Low-temperature liquid vaporization cooling capacity recovery utilization system

A low-temperature liquid and cold energy recovery technology, used in applications, household appliances, household refrigeration devices, etc., can solve problems such as energy waste, and achieve the effect of extending service life, ensuring stability and vaporization capacity, and stable working temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

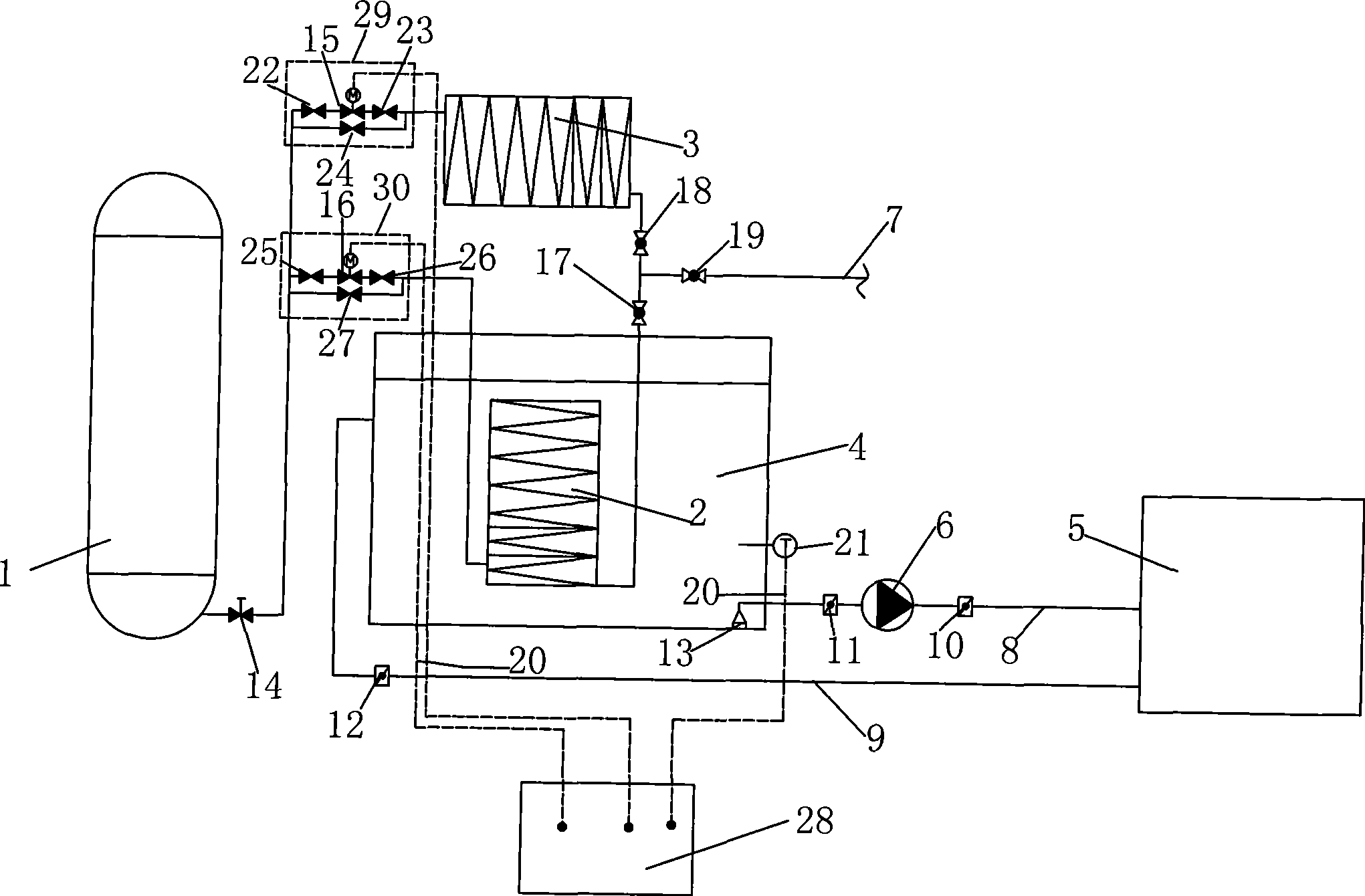

[0009] See figure 1 , the vaporization cold recovery system of the present invention comprises a water bath type vaporizer 2, an empty bath type bypass vaporizer 3, a water tank 4, a circulating water pump 6, a valve, a water supply pipeline 8 and a return water pipeline 9, the vaporizer 2 and the bypass vaporizer 3 Connected in parallel, the suction port 13 of the circulating water pump 6 in the water supply pipeline 8 is set at the low point of the water tank 4, the suction port 13 is trumpet-shaped, and the interface from the return water line 9 to the water tank 4 is set at the opposite high point of the suction port 13, Low-temperature electric valves 15 and 16 are respectively installed at the front ends of the carburetor 2 and the bypass carburetor 3, and the temperature sensor 21 is installed near the suction port of the circulating water pump 6. The low-temperature electric valves 15, 16 and the temperature sensor 21 realize the connection of the three through the auto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com