Dewatered sludge landfill method

A technology for dewatering sludge and sludge, applied in dehydration/drying/concentrated sludge treatment, water/sludge/sewage treatment, sludge treatment, etc., can solve problems such as insufficient strength, impact on the environment, coverage, etc., and achieve increased Overall stability, the effect of preventing environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

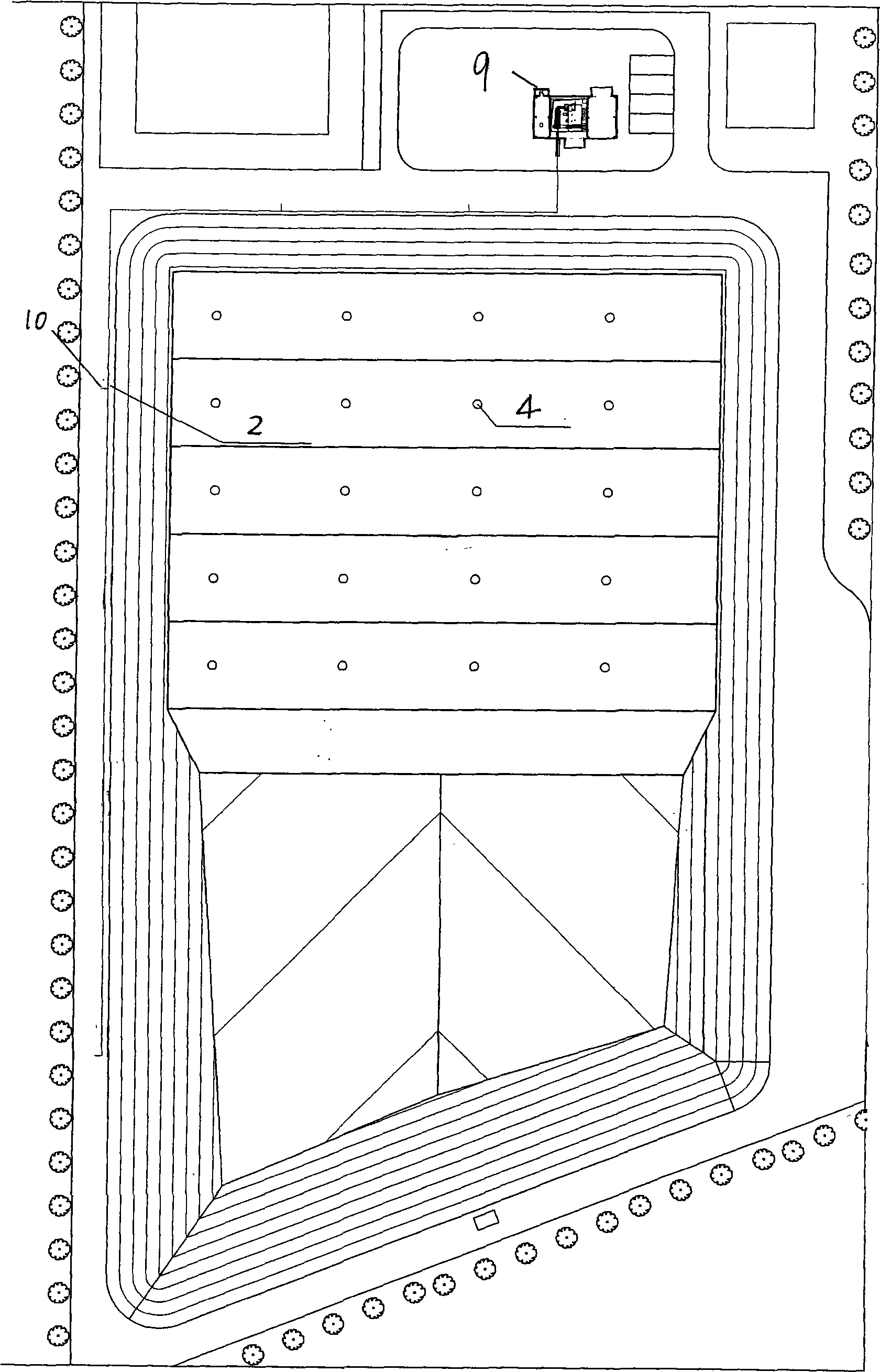

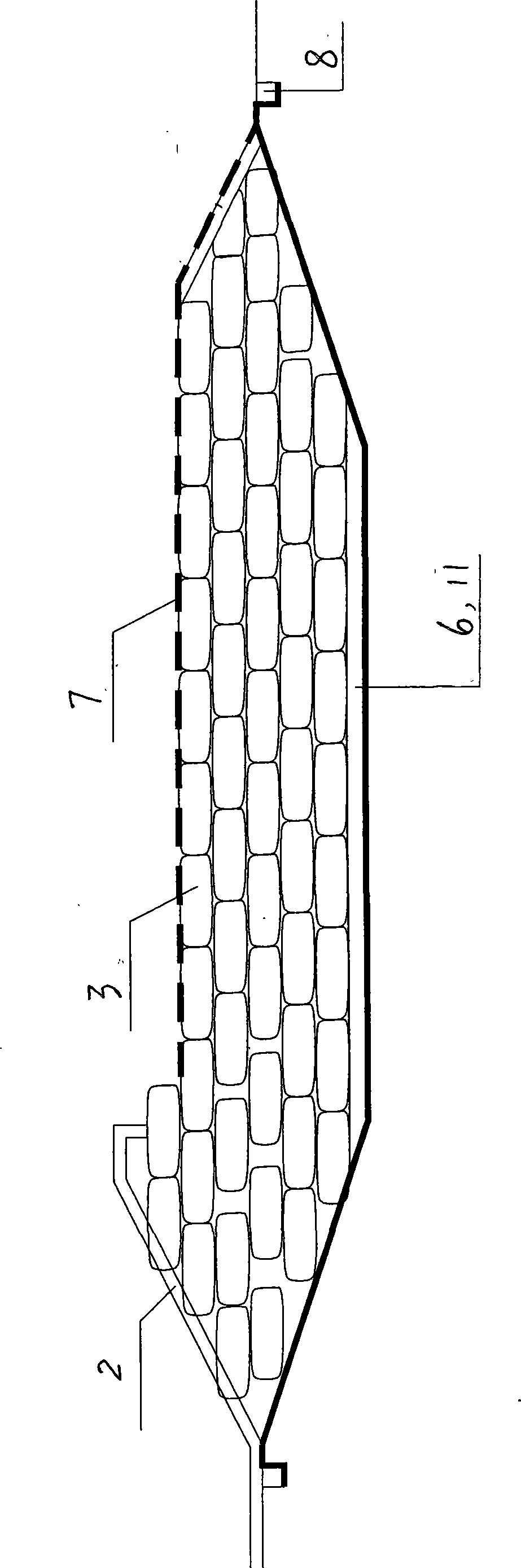

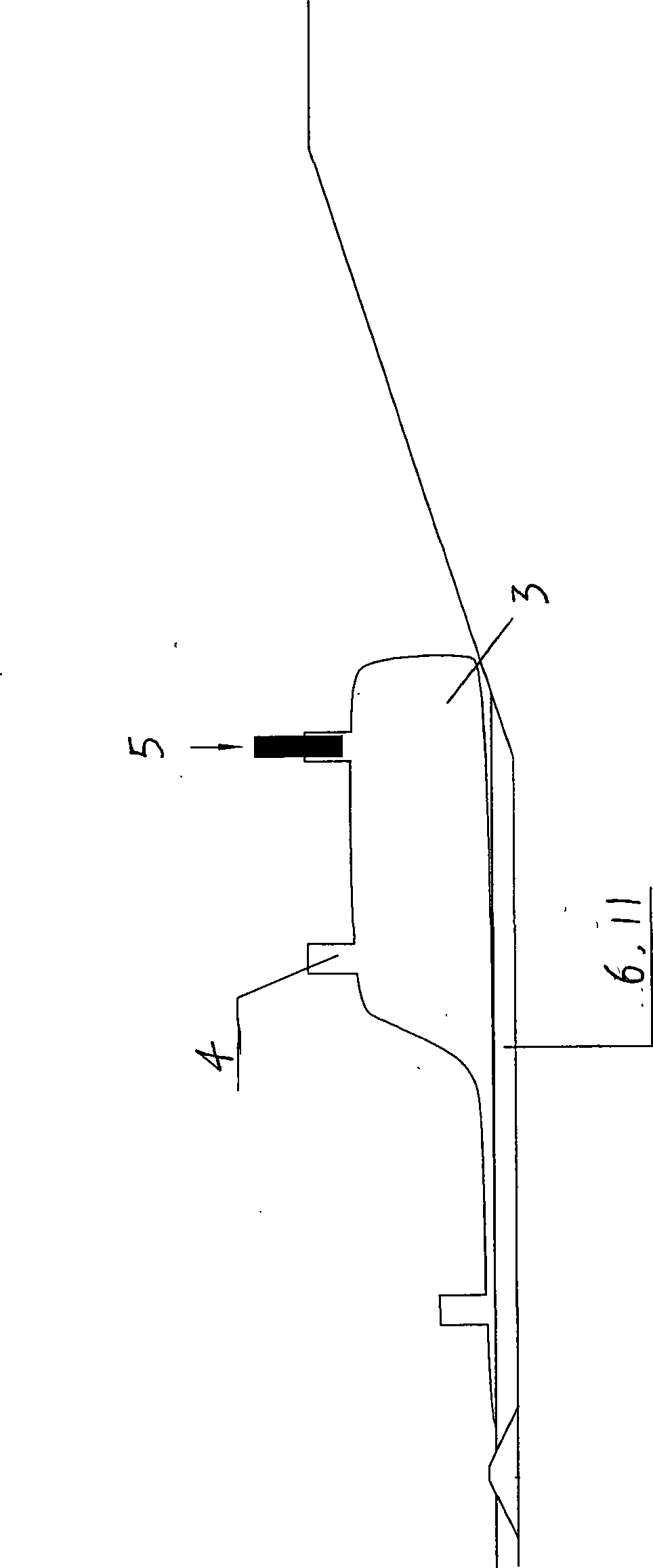

[0014] A method for landfilling dewatered sludge, comprising the following steps: A, discharging the incoming sludge into a silo 1, the bottom of the silo 1 is provided with an opening to connect with the sludge conveying pipeline 2; B, placing the geotextile bag 3 in the In the landfill, the geotextile bag 3 is provided with a plurality of feed openings 4 on one side, generally 1.5m-10m wide and 10m-60m long. Geotextile bags are made of woven geotextiles, or long and short fiber needle-punched non-woven geotextiles. C. Connect the sludge conveying pipe to the feed port of the geotextile bag; D. Load the sludge in the silo into the geotextile bag 3 through the sludge conveying pipe under the action of the external force 5 . Geotextile bags are generally 1.5m to 10m wide and 10m to 60m long. The sludge has been dehydrated to a moisture content of 60-90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com