Food flexible packing material with antibacterial function and use thereof

A flexible packaging and flexible packaging film technology, applied in the field of food packaging materials, can solve the problems of short antibacterial preservation time, restricted development and high price, and achieve the effects of extending the preservation period, prolonging the shelf life, and being widely used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] The polyethylene (PE) resin accounts for 96.35%, the nano zinc oxide accounts for 3.65%, and the surface modifying agent accounts for 0.1% (percentage by weight) in the antibacterial functional food soft packaging material of the present invention. The antibacterial properties of the food flexible packaging materials and the packaging films made of the above weight percentages are shown in Tables 1-1, 1-2, and 1-3.

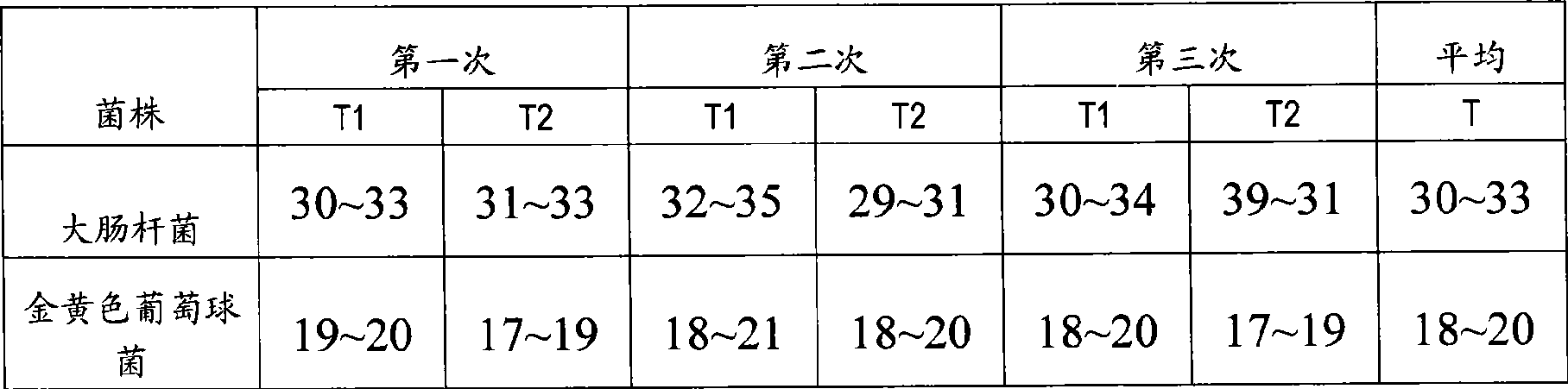

[0009] Table 1-1 Bacteriostatic properties of inorganic composite antibacterial agents

[0010]

[0011] Note: T represents the diameter of the antibacterial ring, T1 represents the first pattern, and T2 represents the second pattern.

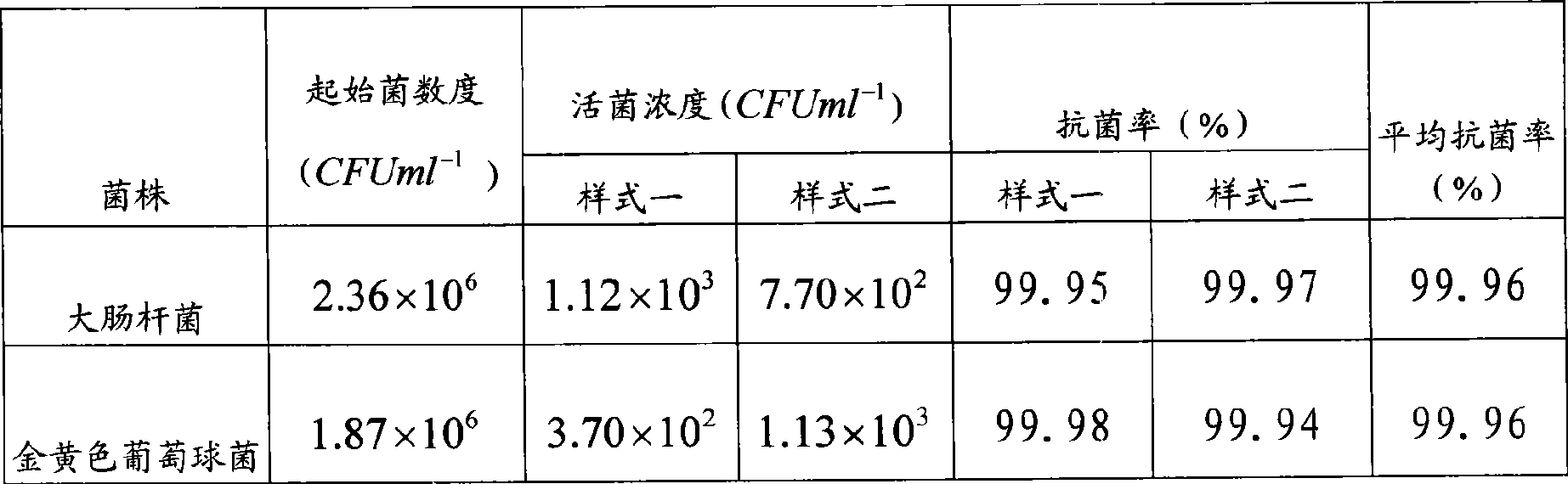

[0012] Table 1-2 Antibacterial properties of inorganic composite antibacterial agents

[0013]

