Modularized bioreactor

A bioreactor, modular technology, applied in the direction of sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of difficult construction, inconvenient system maintenance, and difficult system expansion and reconstruction. Achieve simple and convenient operation and management, enhance continuous use performance, and facilitate standardization construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

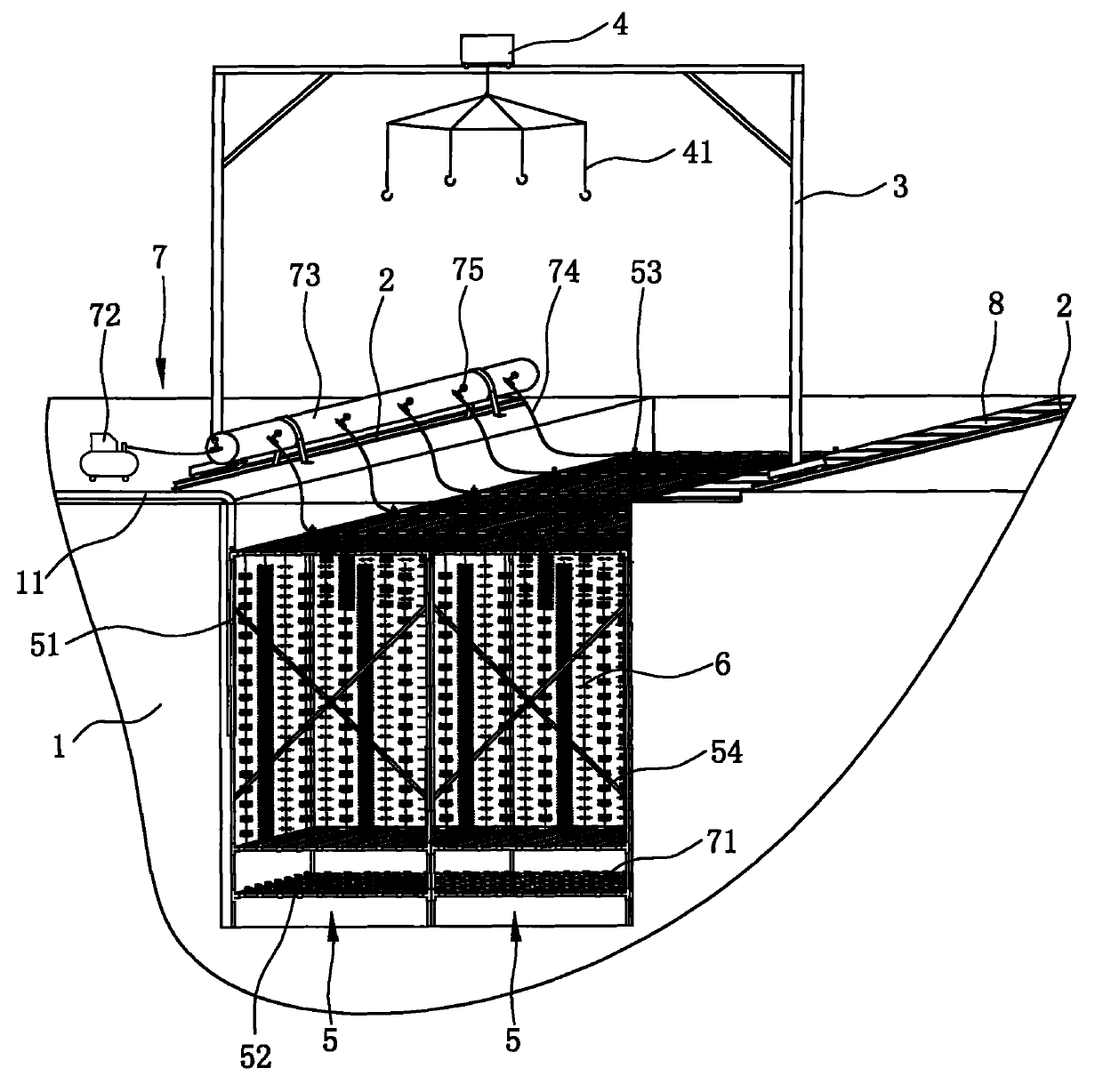

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

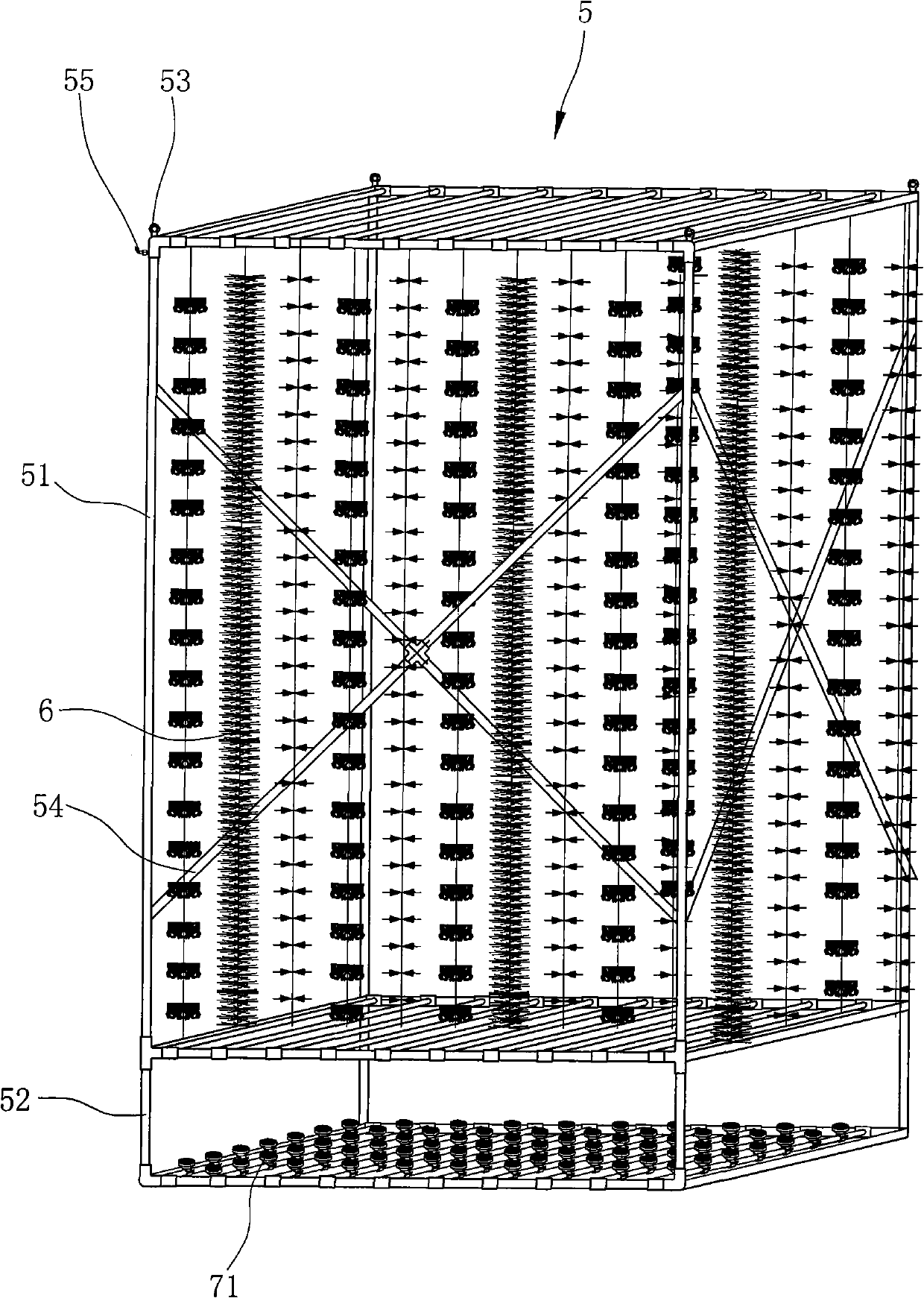

[0023] like Figure 1 ~ Figure 3 As shown, the modular bioreactor includes a pool body 1, a water inlet pipe 11 leading into the pool body 1, a pair of rails 2 arranged on the outer edges of both sides of the top of the pool body 1, erected on the pool body 1 The gantry support 3 whose bottom can move along the track 2, the mobile device 4 which is arranged on the top of the gantry support 3 and can move back and forth along the top of the gantry support 3, the hook 41 connected under the mobile device 4, and the aeration device 7 And the biological filler 6 in the pool body 1;

