Extraction method for dimension shape characteristics of profiled fiber

A technology of special-shaped fibers and extraction methods, applied in image data processing, material inspection products, instruments, etc., can solve the problems of poor accuracy, time-consuming and labor-intensive methods, and achieve the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

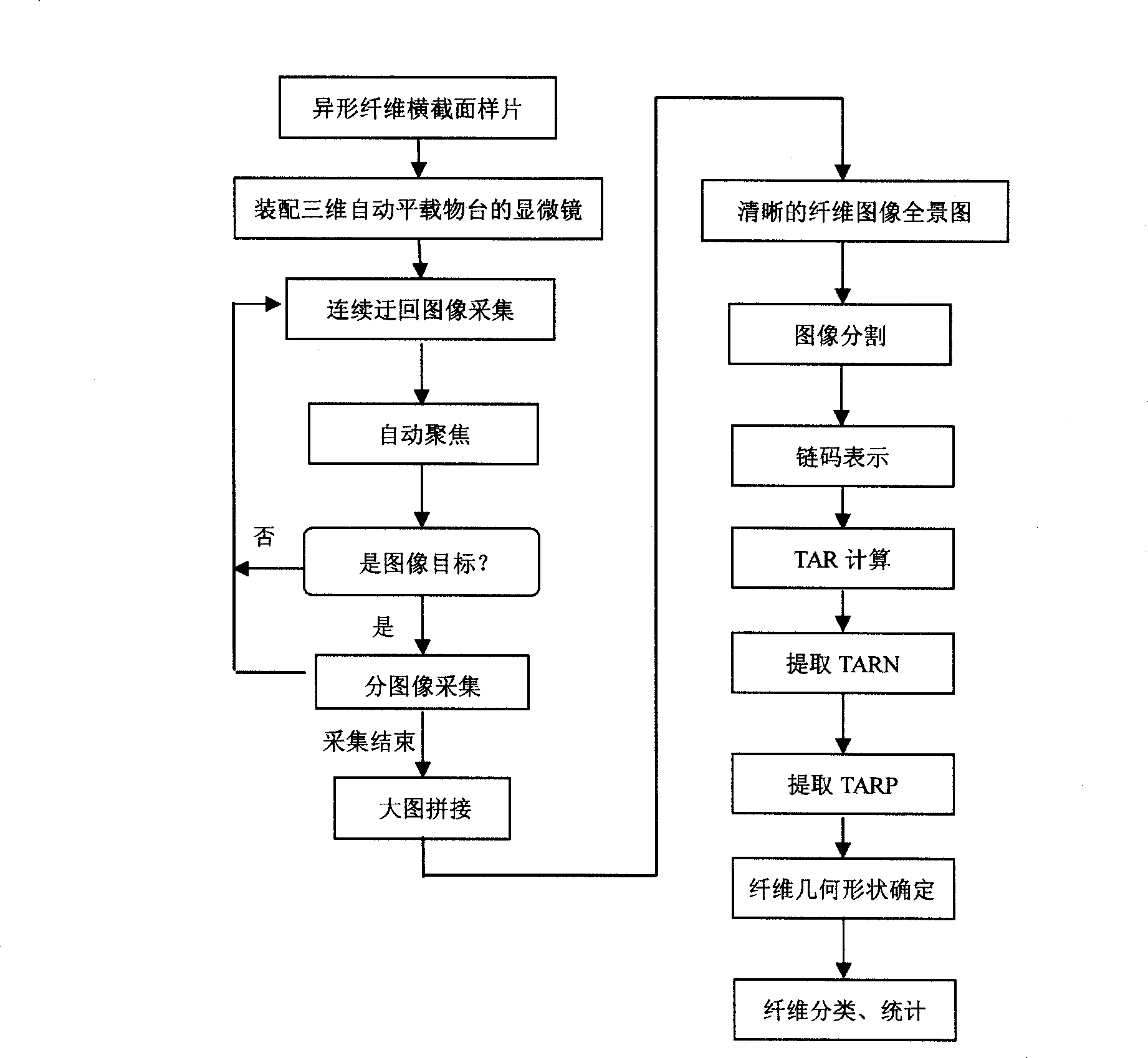

[0016] refer to figure 1 , which is a flow chart of the steps of the special-shaped fiber extraction method of the present invention.

[0017] As shown in the figure, the stepper motor in the XYZ directions of the three-dimensional automatic stage is controlled by the control software of the image extraction device through the serial port, so as to realize the movement control of the stage in the horizontal and vertical directions, so that the optical microscope can work in the most The images are collected and classified according to the best focus state.

