Method and device for constructing solid waste landfill yard with group silos

A landfill and population technology, applied in the direction of solid waste removal, etc., can solve the problems of complex composition, difficult treatment process, and high pollution concentration of leachate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

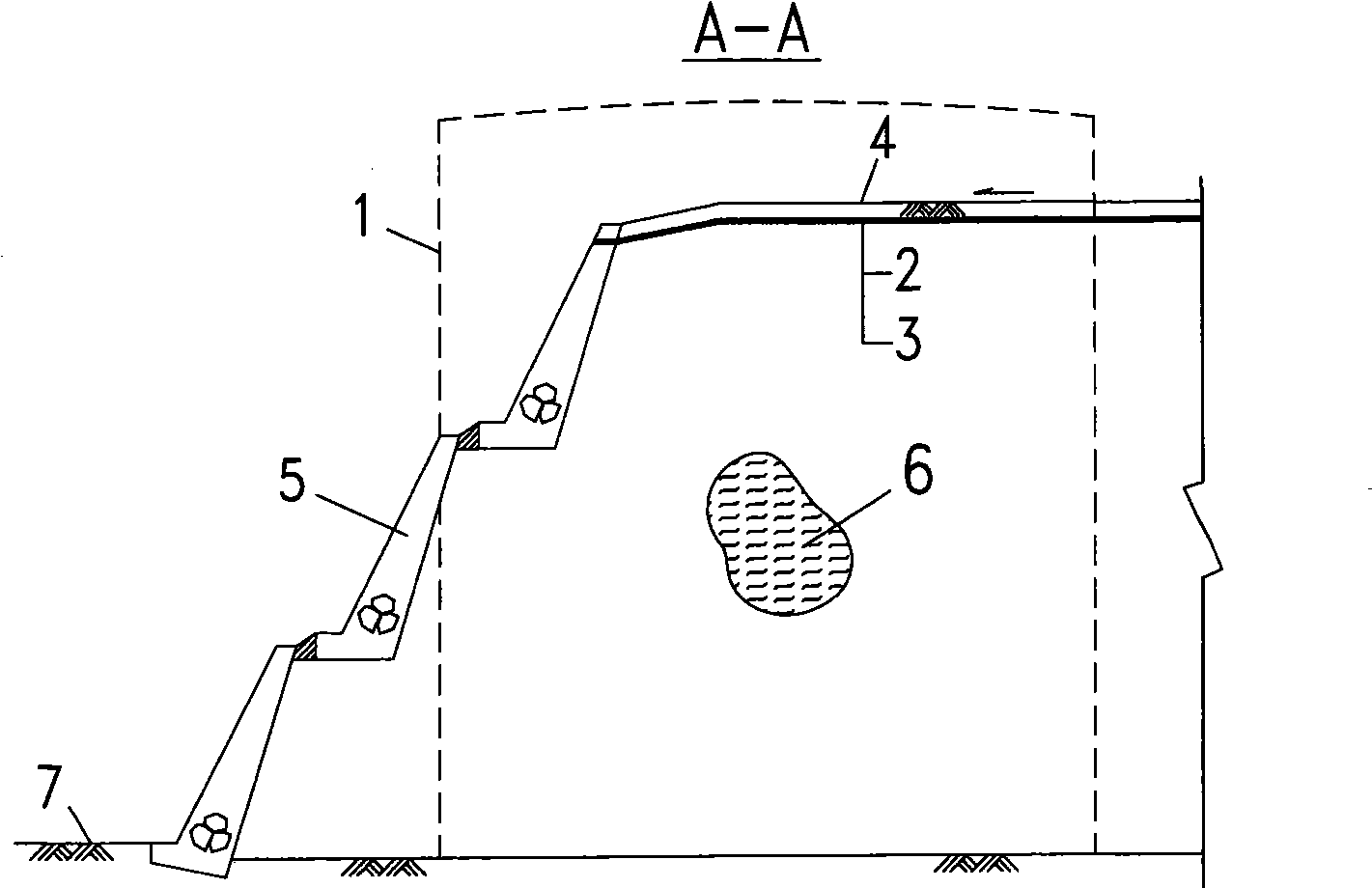

[0048] The following two examples of building solid waste landfills on plains are used to describe the specific implementation methods of solid waste as garbage or solid waste as tailings.

[0049] One, embodiment 1 (solid waste is rubbish 6):

[0050] 1. Design information:

[0051] The diameter of the designed silo is 20 meters, and the average height after filling is 22 meters, so the volume of a single silo is 6911 cubic meters. Based on 460 cubic meters of garbage per day, it takes 15 days (half a month) to fill one silo, and 24 silos can be filled in one year. If the design life of the landfill is 20 years, then a total of 24×20=480 silos need to be built, and the total amount of landfill is: 6911×480=3317280 cubic meters (ie 3.317 million cubic meters).

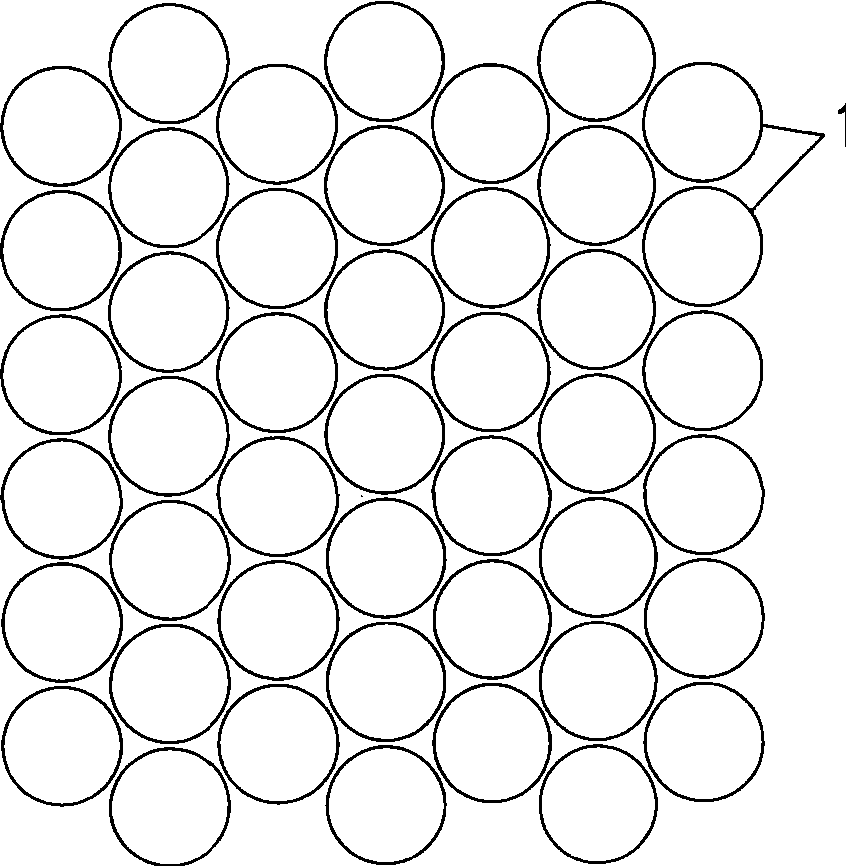

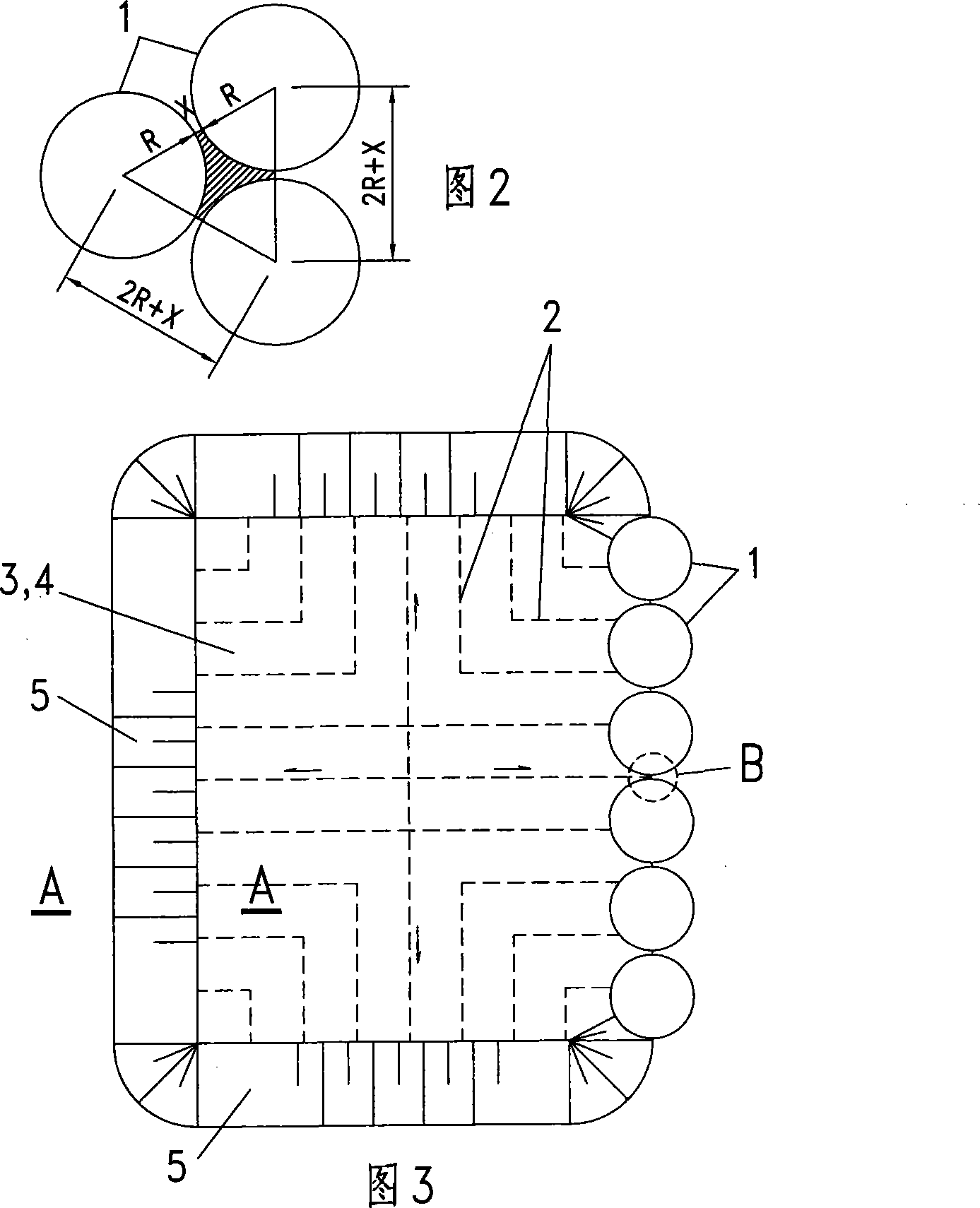

[0052] If 24 silos are arranged in every row, a total of 20 rows are arranged, and the center line of each adjacent silo is distributed in an equilateral triangle at 21 meters, as shown in Figure 2, R=10 meters; X=1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com