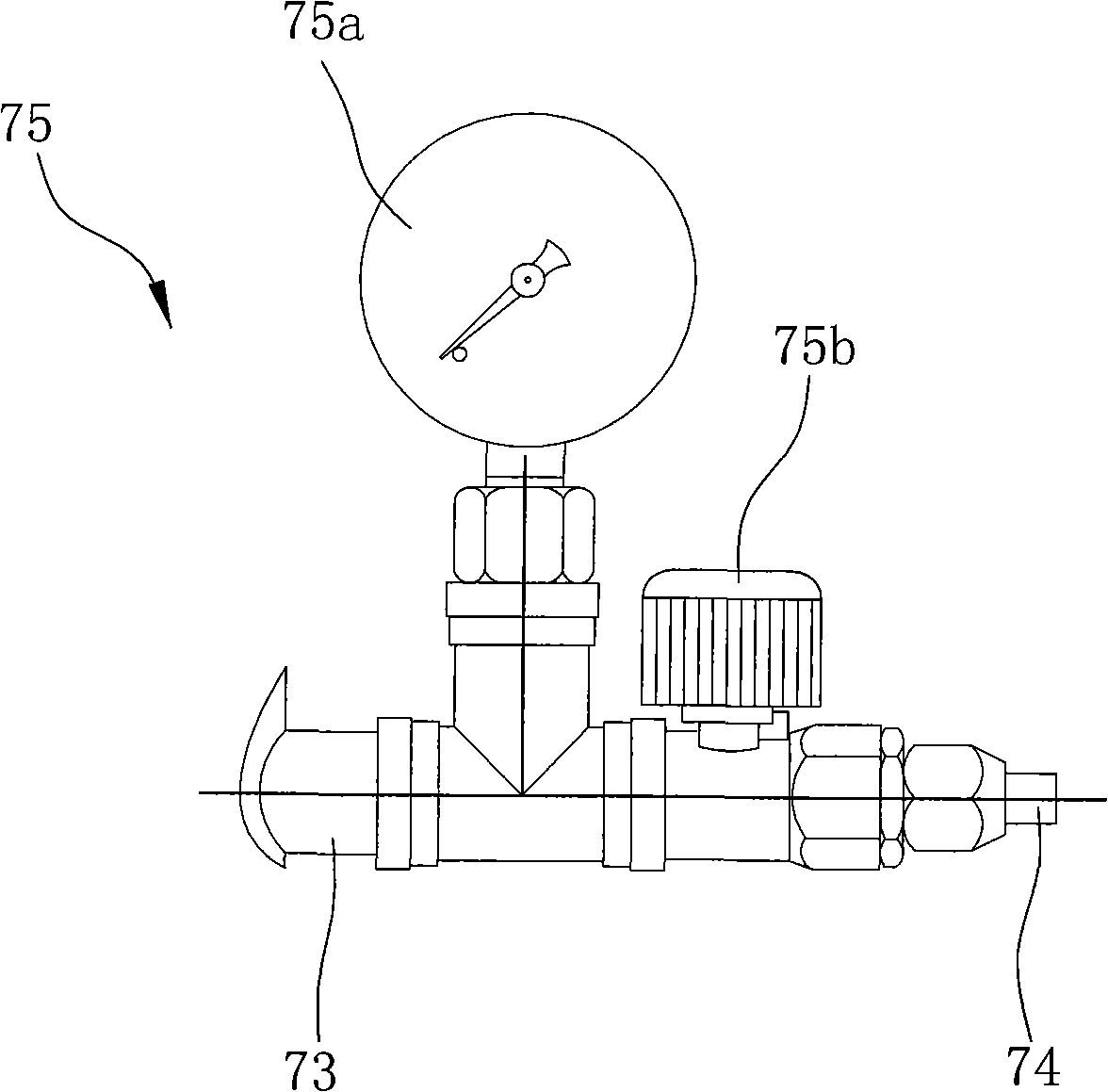

[0024] Wherein, the multiple aerators 71 in the biological filler 6 and the aeration device 7 are arranged in the pool body 1 in the form of unit modules 5, and each unit module 5 includes a module made of a plurality of hollow tubes 52 Support 51, the X-shaped supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com