Power apparatus with temperature difference as energy

A power device and energy technology, which is applied in the field of temperature difference energy power devices, can solve the problems of pressure loss, high fluid channel accuracy and increased processing difficulty, and achieves the effects of reducing machining accuracy, reducing incoherence, and improving sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

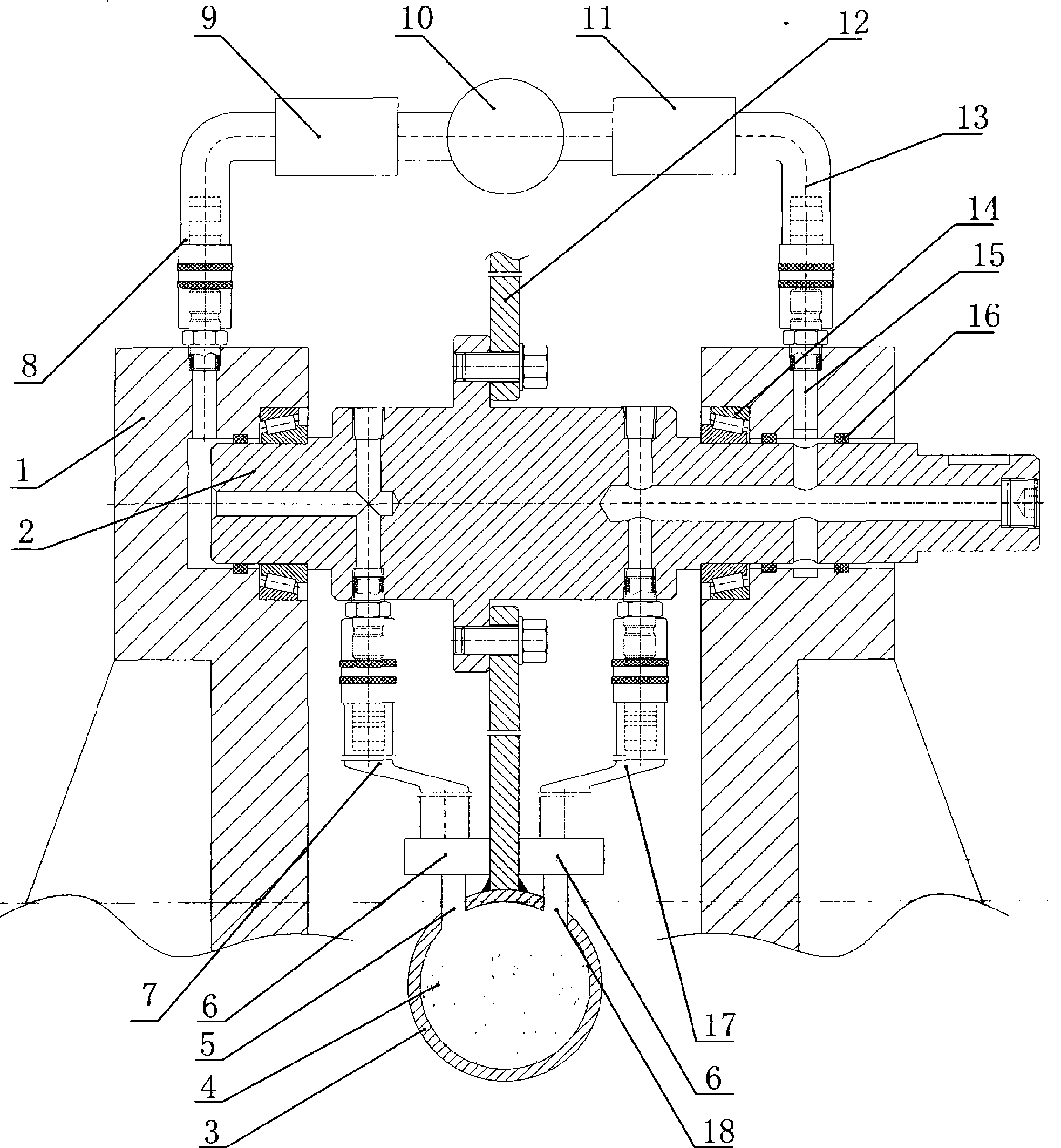

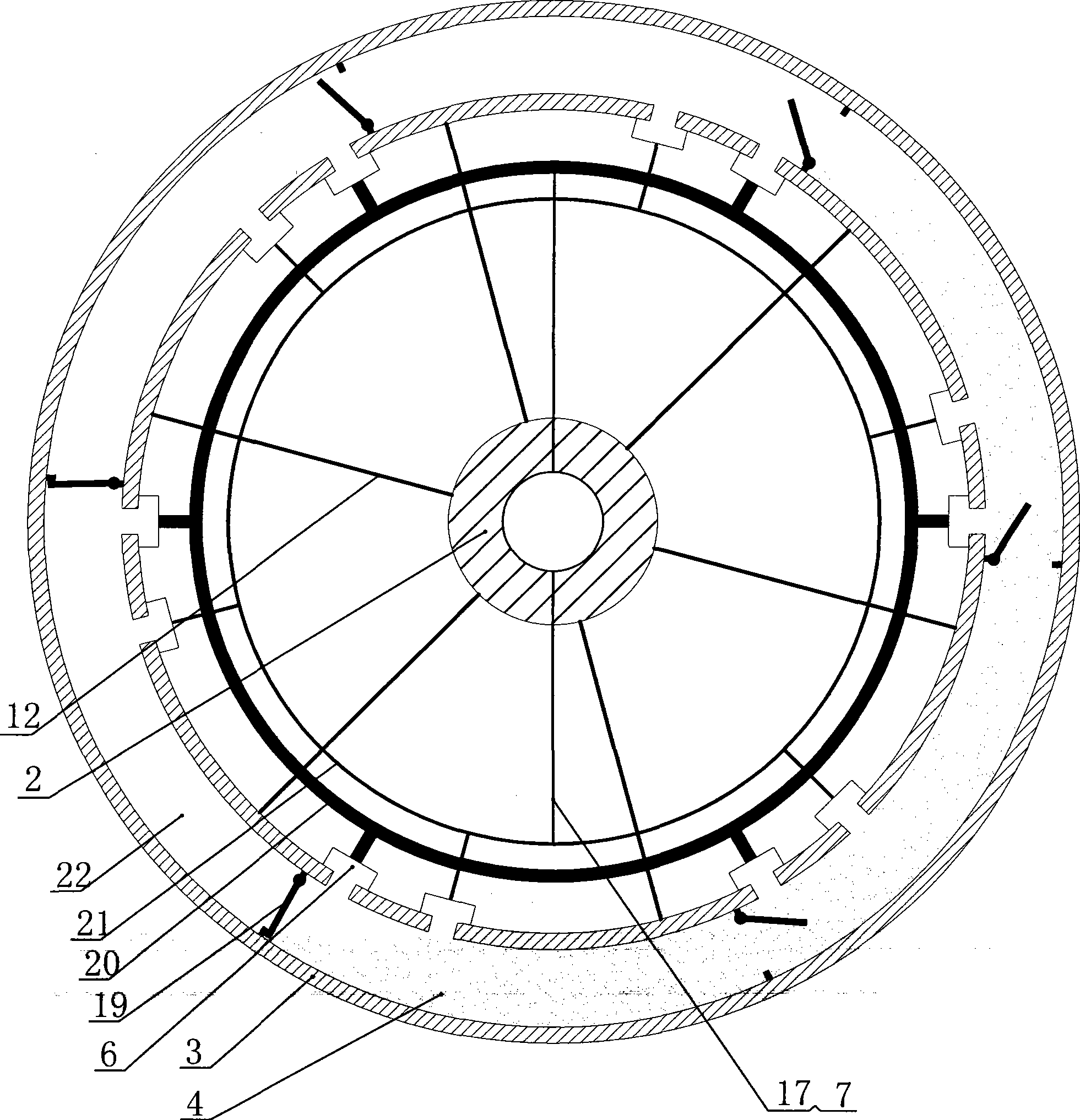

[0022] Embodiment: a kind of temperature difference energy source power plant (see attached figure 1 attached figure 2 ), the two ends of the rotating shaft 2 are arranged on the support 1 through bearings 14, the two ends of the rotating shaft are provided with airflow ducts, one end of the rotating shaft is completely covered by the support, the other end of the rotating shaft extends out of the support, and a process plug is set at the end, the support There are small pipes 15 on the top, one small pipe is connected to the steam generator 9 through the intake pipe 8, and the other small pipe is connected to the condenser 11 through the exhaust pipe 13, and a pump 10 is arranged between the steam generator and the condenser. The pipelines are also connected to the airflow pipelines at both ends of the rotating shaft respectively, and the sealing ring 16 is used to seal between the rotating shaft and the support. The rotating shaft is provided with a fluid channel 3 with a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com