Method and device for removing loose material on wavy surfaces of stamped coal used for coking

一种松散、波形的技术,应用在装料装置、炼焦炉、石油工业等方向,能够解决不能加工煤饼等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

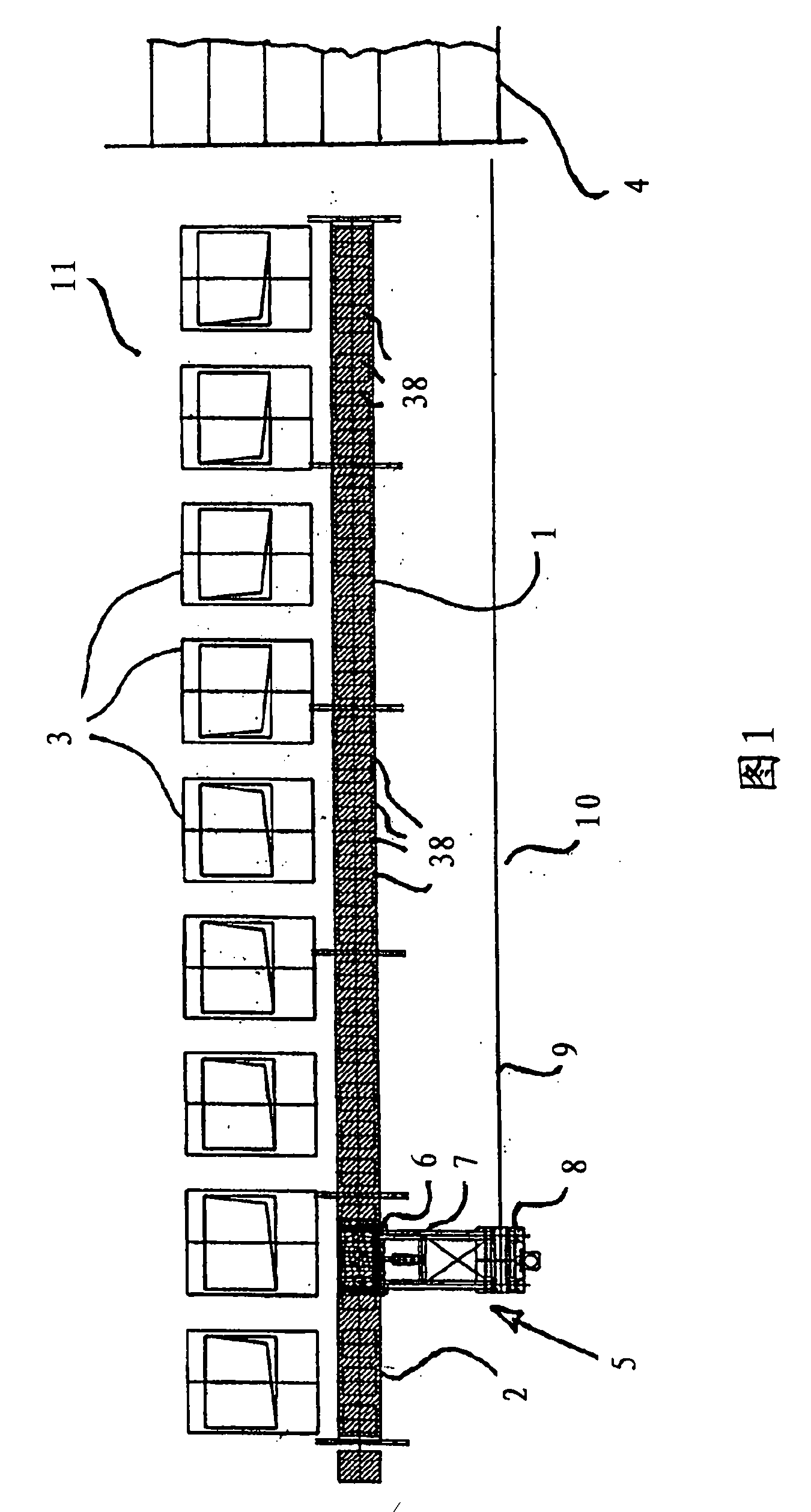

[0032] FIG. 1 shows a charging unit 11 for a coke oven with a briquette 1 produced in a compaction mold 2 and a filling device 3 as well as a furnace group 4 .

[0033] The device 5 according to the invention has a structural unit 6 and a connection device 7 (for connection) to a holding device 8 arranged movably on a rail 9 , which device is mounted on a loading unit 11 . The track 9 is only schematically shown in FIG. 1 .

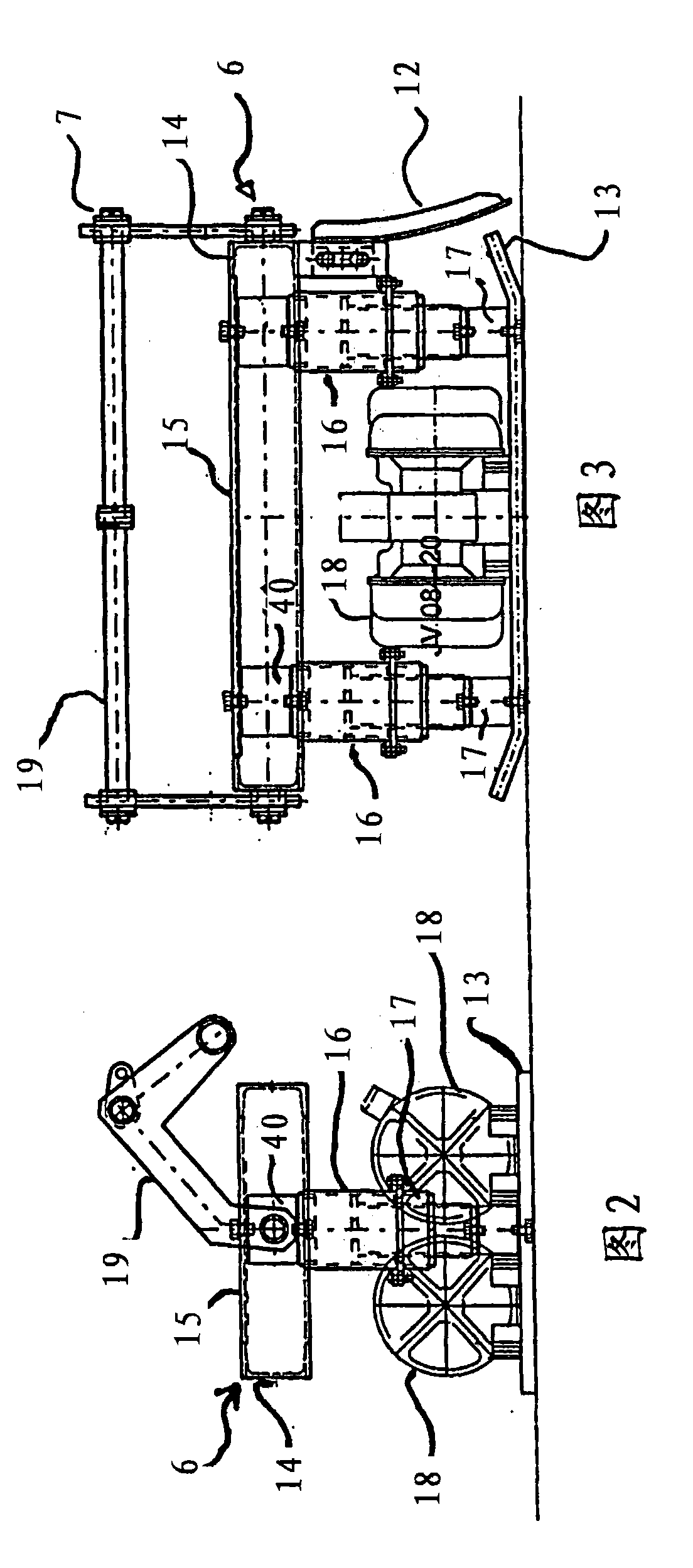

[0034] The structural unit 6 shown in detail in FIGS. 2 and 3 comprises a scraper 12 , an impact plate 13 and a device frame 14 for connecting these components.

