One-way fixed float valve plate

A float valve tray and tray technology, which is applied in the field of structural improvement of fixed float valve trays, can solve the problems such as the inability to completely solve the phenomenon of spraying and backmixing, and achieve the characteristics of good liquid flow distribution, easy processing and high separation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

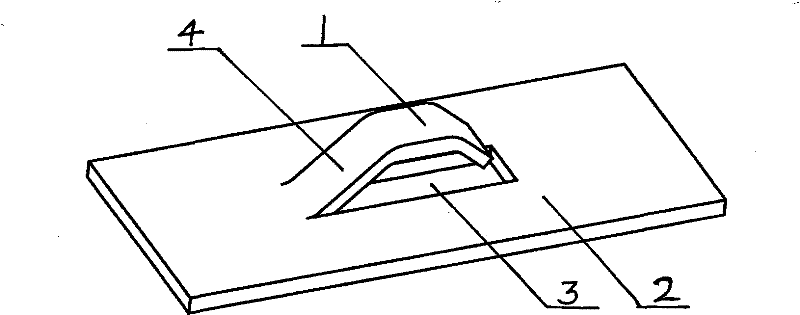

[0022] The methanol-water rectification system adopts the one-way fixed valve tray of the present invention to transform the original fixed valve tray. The number of trays is 30, the diameter of the tower is 2400mm, the spacing between the plates is 450mm, the opening rate of the tray is 7.8%, the material is stainless steel, and the float valves are arranged in the forward direction of the regular triangle. The valve plate is rectangular, the length of the valve hole is 50mm, and the width is 20mm. The side view of the valve plate is a bottomless trapezoid. The angle between the valve leg and the plate plane is 30°. The position (front end) is 5mm from the tray plate. After being put into operation, the processing capacity has been increased by 10%, and the pressure drop of the tray has been reduced by 5%. It has been running stably for 2 years now.

Embodiment 2

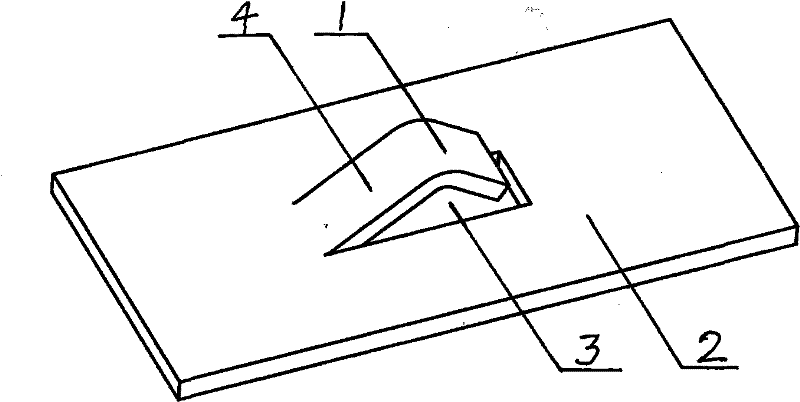

[0024] The rectification tower of a certain factory was reformed. The original 50-layer F1 float valve was used, and now it is changed to the one-way valve tray of the present invention. The tower diameter is 3200mm, and the plate spacing is 450mm. The opening ratio of the tray is 12.5%, and one-way fixed float valves are arranged on the tray, arranged in an isosceles triangle. The valve plate is diamond-shaped, the valve hole is 40m long and 15mm wide. The side view of the valve plate is a bottomless triangle. The angle between the valve leg and the plate plane is 30°. The position (front end) is 8mm from the tray plate. The intake air volume is 50000Nm3 / h. After the reconstruction of the rectification tower, the total separation efficiency is increased by 12%, the total pressure drop of the tray is reduced by 15%, and the phenomenon of pressure increase caused by dirty blockage during the original operation disappears.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com