High-speed test device

A testing device and high-speed technology, applied in the direction of measuring device, electronic circuit testing, measuring electricity, etc., can solve the problems of cost and man-hours, affecting the transmission characteristics of high-frequency signals, deformation of the probe card 12, etc., to reduce the production process, The effect of shortening the production period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

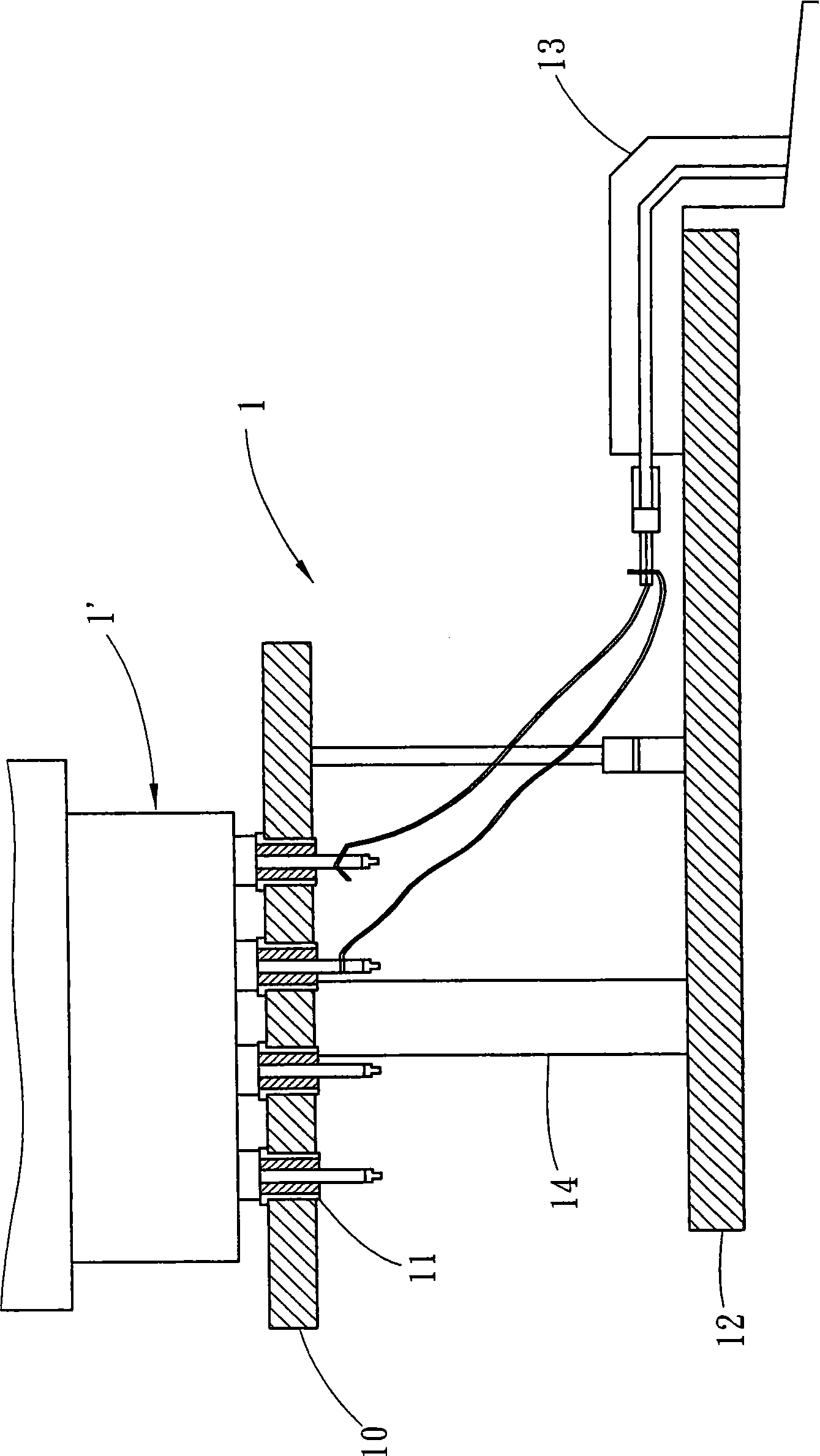

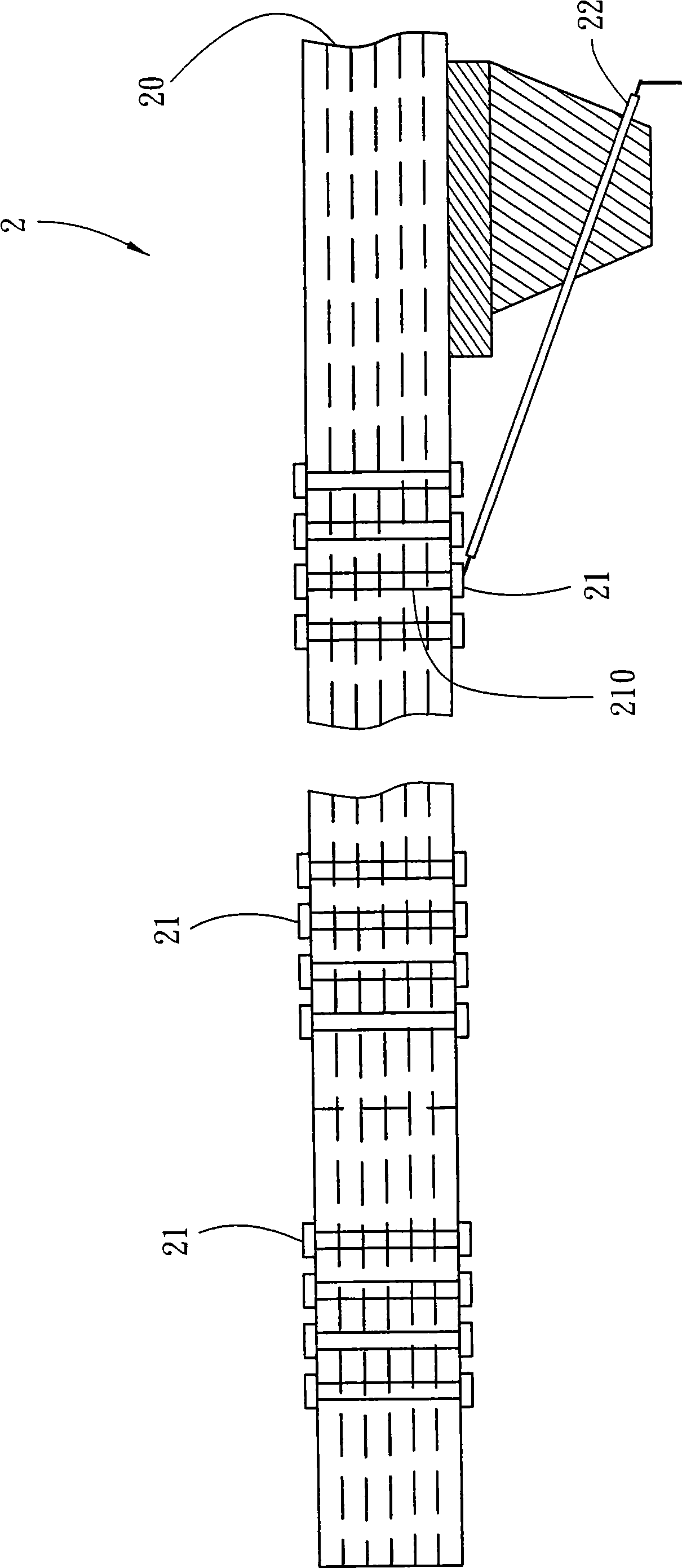