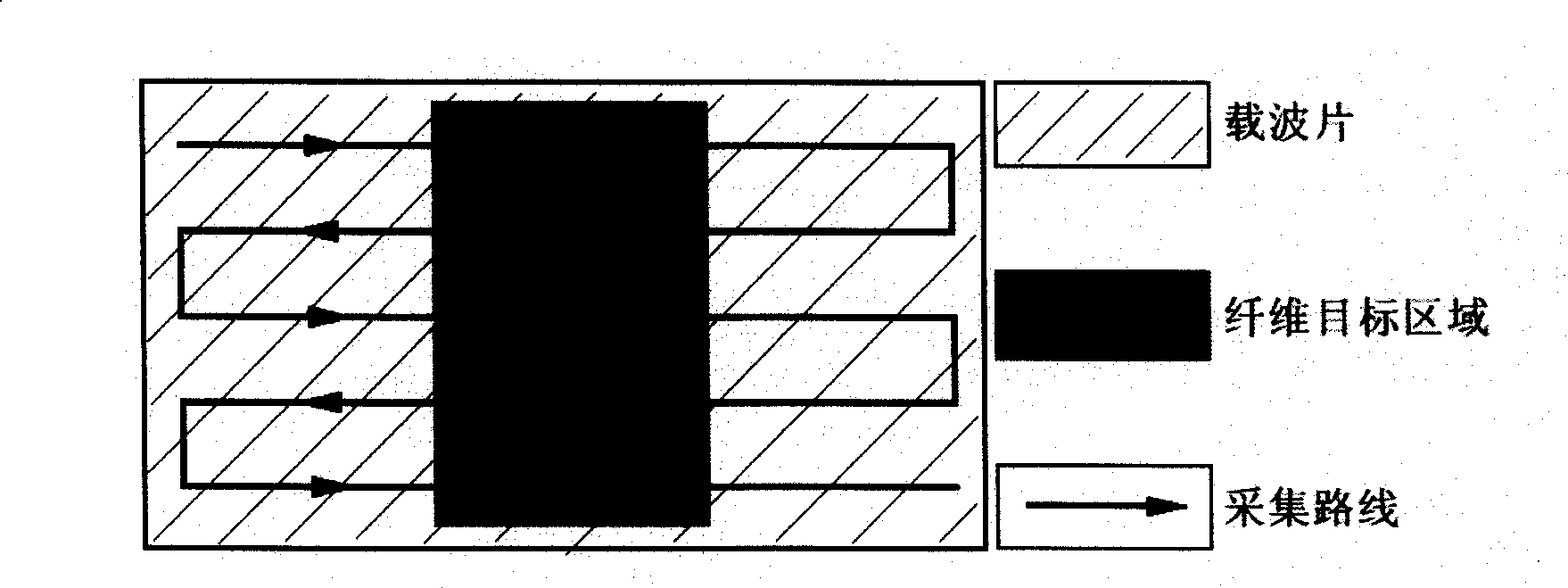

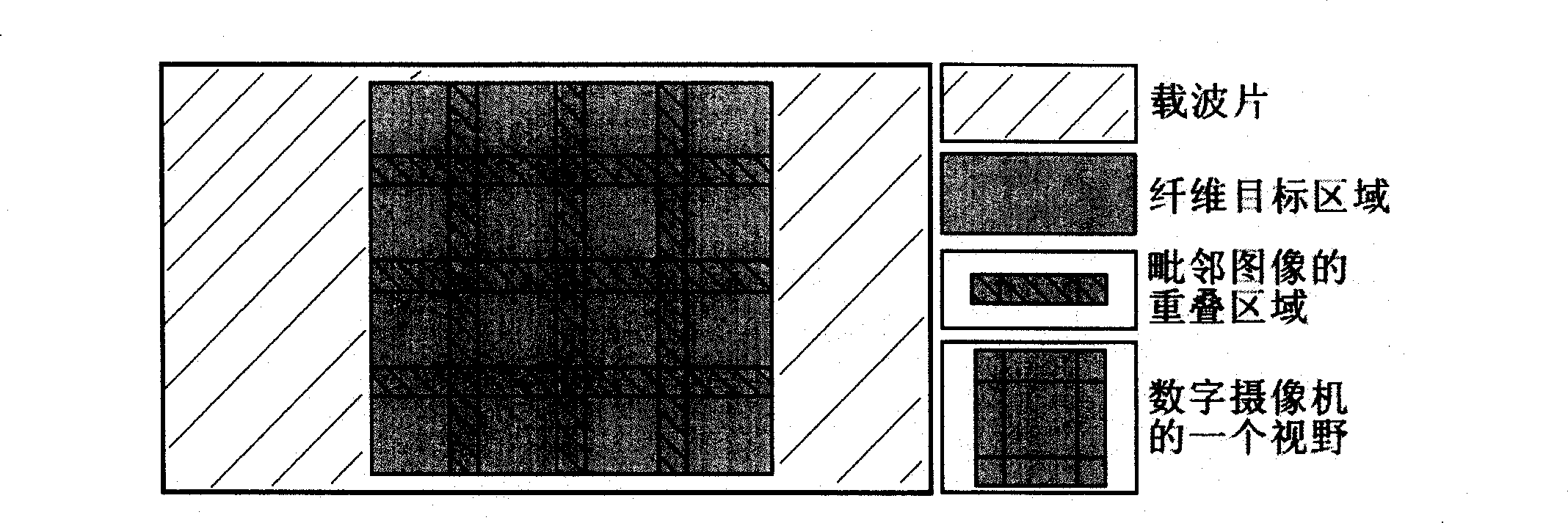

[0018] First of all, it is necessary to automatically classify the shaped fibers, including image segmentation, chain code representation, triangle area (TAR) calculation, triangle negative area (TARN) representation, triangle positive area (TARP) representation, and shaped fiber classification. Then, image acquisition is performed. Image acquisition is to collect the image content of the target area of the shaped fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com