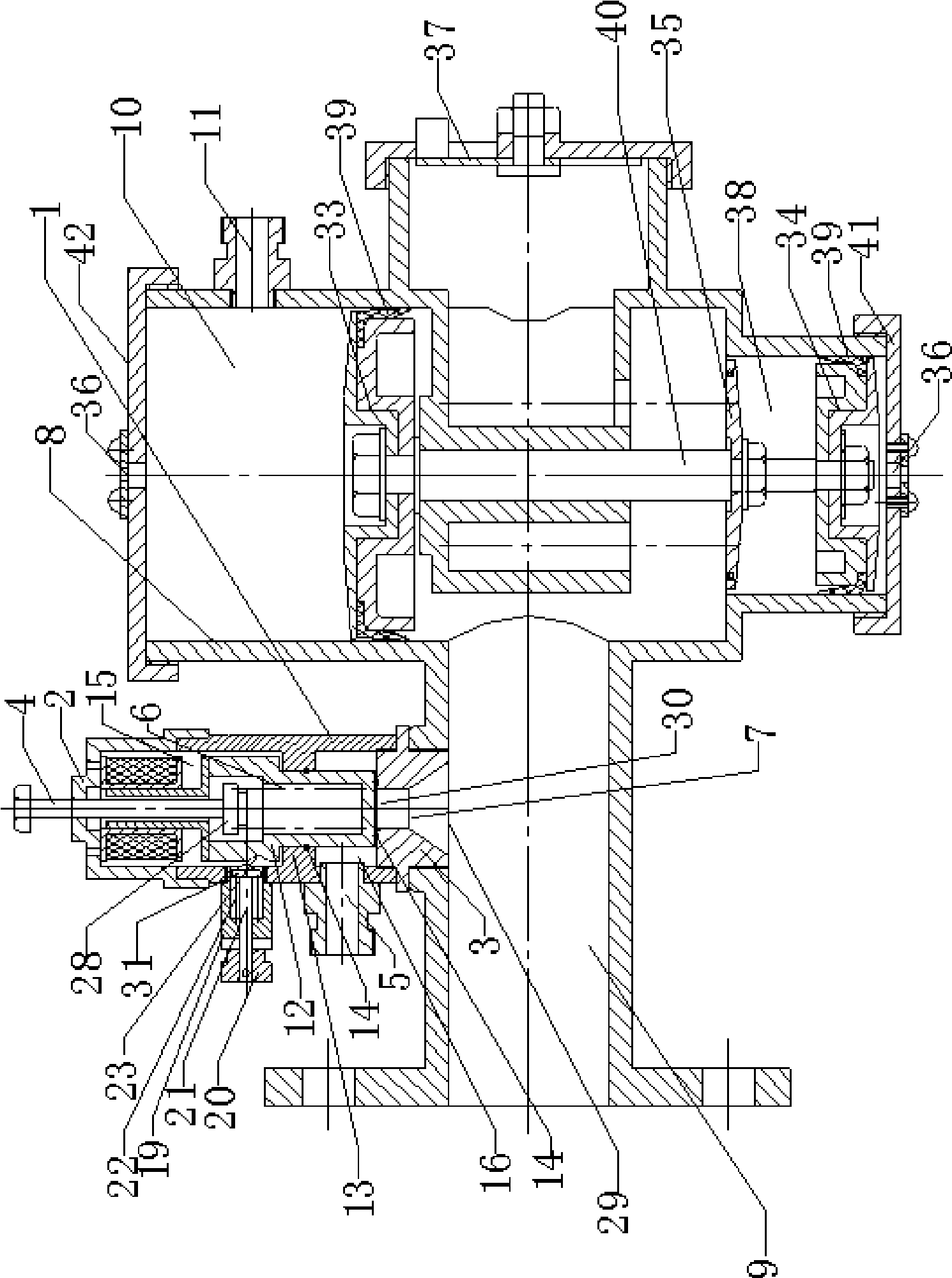

[0042] Such as figure 1 and 2 As shown, the safety buffer dual-purpose valve of the present invention includes a safety buffer dual-purpose valve body 8, a safety induction valve, a large piston 33, a small piston 34, an opening and closing valve plate 35, a damping hole 36, and an initial pressure regulating valve plate 37 And the upper valve cover 42, the safety induction valve is located at the entrance of the valve body 1 pipeline 9, the large piston 33, the small piston 34, and the opening and closing valve plate 35 in the valve body 1 are connected and fixed by the connecting shaft 40, and the large piston 33 connects the valve body 1 is divided into an upper air chamber 10 and a lower air chamber 38. The pipe joint 11 on one side of the upper air chamber 10 communicates with the joint head 5 of the safety induction valve through a pipe. The bonnet 42 is fixed on the upper part of the valve body 1, the upper bonnet 42 is provided with a damping hole 36 in the center, th...

