Single-cell micromanipulation device for microinjection

A technology of microinjection and micromanipulation, which is applied in the field of microsystems, can solve the problems of inability to meet the application requirements of cell microinjection, the inability to accurately adjust the cell posture, and the long training period of operators, so as to improve the degree of automation and experimental efficiency, Improve the success rate of the experiment and the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

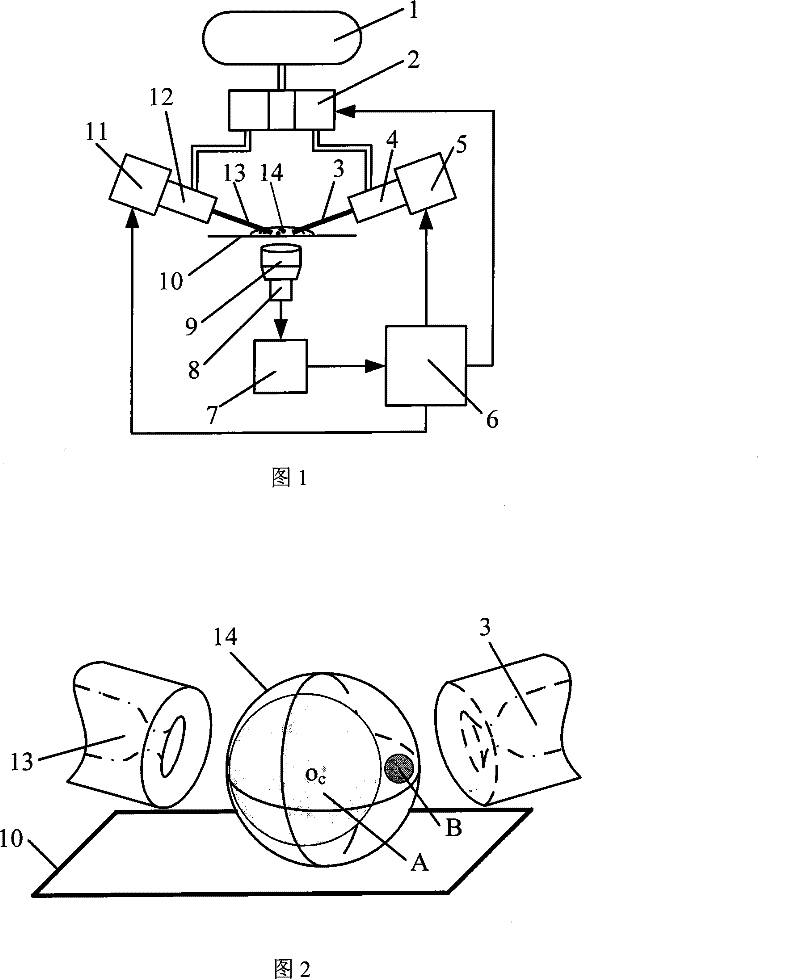

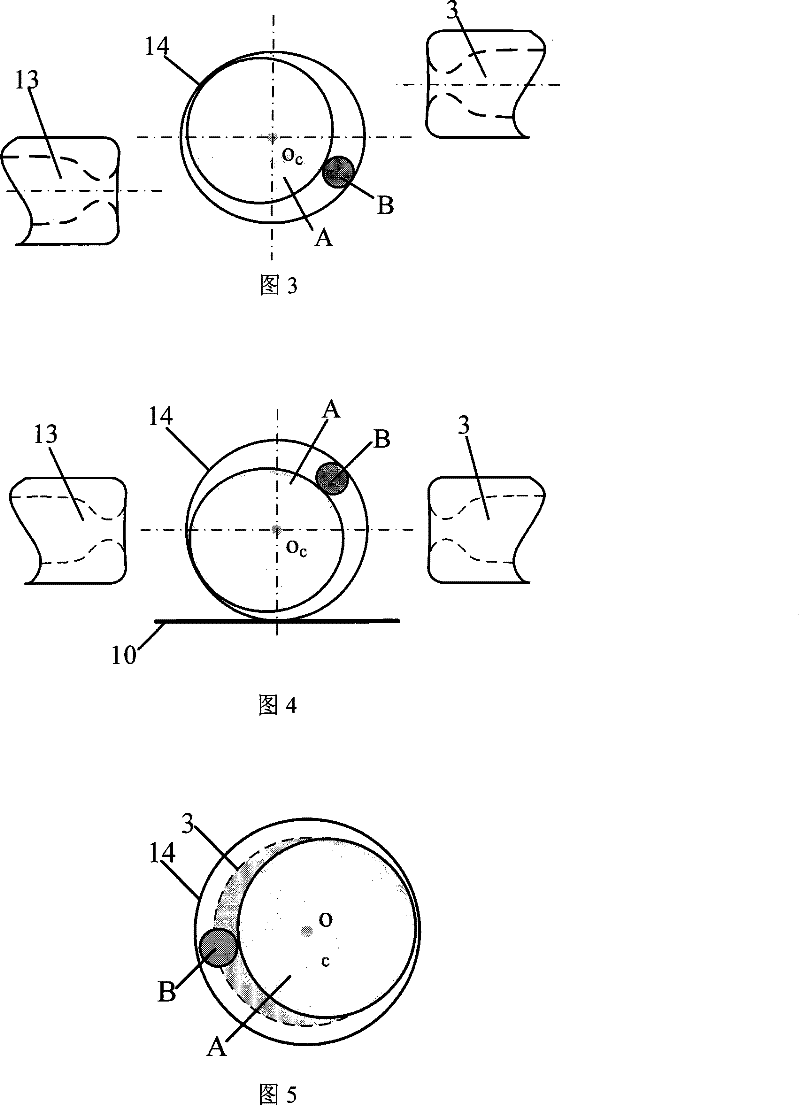

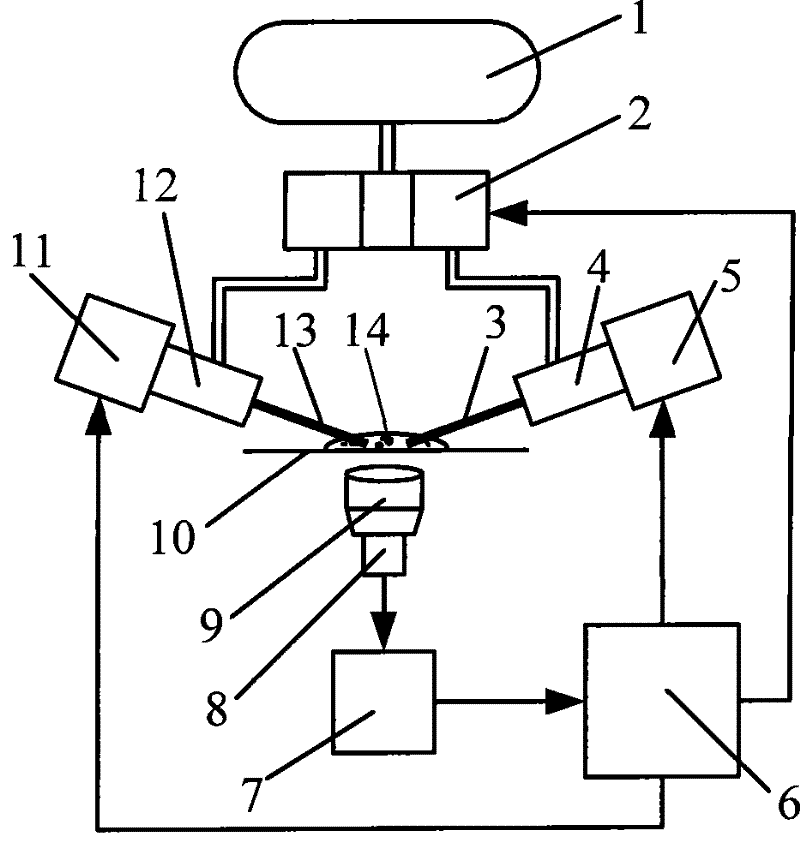

[0018] Such as image 3 , during the cell operation process, the left and right end effectors 13, 3 form a stable single-cell micro-operation flow field with controllable velocity distribution on the inverted microscope workbench 10 to adjust the posture of the operated cell. The left and right end effectors 13, 3 and the o of the operated cell 14 c It is distributed in the center of symmetry. Under the condition of equal pressure applied by the gas source 1 and the pressure control valve 2, the internal cell culture fluid flows out of the port at the same speed, and forms an o c Centered vortex flow field. Under the action of the viscous drag force of the culture medium, the manipulated cells 14 are subjected to a planar force couple, resulting in rotational movement in the horizontal plane. By setting parameters such as the pressure value and action time of the left and right end effectors 13, 3, the rotation angle of the operated cell 14 in the horizontal plane can be adj...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap