Device for influencing an exhaust gas flow

A technology of exhaust flow and driving equipment, which is applied in the direction of mechanical equipment, electric control of exhaust treatment devices, exhaust treatment, etc., can solve the problems of reliable continuous operation and danger, and achieve the effect of light size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

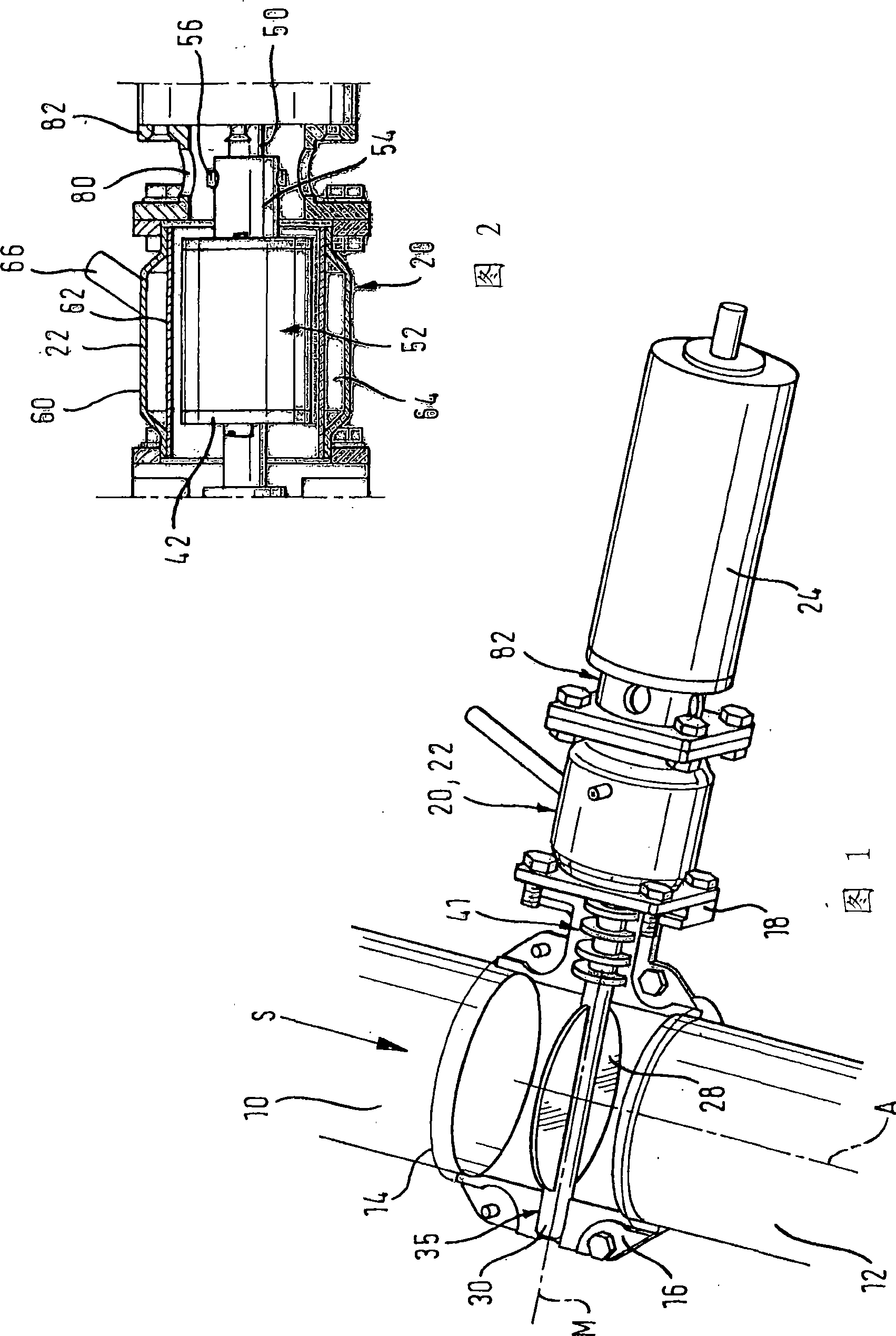

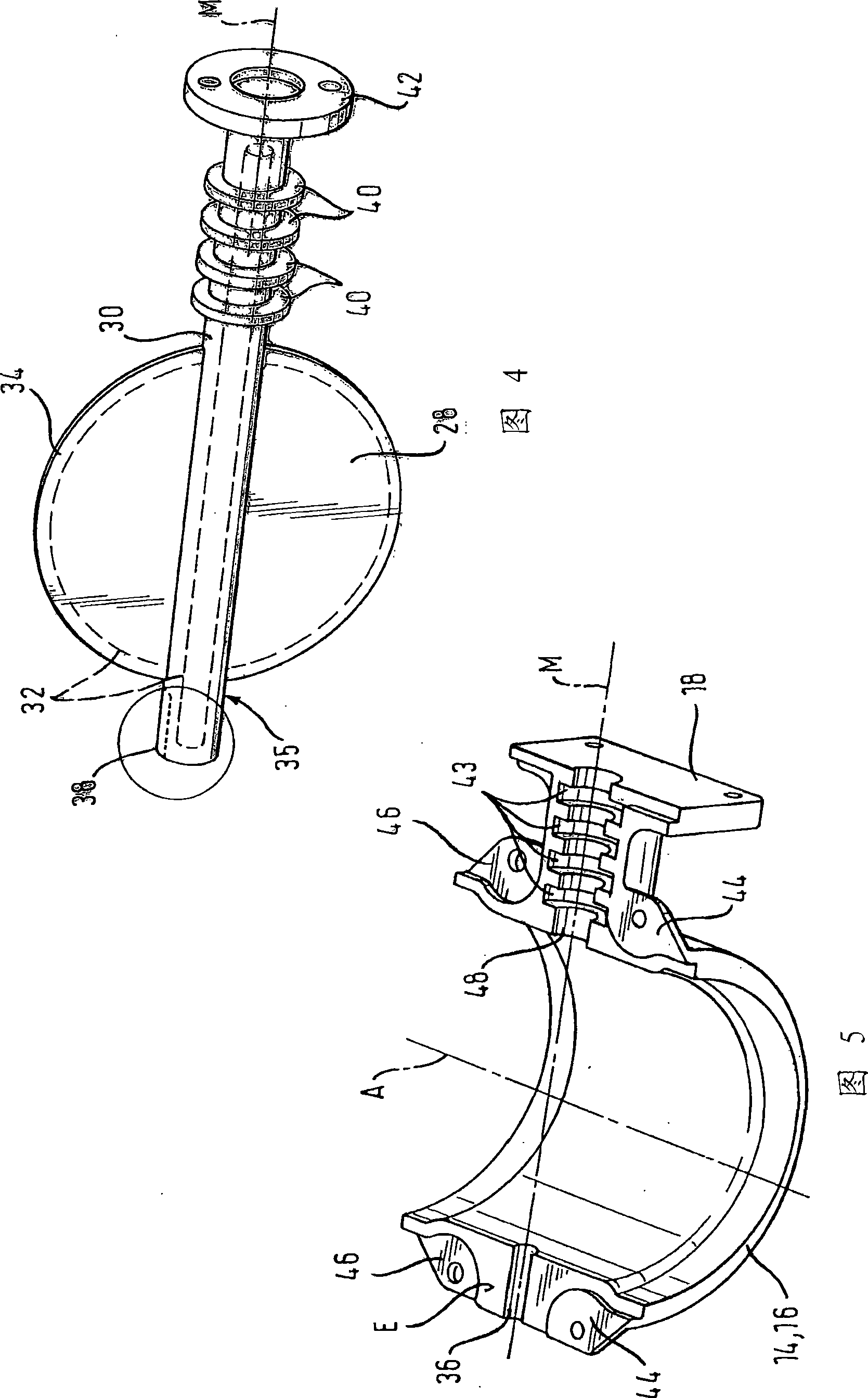

[0032] Figure 1 shows a device for disturbing the flow of exhaust gas, more precisely for controlling the acoustic emissions of the exhaust branch of a combustion engine. A tail gas supply pipe 10 supplies hot tail gas to the plant, while a duct 12 directs the hot tail gas from the plant towards the outlet. A linear section on one side of the device rests between the pipes 10, 12, which is concentric with said pipes and consists of two half-shells 14, 16 which are geometrically, formally And the size is the same.

[0033] FIG. 5 shows one of the half shells 14 , 16 . The fastening flange 18 is formed integrally with the half-shells 14, 16, which are made of ceramic material or metal, preferably cast, and consists of two sections, each Associated with one of the half shells 14,16.

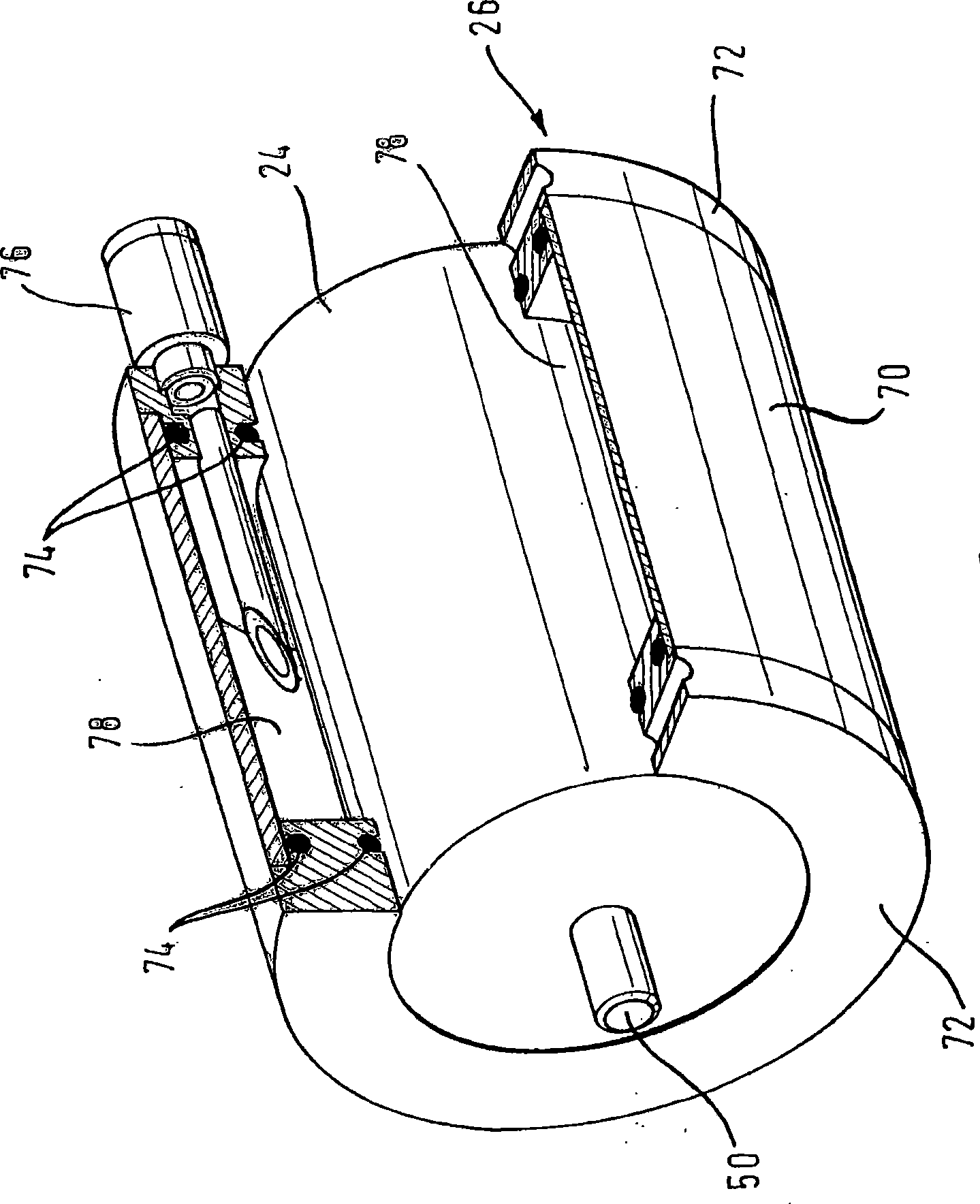

[0034] A unit consisting of a coupling 20 and an active cooling system 22 surrounding the coupling 20 (see FIG. 2 ) is flanged to the fastening flange 18 and has an electronic drive motor 24 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com