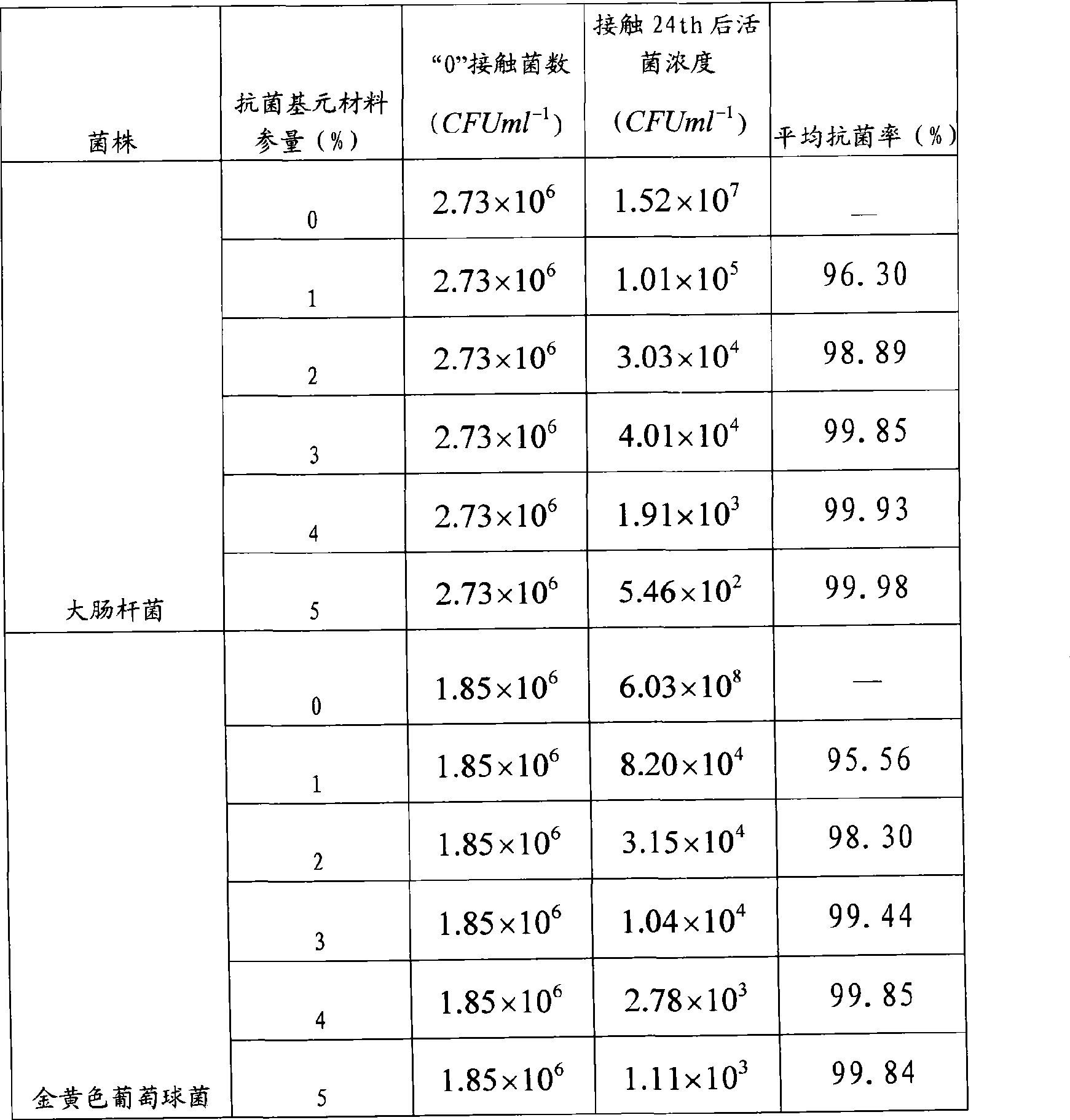

[0014] Table 1-3 Antibacterial properties of food flexible packaging films

[0015]

Embodiment 2

[0017] The polyethylene (PE) resin accounts for 98.80% (weight), the nanometer zinc oxide accounts for 1.1% (weight) and the surface modifying agent accounts for 0.1% (weight) in the antibacterial functional food soft packaging material of the present invention. Table 2-1, 2-2 and 2-3 show the antibacterial properties of the food flexible packaging materials and the packaging films made of the above weight percentages.

[0018] Table 2-1 Bacteriostatic properties of inorganic composite antibacterial agents

[0019]

[0020] Note: T represents the diameter of the antibacterial ring, T1 represents the first pattern, and T2 represents the second pattern.

[0021] Table 2-2 Antibacterial properties of inorganic composite antibacterial agents

[0022]

[0023] Table 2-3 Antibacterial properties of food flexible packaging films

[0024]

[0025]

Embodiment 3

[0027] The polyethylene (PE) resin accounts for 94.92% (weight), the nano zinc oxide accounts for 4.98% (weight) and the surface modifier accounts for 0.1% (weight) in the antibacterial functional food flexible packaging material. The antibacterial properties of the food flexible packaging materials and the packaging films made of the above weight percentages are shown in Tables 3-1, 3-2, and 3-3.

[0028] Table 3-1 Bacteriostatic properties of inorganic composite antibacterial agents

[0029]

[0030] Note: T represents the diameter of the antibacterial ring, T1 represents the first pattern, and T2 represents the second pattern.

[0031] Table 3-2 Antibacterial properties of inorganic composite antibacterial agents

[0032]

[0033] Table 3-3 Antibacterial properties of food flexible packaging films

[0034]

[0035] As can be seen from Examples one, two, and three, when polyethylene (PE) resin accounts for 96.35% (weight), nano-zinc oxide accounts for 3.65% (weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com