Embodiment 2

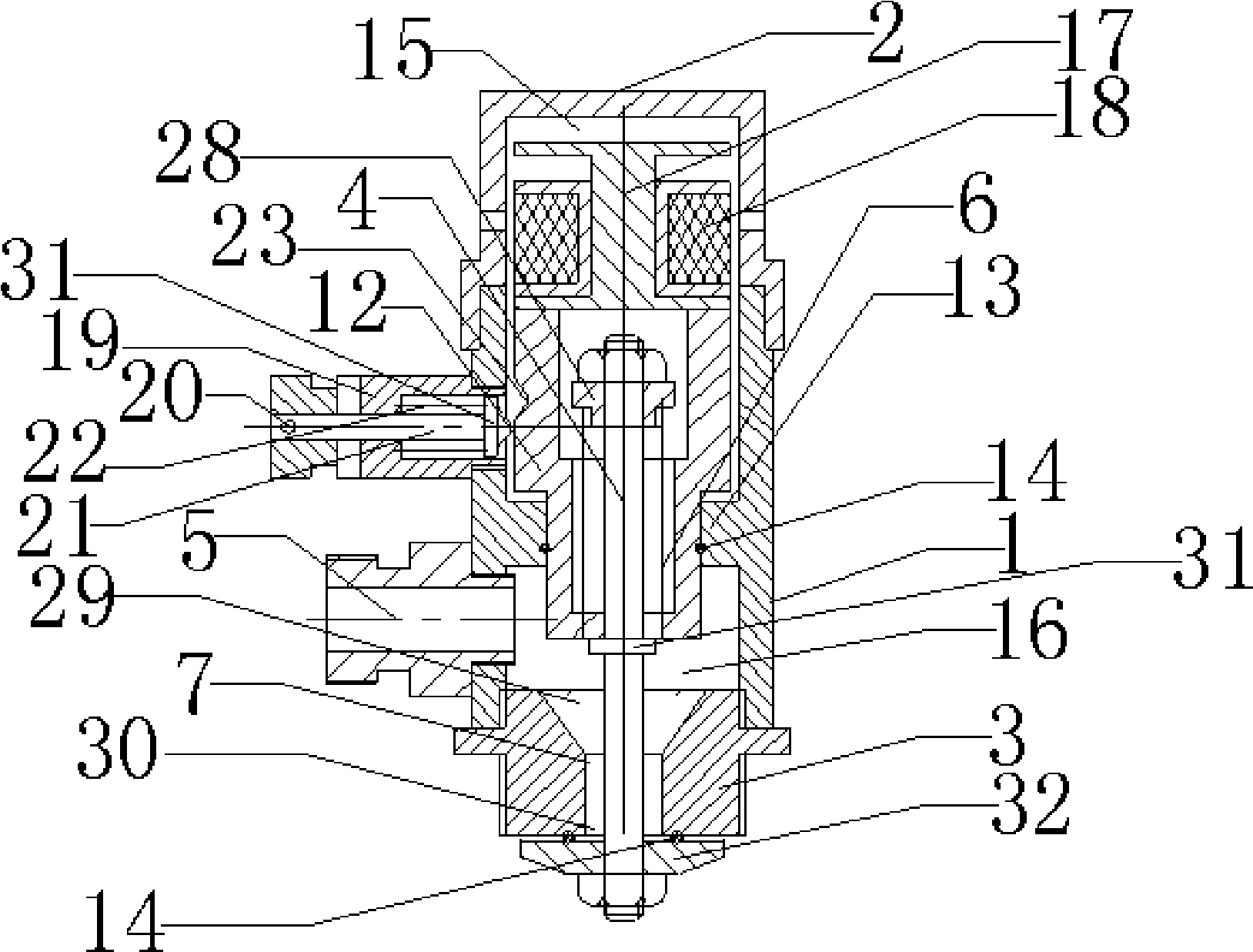

[0044] Such as image 3 and 4 As shown, the electromagnetic valve coil 18 and the electromagnet 17 of the safety induction valve in the vacuum state are fixed on the upper end surface of the valve core 12, and there is a gap between the electromagnetic valve coil 18 and the upper end of the electromagnet 17, and the pressure adjustment mechanism of the safety induction valve includes adjustment bolts 4 , spring 6, spring seat 28, snap ring 31 and valve plate 32, one end of adjusting bolt 4 sleeved with spring 6 is provided with spring seat 28, spring 6 is fixed between spring seat 28 and the bottom of spool 12, adjusting bolt 4 Passing through the bottom of the valve core 12 and the valve seat port 7, the snap ring 31 of the adjusting bolt 4 is located in the lower cavity 16, and the other end of the adjusting bolt 4 is fixed with a valve plate 32. Valve seat 3 is provided with valve seat port 7, and valve seat port 7 is made up of large port 29 and small port 30, and the end...

Embodiment 3

[0046] Such as Figure 5 , 6 , 7 and 8, a manual unloading mechanism is provided on the side wall of the valve body 1 corresponding to the safety induction valve locking device, and the manual unloading mechanism includes an unloading lever 25 and a base 26 with a handle 24, and The spool 12 on the corresponding side of the base 26 is provided with an unloading hole 27, and the axial width of the unloading hole 27 is equal to the up and down travel distance of the spool 12. Other structures of the safety induction valve and the structure of the dual-purpose safety buffer valve are the same as those in Embodiment 1, 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com