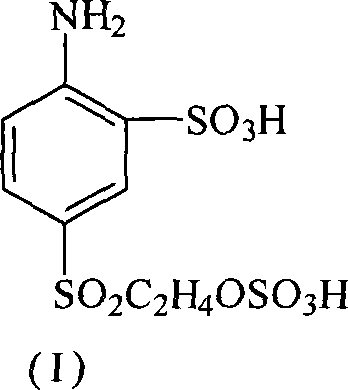

Comprehensive utilization method of sulphonation waste acid from sulphonation contraposition ester production process

A technology for the production process of sulfonated para-ester, applied in the direction of sulfonic acid preparation, sulfur trioxide/sulfuric acid, etc., can solve the problems of large waste of human resources, unacceptable environment, high incineration cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 20m of sulfonated waste acid produced in the sulfonation process in the production of PS (sulfonated para-ester) 3 Collect it into the recovery tank at 50°C through an acid-resistant pump, add 60kg of granular activated carbon to it, stir slowly and absorb for 3 hours, then pump it to the filter press for pressure filtration by the acid-resistant pump, and filter out the colorless dilute sulfuric acid clear liquid. The concentration is about 40%. This dilute sulfuric acid is used to adjust the pH value of the diazotization reaction in the production process of reactive dyes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com