Graphite composite heat conducting sheet

A heat-conducting sheet and graphite sheet technology, used in cooling/ventilation/heating transformation, discharge lamps, discharge tubes, etc., can solve the problems of poor uniformity of heat dissipation, and achieve convenient coating, high thermal conductivity, and satisfactory fit The effect of strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Thermal conductivity and temperature distribution uniformity are important factors affecting image quality and lifetime of large flat panel displays. If the heat-conducting material can quickly transfer the heat from all parts of the large flat-panel display along the screen, the temperature of the screen can be maintained evenly. At this time, the brightness of each area of the screen is only determined by the control of electrical signals, and the display effect of the screen can reach Ideal state.

[0039] Graphite material has a high in-plane thermal conductivity, which is 30-100 times that of thermally conductive silicone rubber, which can keep the temperature in each area of the large flat panel display uniform and eliminate thermal stress.

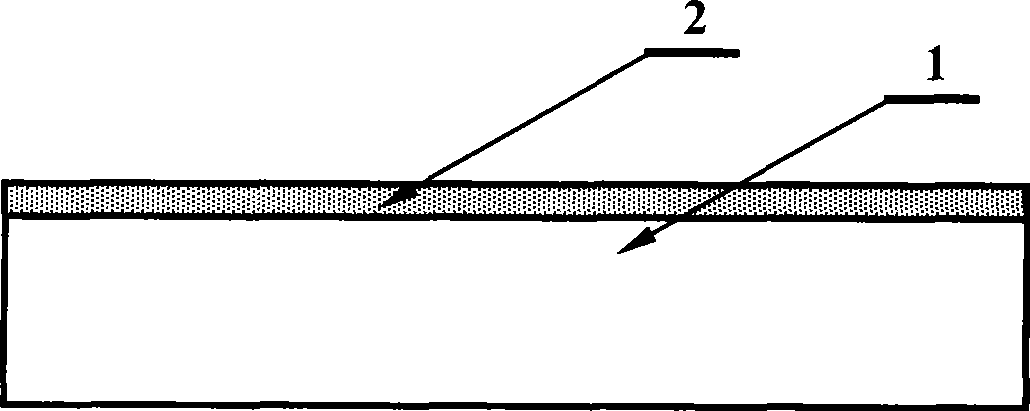

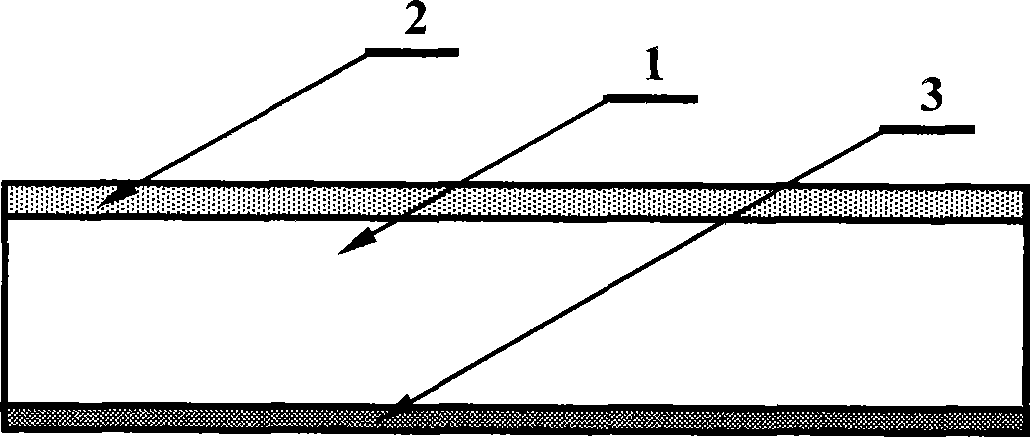

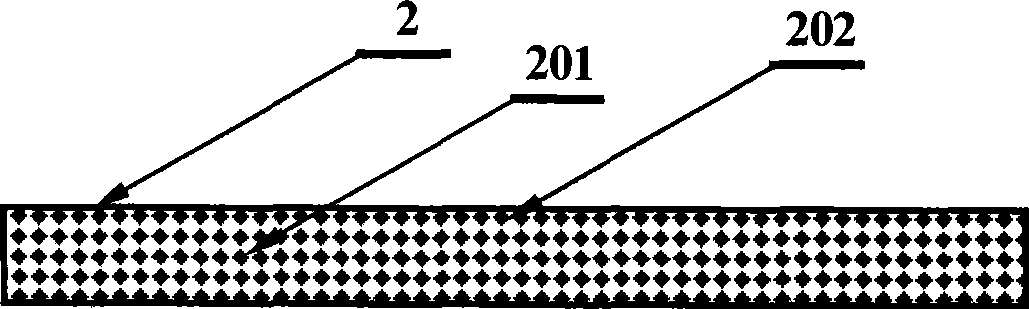

[0040] In the present invention, the graphite sheet 1 with high thermal conductivity is used as the heat conduction and heat dissipation material of the thermal device; the flexible heat conduction layer 2 with flexibilit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com