[0035] The device frame 14 has a plate 15 , on which vertical telescopic guides 16 are mounted via two damping elements 40 , which in turn are connected to the impact plate 13 via damping elements 17 . The impact plate 13 is driven by two counter-running vibration (unbalance) motors 18 arranged on the impact plate.

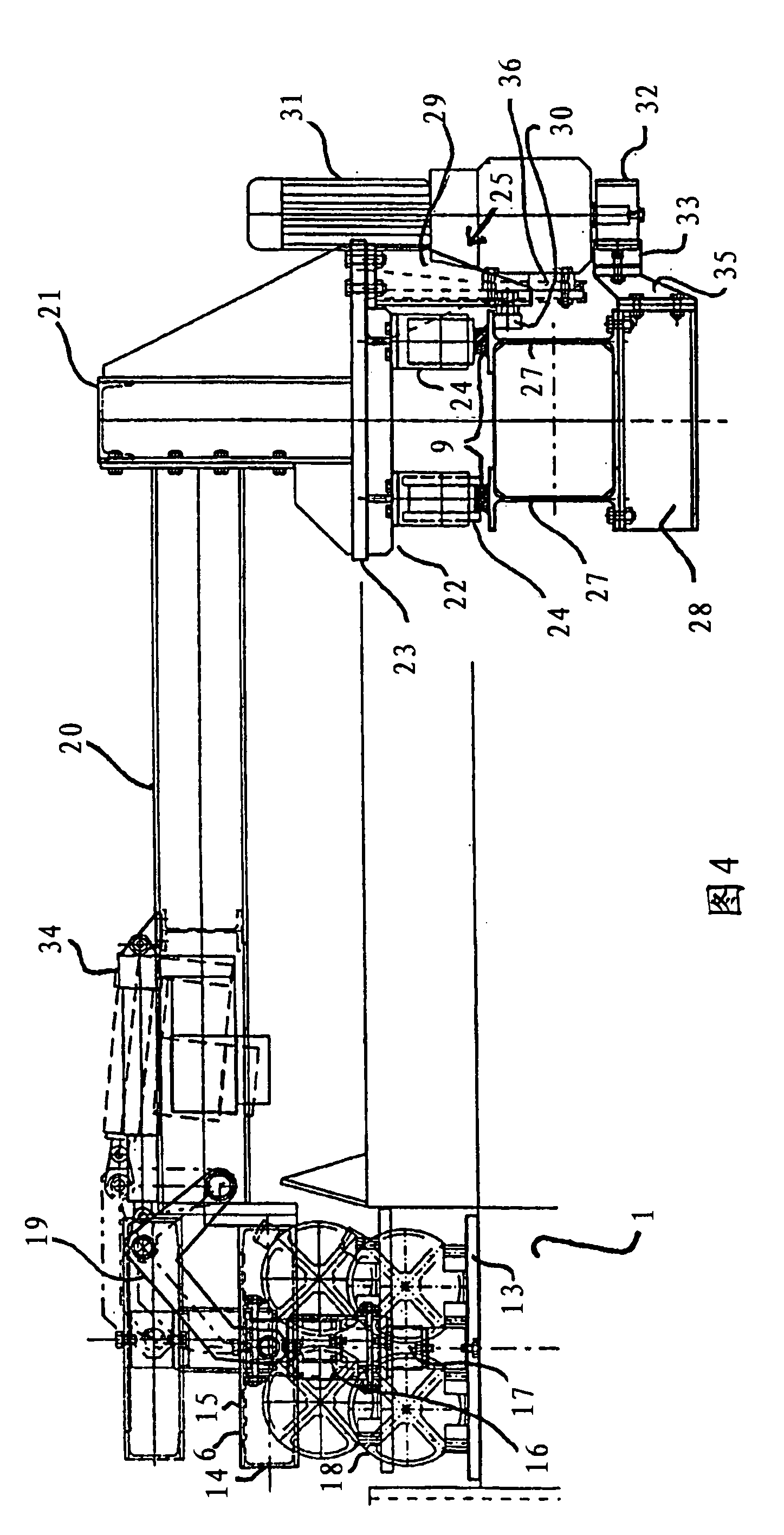

[0036] As shown in FIG. 4 , a height-adjustable lever linkage 19 is fastened ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com