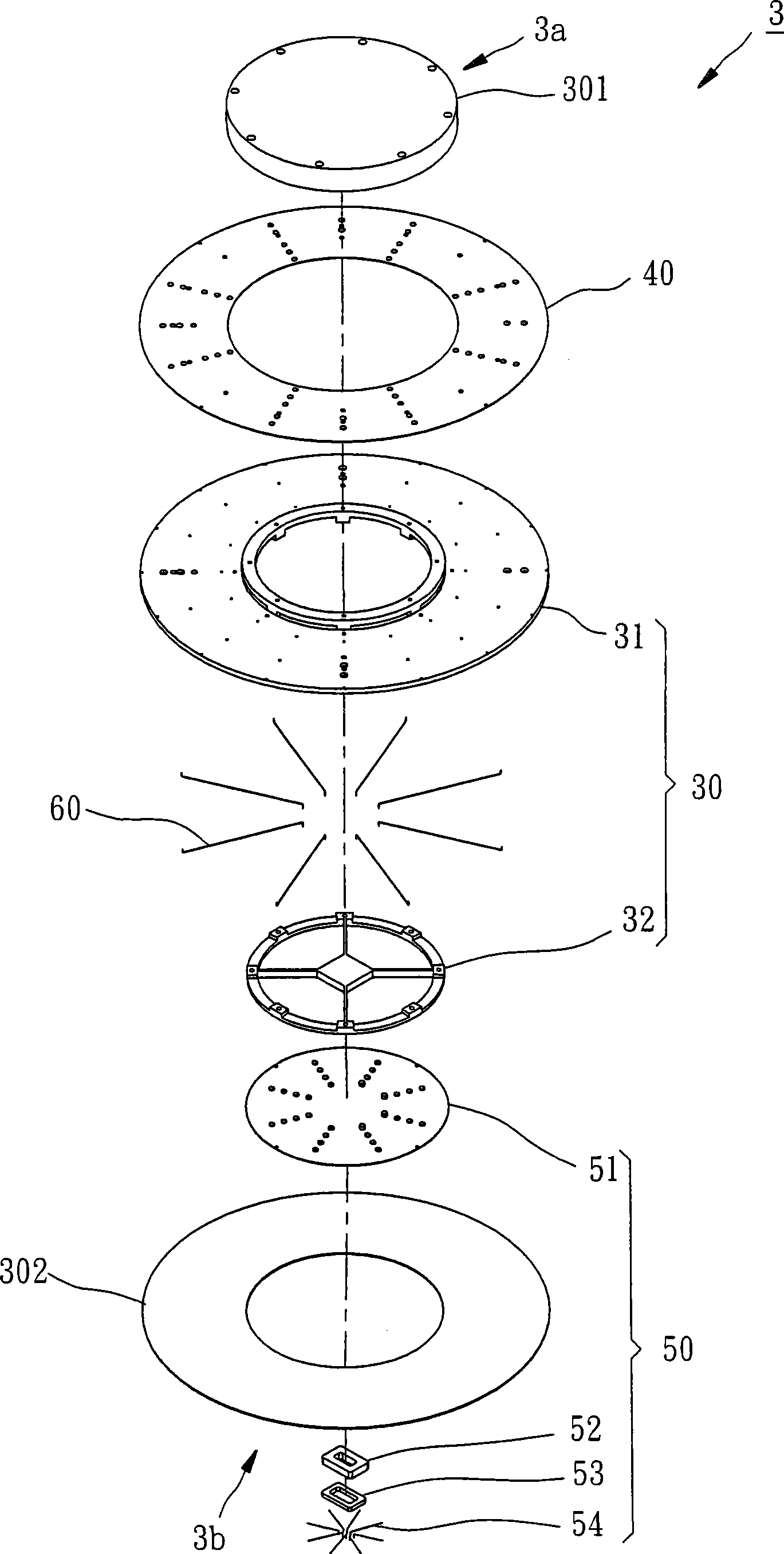

[0049] Hereinafter, some preferred embodiments are listed in conjunction with the diagrams, in order to describe the structure and effect of the present invention in detail, wherein the brief description of the diagrams used is as follows:

[0050] image 3 It is an exploded perspective view of the first preferred embodiment provided by the present invention;

[0051] Figure 4 It is a perspective view of the bottom of the first preferred embodiment above;

[0052] Figure 5 It is a structural schematic diagram of the above-mentioned first preferred embodiment;

[0053] Figure 6 It is a schematic bottom perspective view of the support frame provided by the first preferred embodiment above;

[0054] Figure 7 It is a combined top view of a part of the structure provided by the above-mentioned first preferred embodiment, and it is a schematic diagram of a combined structure with circuit layers, signal lines and probe sets arranged on the support frame;

[0055] Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com